Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Water

Running Dry

Companies supplying water treatment chemicals struggle to find the right role in an increasingly water-stressed world

by Alex Scott

July 23, 2013

| A version of this story appeared in

Volume 91, Issue 29

For years, the 200 inhabitants of Bokola, a group of five villages in Malawi, Africa, faced ill health because their only water came from either a dirty river or a hole in the ground. Contaminated water contributes to the deaths of two or three village children each month, says Dave Bichael, a 27-year-old farmer from Bokola. Only in the past few months, after the English charity WaterAid bored a hole that reached an aquifer, have the villagers had access to safer water.

The World Health Organization and the United Nations estimate that almost 800 million of the world’s 7.1 billion people do not have access to potable water. Many people in the cities and rural communities of developing countries struggle to find enough water to drink. If it is available it is often dirty, and drinking it kills 2 million people every year. Population growth, increasing consumption of water per person, and less predictable rainfall resulting from climate change are all making the problem worse.

And this is not only a problem for the poor. In some developed countries, increased competition for water from activities such as hydraulic fracturing to release shale gas is also placing greater strain on water resources.

“By 2025, 3.5 billion will live in a water-stressed area,” says Christophe Gay-Bellile, Dow Chemical’s commercial manager for water and process solutions in Europe, the Middle East, and Africa. “Everyone agrees that there is a need for more water and better water quality.”

Water scarcity continues to present the greatest challenge in the developing world. Although large infrastructure-intensive water systems may be normal practice in industrialized countries, they are too expensive for many developing nations to install and operate. In his 2011 book “The Big Thirst,” Charles Fishman reported that the U.S. spends about $29 billion every year to maintain its water and wastewater plants. The developing world doesn’t have this kind of money.

Chemistry-enabled cleanup and recycling of dirty water for collection and storage systems will play a key role, water scarcity experts increasingly acknowledge. Indeed, the overall water treatment and supply business is worth about $450 billion and is “booming,” according to GE. The field is a fertile one for job-hunting chemical engineers and chemists (see page 33). Technologies being implemented in the developing world include small-scale or portable filtration units and even oversized drinking straws that can filter out contaminants from water drawn directly from a polluted river or pond. Collecting rainwater in villages or towns rather than allowing it to run off is another key piece of the puzzle, experts say.

But implementing such an approach is complex and requires governments, nonprofits, and for-profit companies to work together. Some chemical makers accustomed to selling water treatment chemicals to large companies or utilities are struggling to operate effectively outside of their comfort zone.

“The real challenge is to put the pieces together in new types of systems and to think about innovations in our water management practices,” says David L. Sedlak, a professor of civil and environmental engineering at the University of California, Berkeley, whose studies include water resources in developing countries. “For example, we have the individual technologies needed to capture urban runoff, treat it to potable water standards, and use it to recharge aquifers. But the challenge of turning a source of pollution and flooding into a water supply will require a new system of water management.”

A further issue is that many chemical firms accustomed to servicing sophisticated industrial water treatment systems aren’t able to make a profit from selling chemical products in developing countries where small-scale, low-cost water treatment is required.

“The problem is that you need to have a desalination plant first—and that might cost you more than $100 million to build—before you can use our products,” says David Cartmell, chief executive officer of BWA Water Additives, a Manchester, England-based water chemicals company. The privately owned firm supplies performance chemicals such as membrane-cleaning substances for desalination plants.

Building large, sophisticated plants that consume a great deal of energy is simply not feasible for many countries. “Sub-Saharan Africa does not have the cash,” Cartmell says. In contrast, countries in the Middle East “continue to invest in significant new desalination capacity,” he says.

Companies that have tried to provide high-specification water treatment chemicals and combine them with commodity products have generally not succeeded, Cartmell adds.

Finland’s Kemira is another producer of water treatment chemicals that has identified hurdles preventing it from working with water suppliers in developing countries. According to Riikka Timonen, the firm’s director of sustainability, the regulation, law enforcement, and public financing needed to build water treatment infrastructure are all lacking. “Chemistry alone is not enough; you also need other players in the ecosystem—most importantly, the infrastructure and regulation framework supporting the use of chemical water treatment,” Timonen says.

Any solutions from industry must meet the needs of developing countries at a cost that is affordable, water charities say. Many of the solutions being introduced today among rural communities in developing countries are based on simple technologies such as boreholes. Such technologies are the cheapest to install and the easiest to maintain, says Joseph Pearce, a technical adviser at WaterAid, which drilled the borehole in Bokola.

Positive Greenwashing

The laundry detergent giants Procter & Gamble and Unilever are looking for ways to reduce water use both in their manufacturing facilities and by the consumers who use their products.

In 2012, P&G hit a five-year goal when it decreased overall water use by 20% to 78.6 billion cubic meters on sales of nearly $84 billion. It is targeting further reductions at its locations where water stress is greatest.

P&G also wants to enable its detergent customers to use less water. An example is Downy Single Rinse, a fabric softener that reduces the amount of water needed to hand wash clothes by up to two-thirds by removing soapsuds in a single rinse. P&G designed the product specifically for developing countries where water is scarce. “We will continue to look for opportunities like Downy Single Rinse to conserve water in those regions where it is increasingly difficult to find,” the firm says.

Unilever, which has annual sales of $66 billion, also has developed a one-rinse detergent for water-scarce countries. Such a product is important because around 38% of domestic water is used to clean clothes, the firm says. Around 500 billion L of water would be saved if all Unilever customers in Asia and South Africa used its one-rinse detergent, the firm says. Unilever says it aims to provide 50 million households in water-scarce countries with laundry products that reduce water use by 2020.

In association with the U.K.’s Royal Society for Chemistry and the University of KwaZulu-Natal in Durban, South Africa, Unilever has also embarked on a research program to determine if nutrients in the waste laundry water associated with its detergents can be used sustainably on household food crops in developing countries. Initial studies showed that spinach and green pepper plants irrigated with so-called gray water had a significantly higher growth rate than plants irrigated with tap water.

Pearce recognizes the potential benefits from sophisticated technologies, such as miniature filtration systems installed in boreholes to remove pathogens, and chemicals that ensure collected rainwater is safe to drink. But a simple system that works is better than a complex one that doesn’t. “The problem with a portable filtration unit is that it might go out of use after about six months or a year, and then the whole thing might have to be replaced,” Pearce says.

The solutions are also limited by how much the poorest can afford to pay. The UN Development Programme recently estimated that nearly two-thirds of people who lack safe drinking water live on less than $2.00 per day, and one-third live on less than $1.00 per day.

While the developing world’s need for low-cost technologies is rising, funding for research into such technology appears to have been falling. Federal funding for seawater desalination research in the U.S. is now one-tenth what it was in 1967, after adjusting for inflation, and research associated with water reuse is one-twentieth of what it was in 1967, Sedlak says.

The European Union is responding to the need for innovation in water treatment by stepping up its funding for research in the field. The region’s Horizon 2020 program includes a series of projects dedicated to water scarcity. One goal is to help potential water treatment innovations move from the lab to the more expensive pilot testing phase, says M. Antonia Morales Perez, innovation manager for CEFIC, the European chemical industry’s main trade association.

The drawback for the developing world is that the European Commission’s water projects are focused mainly on water scarcity issues within Europe. “But I think some of the technologies should be applicable to developing countries,” Morales Perez says.

Some say chemical firms could be doing more to develop novel water treatment technologies. “I would like to see chemical companies performing more aggressive research studies to solve water pollution problems at lower costs so that developing countries can take advantage of it,” says Blanca Jiménez-Cisneros, director of UNESCO’s Division of Water Sciences. “Also, chemical companies could contribute more to help create institutional and human capacity to properly use chemicals to produce a safe supply of water,” she says.

Although technological and systems challenges remain, there are signs that the transfer of technology from the developed to the developing world is about to get easier. “In general, there is greater interest in bringing in the business sector much more and combining this with traditional efforts so that companies can make a profit and water systems can be implemented,” says Mats Eriksson, program director for climate change and water at the Stockholm International Water Institute, a policy institute set up to combat the global water crisis.

For example, rainwater harvesting systems are being adopted in developing countries that could enable communities to collect water and direct it into underground reservoirs rather than let it run off into ditches. “This is where the chemical part can come in to make sure that the water is clean,” Eriksson says. The chemical part here could include filtration systems.

That’s good news for chemical firms that are active in providing solutions to the water sector, and particularly firms such as BASF, Dow Chemical, GE, and Pall Corp. that have developed filtration systems.

BASF, a German firm that is the world’s largest chemical company, has restructured its water chemicals business in recent months to reflect a focus on broad water chemistry solutions. “Clean water is the most important topic—the most pressing issue for our globe,” Andreas Kreimeyer, BASF’s board member responsible for research, tells C&EN.

BASF products such as antiscalants and surfactants typically go into large-scale water treatment plants in developed nations. But more of the firm’s materials are being adopted in developing countries. Increasingly, the firm is experiencing cases where chemistry and membranes in particular are “really enabling sustainable solutions,” says Matthias Halusa, vice president of BASF’s water solutions business.

One example is the company’s supply of polyethersulfone filtration membranes to the Swiss firm Vestergaard Frandsen to make LifeStraw Family, a product designed to filter pathogens from the water consumed by a family of five in a developing country for three years or more. Additionally, Vestergaard Frandsen makes LifeStraws, oversized drinking straws for individual use. The LifeStraw, which features a hollow-fiber membrane, can purify at least 18,000 L of water. The LifeStraw products are suited to the needs of the poorest people in developing countries because they are durable, easy to use, and don’t require an external source of energy.

BASF is working on other low-cost filtration membranes that could be used in developing countries, says Xenia Beyrich-Graf, senior vice president of research for BASF’s performance materials business. “We believe that products for sustainable development will generate sustainable profits. This is not an unaffordable technology,” she says.

The U.S. companies Dow and Pall likewise see good business prospects in both developed and developing countries. “We see significant opportunities in certain developing countries,” says Mitch Summerfield, general manager for process systems at Pall. The firm’s products for such countries include portable filtration systems that, like the LifeStraw, are durable and don’t require electricity.

One problem is that in some regions not even dirty water is available, says Dow’s Gay-Bellile. In such cases, drilling boreholes or piping in water over long distances may be required.

Recycling water is another option that avoids the cost and complications of long-distance piping systems. For instance, in Tarragona, Spain, Dow worked with local authorities to install a system enabling industrial firms to reuse water instead of taking it from the nearby Gaià River system. Before the project, the Gaià River was running dry; now it is flowing again, Gay-Bellile says.

China, in particular, is adopting water reuse, which it has dubbed zero liquid discharge. ZLD is often practiced in industrial parks, where water treatment standards may be stricter than in developed countries, Gay-Bellile says.

Encouragingly, even most countries in sub-Saharan Africa now have master plans for providing potable water, according to Gay-Bellile. The proposed solutions range from big desalination plants to systems for individual villages or households. At the small-scale end of the market, one of Dow’s partners in South Africa is developing mechanical systems that can be turned by animals to generate power for portable reverse-osmosis systems.

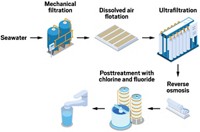

Reverse osmosis uses a semipermeable membrane to remove salt from seawater or brackish water. The process’s main drawback is its need for large amounts of energy to push water through the membrane. Dow and other firms have been improving the efficiency of their membranes with, for example, novel surface topographies that reduce energy needs and help prevent them from clogging.

Advertisement

Reverse osmosis has been the dominant desalination technology for decades, but an alternative electrochemical technology developed by Richard M. Crooks, a materials chemistry professor at the University of Texas (UT), Austin, and colleagues requires very little energy and has potential for use at small scale in the poorest regions of the world (Angew. Chem. Int. Ed. 2013, DOI: 10.1002/anie.201302577).

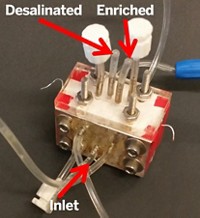

Developed in association with graduate student Kyle Knust and a team of researchers in Germany, the technology involves an electrochemical process in which a stream of seawater is split into two 50-µm-wide channels. An electrode at the split creates an electric field that forces positive ions into a branching channel, and the resulting charge imbalance forces negative ions to follow.

In this way, water flowing through the branch takes up dissolved salt, while water continuing through the main channel is partially desalinated. In contrast to reverse osmosis, only sand and sediment must be removed from the seawater prior to treatment. No membrane or further treatment such as disinfection is required.

“In principle, our device could be cheap enough for the developing world,” Crooks says. The research has been funded by the U.S. Department of Energy’s Basic Energy Sciences program. UT Austin has licensed its technology, which has a patent pending, to Union, Ky.-based start-up Okeanos Technologies, which is developing a product called WaterChip. The firm plans to sell its product globally but make it cheap enough to be used in the developing world, says CEO Tony Frudakis.

Water system equipment manufacturer Siemens is also investing in low-cost treatment techniques, according to P. John Brittan, technical director at Siemens Water Technologies. The firm is supplying low-pressure membranes for portable water filtration units developed by the SkyJuice Foundation, an Australian charity that provides low-cost water treatment systems for developing countries. The technology combines chlorine disinfection with solids removal via Siemens’ Memcor low-pressure membrane filter. The system, called the SkyHydrant, removes all pathogens to provide up to 700 L per hour of drinking water, the foundation says.

Charities such as WaterAid are wary of technologies that require high maintenance. However, SkyJuice claims that SkyHydrant operates under minimal pressure with no need for power. It is self-cleaning and doesn’t need conditioning chemicals or technical skills to run, SkyJuice says. So far, more than 1,500 SkyHydrant systems have been installed by nongovernmental organizations, community leaders, and local deployment partners in 23 countries throughout Asia-Pacific, Africa, Central and South America, and the Mideast.

End users are benefiting from SkyJuice’s new technologies. In 2012 SkyJuice provided the Sylvia Lasky Memorial School near Pursat, in Cambodia, with SkyBox, a portable water filtration unit featuring microporous, hollow-fiber polyvinylidene fluoride membranes. The SkyBox system has greatly decreased the number of water-bacteria-related diseases and symptoms in the school, says Sustainable Cambodia, a charity partnered with SkyJuice on the project. Approaches such as SkyBox illustrate how chemistry-based technologies can help provide water in developing nations where operating costs must be kept low. It’s just one of many low-cost water treatment technologies, coupled with local water collection and reuse strategies, that will be required as water stress grows in both developing and developed nations.

For Bichael, the Malawian farmer, and his wife and their two children, access to fresh water from the drilling of a simple borehole has markedly changed their lives. “If I could meet people who give us clean water,” he says, “I would show them how happy I am and I would pray to the Lord to love them more, because they have saved us.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter