Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Storing Hydrogen In Polymer Pores

Polymers that inefficiently pack space adsorb significant quantities of hydrogen at 77 K

by Michael Freemantle

March 27, 2006

| A version of this story appeared in

Volume 84, Issue 13

Of all the materials that might conceivably be used to store hydrogen gas, organic polymers would not seem, at first glance, to be promising candidates. Nonetheless, they are now being investigated to see if they can store large quantities of hydrogen safely and economically for future hydrogen-fueled transport systems.

"Organic polymers have not been considered for this application until now because their molecules generally have enough conformational and rotational freedom to pack space efficiently," explains Neil B. McKeown, professor of organic materials chemistry at Cardiff University, in Wales. "As a result, they do not have large internal surface areas."

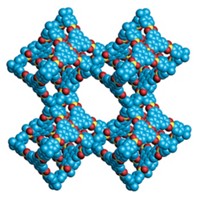

Rather than polymers, most scientists interested in gas storage have been exploring the use of microporous materials, which have large, accessible, internal surfaces for storing hydrogen by physisorption, or noncovalent adsorption, McKeown says. Zeolites, various forms of carbon, metal-organic framework compounds, and other types of porous materials offer attractive possibilities for such storage, he believes.

Two years ago, McKeown and coworkers reported the synthesis of a novel family of microporous polymers that have exceptionally high internal surface areas. The internal surface areas of these so-called polymers of intrinsic microporosity, or PIMs, are greater than 800 m2 per gram of material, "which is equivalent to the surface area of three tennis courts per gram," he observes. He developed the polymers with Peter M. Budd, a senior lecturer in chemistry at the University of Manchester, in England, and coworkers (Chem. Commun. 2004, 230).

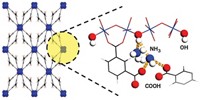

The materials are composed entirely of macromolecules consisting of fused-ring subunits. The molecules have highly rigid and contorted structures that prevent them from packing together closely in the solid state. The majority of pores within the materials have diameters less than 0.7 nm.

In the most recent work reported on these materials, the Cardiff and Manchester groups collaborated with the Hydrogen Materials Group at the University of Birmingham, in England, led by David Book, to show that the spacious interconnected free volume in PIMs can be used to store hydrogen (Angew. Chem. Int. Ed. 2006, 45, 1804).

The amounts of hydrogen that so far can be trapped in these polymers is not great, but they are comparable with loadings achieved in some other materials under investigation. The Department of Energy has set a goal calling for practical hydrogen-storage systems to be able to store 6% hydrogen by mass by 2010 and 9% by 2015.

The leading material for hydrogen storage at the moment is activated carbon. This nanoporous form of carbon holds up to 4% hydrogen by mass at 77 K at safe, readily achievable pressures such as 5-10 atm. "Zeolites can store up to 1.5% under the same conditions of temperature and pressure," McKeown notes. "The PIMs that we synthesized to date store 1.5 to 1.7% under these conditions"-loadings that are also comparable with the best achieved with carbon nanotubes and metal-organic frameworks.

"As far as we are aware," McKeown points out, "these are the first examples of polymers that store hydrogen by physisorption."

Other researchers reported in 2002 that certain conducting polymers can store hydrogen at loadings of 6-8% by mass, but these results so far have not been reproduced and are "probably erroneous," according to Yury Gogotsi, professor of materials engineering, mechanical engineering, and chemistry at Drexel University, in Philadelphia.

PIMs, on the other hand, offer an attractive combination of properties as hydrogen-storage materials, according to McKeown and his colleagues. The polymers are lightweight because they are composed only of light elements: carbon, hydrogen, nitrogen, and oxygen. The materials, the researchers point out, are also chemically homogeneous, thermally and chemically stable, and can be synthesized reproducibly.

"PIMs are generated through polymer chemistry, which means that we can control the chemical structure and hence the properties," Budd says. "It should thus be possible to optimize hydrogen adsorption by tailoring the chemical composition and microporous structure of the polymers."

The team investigated one PIM that is soluble in organic solvents and two insoluble network PIMs. "The soluble PIM is prepared by the dioxane-forming copolymerization of a hydroxylated aromatic monomer, a spirobisindane, and a fluorinated terephthalonitrile," McKeown explains. "Both monomers are commercially available. The insoluble network PIMs are prepared by using similar dioxane-forming reactions involving readily prepared cyclotricatechylene and chlorinated hexaazatrinaphthylene precursors."

Cyclotricatechylene is a bowl-shaped receptor monomer that leads to enhanced ultramicroporosity, according to McKeown. "It illustrates the control over microporosity that is possible with this class of material," he says.

"Based on the limited evidence we have so far, insoluble network PIMs adsorb a little more hydrogen than the soluble PIM," McKeown continues. "It would be very exciting to get a soluble PIM to take up more hydrogen because then you would have a solvent-processible material. This would allow fabrication of whatever shape of storage structure that you want-for example, thin-film coatings or beads"-and it would also make it easier to prepare composite materials. "No other class of potential hydrogen-storage material can be processed like this."

The use of PIMs for hydrogen storage is novel, comments Gogotsi. "I've not seen any reports on hydrogen storage in a polymer of that kind," he says. "Since no material is able to meet the expectations of the automotive industry at the moment, the search for new materials having a potential for reversible hydrogen storage and potentially capable of reaching the DOE target should be continued."

According to Gogotsi, there may be applications for polymers exhibiting only moderate hydrogen uptake. "In my opinion, porous polymers can be used in composites with other more efficient storage materials, such as carbide-derived carbons or metal-organic frameworks, to fill pores between particles and improve the volumetric hydrogen uptake, as well as for manufacturing hydrogen tanks of a complex shape," he says.

"Because polymers are built of light elements, they have a potential advantage over zeolites and metal-organic frameworks, which contain heavy elements," Gogotsi adds. "However, their pore volume and sorption capacity should be significantly increased to consider them as competitors to high-surface-area carbons."

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter