Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Analytical Chemistry

Kicking Separation up a Notch

Ultra-high-pressure chromatography improves speed, resolution, and sensitivity of HPLC

by CELIA M. HENRY, C&EN WASHINGTON

November 22, 2004

| A version of this story appeared in

Volume 82, Issue 47

Many modern analytical problems cry out for fast and efficient ways to separate complex mixtures. For example, it's almost impossible to separate all the peptides in the protein digests used in proteomics samples.

One way to achieve faster, more efficient separations with liquid chromatography is by using smaller packing materials. That has been a challenge, because smaller particles require higher pressures to force the solvent through the column. Now, however, chromatography using ultra-high pressure has advanced to the market and is helping researchers achieve separations that were impossible before.

When high-pressure liquid chromatography (HPLC) was introduced in the early 1970s, columns were packed with irregularly shaped 10-µm particles. The pumps that forced solvent through the system operated at about 6,000 psi. By the mid-1990s, packing materials were more uniform and particle sizes ranged from 3.5 to 5.0 µm. The pumps still operated at 6,000 psi. Over that time, the performance of HPLC improved but at the cost of trade-offs among speed, resolution, and sensitivity.

James W. Jorgenson, a chemistry professor at the University of North Carolina, Chapel Hill, was one of the first people to move to smaller packing materials for liquid chromatography. There has been a "consistent trend toward smaller particles, but because of the pressure limits, it was always tied with making the column shorter," he says. "The ultimate benefit was very high speed but not any better performance. In fact, the performance actually got a little bit worse."

Certain column characteristics are improved by decreasing the particle size of packing materials. For example, a value called the theoretical plate height, which is a measure of column efficiency, is directly proportional to the particle size: The smaller the plate height, the better the separation. On the other hand, the optimum velocity through the column is inversely proportional to the particle size, so smaller particles mean that faster flow rates can be used.

"You should be able to operate at extremely high linear velocities and sacrifice little in terms of efficiency," says Milton L. Lee, a chemistry professor at Brigham Young University in Provo, Utah, who also works with ultra-high-pressure LC. However, high linear velocities require capillary columns to reduce the frictional heat produced, and capillary columns can be tricky for injecting samples, he says. "Injecting in capillaries is not as forgiving as injecting in a conventional packed column. Dead volumes become much more significant. If things aren't connected just right, you end up losing all that efficiency you gained."

Nothing comes for free, however. "The price you pay for all [these improvements] is that the pressure goes way up," Jorgenson says.

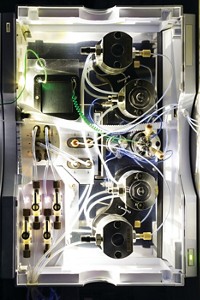

WORKING AT high pressures is tough. "You have to have leak-free valves and connections," Jorgenson says. "Doing that at high pressures is tricky." Chromatographers assume that injection valves will last for many injections before failing. Systems that work at 6,000 psi have to be completely redesigned to work reliably at 30,000 psi, he explains.

The systems that Jorgenson's group designed for proof-of-concept experiments border on the humorous, Jorgenson says. "We built a pair of syringe pumps that together probably weigh a ton. They're larger than the mass spectrometer we currently have them connected to," he says. "They're not very user friendly, but they'll work to 80,000 psi. They're reliable once you learn how to use them."

Learning to use the system was not easy. "There was an awful lot of work before we could get any chromatograms," Jorgenson says. "If you're going to do it, you have to be convinced it's worth doing and really stick with it. Picture a company where research is far more expensive to do. If someone hasn't shown there's some reasonable potential and maybe this is feasible, it would be really tricky to sell within a company."

When Jorgenson's group started presenting results at conferences, their work attracted the attention of the Milford, Mass.-based instrument vendor Waters Corp. The company approached Jorgenson about starting a collaboration, which culminated in a product called the Acquity (pronounced "acuity") UPLC System, which Waters launched at the 2004 Pittsburgh Conference. Waters calls the technique ultra-performance liquid chromatography, or UPLC, to distinguish it from conventional HPLC.

UPLC is based on the same theoretical underpinnings as HPLC, except that everything is taken to extremes. "My biggest worry was that the pressure would cause big changes in the retention mechanisms and make the technique worthless," Jorgenson says. "We were very happy not to see that."

Waters created a system from the ground up. The columns are packed with 1.7-µm particles. Besides being small, the particles also needed to be porous. To achieve that condition, the company uses hybrid organic/inorganic particles made by condensing 1,2-bis(triethoxysilyl)ethane and tetraethoxysilane. In these particles, ethane bridges silicon atoms in a silica matrix.

Waters scientists tried to combine the advantages of silica-based and polymer-based packing materials, says Marianna Kele, a senior scientist at Waters. "The particles have the silica backbone, but the silicon atoms are interconnected with ethyl groups," she says. "We still can keep the strength of silica, but we also add two important features: reduced silanol activity and improved resistance to alkaline mobile phases. It allows us to extend the useful pH range of the particles."

The columns are microbore, with inner diameters of 1.0 or 2.0 mm. So far, Waters offers only one type of column chemistry for UPLC that is applicable over a wide range of conditions. The company plans to expand the range of column chemistry options in the future, Kele says.

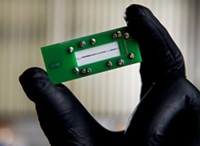

Waters also specially designed the hardware to operate at 15,000 psi. Company engineers redesigned the injector to withstand the increased pressure and to keep up with faster cycle times.

UPLC DELIVERS increased separation efficiency, which can be exploited in several ways. Each run can be shortened so that more samples can be analyzed in the same amount of time, or the run time can remain constant, with more components being separated.

Ian Wilson, a principal scientist at pharmaceutical company AstraZeneca, in England, is using UPLC to look for changes in metabolite profiles in response to different circumstances. He admits to being skeptical when he first heard about UPLC. Then Wilson saw the chromatogram from a sample of rat urine, and he "almost wept." Where he had been able to separate 2,000 components using conventional HPLC, he now can distinguish 10,000 components in the same time. Wilson is interested in both the increased speed and the enhanced resolution. "We want to profile quickly," he says, "but once we see differences, we want to do longer runs to really see the difference."

Daniel R. Doerge, a research chemist at the Food & Drug Administration's National Center for Toxicological Research in Jefferson, Ark., takes advantage of both the speed and the efficiency of UPLC separations. In one application, he uses UPLC to monitor the misuse of drugs such as growth promoters in animal husbandry. The people who misuse these drugs are "sophisticated pharmacologists," he says, and they can switch the drugs they are using to avoid detection of illegal use. "When you don't know what you're looking for, it's best to look for as large a number of compounds as you can," Doerge says.

In collaboration with epidemiologists, Doerge also studies how diet or drugs affect disease outcomes in humans. Because more compounds can be separated in a UPLC run, Doerge can look at diet and drug effects simultaneously. Because human studies often require large numbers of samples, sometimes thousands, throughput is critical, Doerge says. "The ability to do several hundred samples in a day if need be becomes very important."

What are the limits of pressure in UPLC? Jorgenson has worked with pressures as high as 105,000 psi. He believes that the high-pressure capabilities of commercial systems need to be increased in a stepwise fashion. "Right now, the approaches are very sophisticated, but they're technological extensions of the normal ways of doing HPLC. Some of the approaches to generating gradients and pumping at high pressures would have to undergo complete reanalysis and change," he says. "Fundamentally, I think somewhere around 100,000 psi would be a reasonable limit in the end, because you start to approach limitations of the tensile strength of materials."

Despite his role in helping Waters develop the Acquity UPLC system, Jorgenson hopes that other manufacturers of chromatographic equipment will get into the act. The sure sign that UPLC is catching on is when other instrument companies get projects going and get equipment out, he says. "I'm sure Waters would like to be the only one doing this, but in the long run that's really not a good sign."

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter