Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Semiconductors From Liquids

Method enables fabrication of circuit components starting from a liquid silane

by Mitch Jacoby

April 10, 2006

| A version of this story appeared in

Volume 84, Issue 15

A novel semiconductor-processing technique based on a liquid precursor to solid silicon may one day replace traditional vapor-deposition methods for fabricating microelectronic devices. The procedure, developed by researchers in Japan, may enable the use of low-cost ink-jet printing methods to manufacture large-area displays and other advanced electronic devices.

At the core of most modern microelectronic devices lies a silicon-based "brain" that's been painstakingly constructed via a variety of exacting and energy-intensive processes. Manufacturers often depend on procedures in which highly purified silicon is heated and vaporized in vacuum and then deposited on a support material to build up structures in a layer-by-layer fashion. The overall process generally involves multiple refining, deposition, and etching steps to convert the solid film into a functioning circuit component.

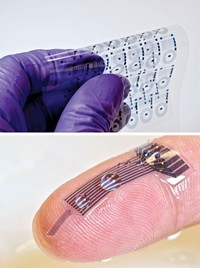

Simpler approaches using liquids could capitalize on today's high-resolution printing technology to "draw" fine circuit features with "inks" consisting of thin films of solution-phase semiconductors. Such procedures have been tried with solutions of organic semiconductors and other materials with limited success thus far.

Now a research team in Japan has shown that a silane precursor material, which is a liquid at room temperature and amenable to solution-phase processing, can be transformed chemically into high-quality solid silicon films, which can be subsequently incorporated into thin-film transistors (Nature 2006, 440, 783).

To form the films, Masahiro Furusawa and Tatsuya Shimoda of Seiko Epson Corp., Yasuo Matsuki of JSR Corp., and their coworkers irradiate cyclopentasilane (Si5H10) with ultraviolet light, thereby causing the room-temperature liquid to undergo ring-opening polymerization, which results in nonvolatile polysilane chains. The researchers then heat the polysilane to decompose the material and form a film of amorphous silicon. Because the amorphous material's charge-carrier mobility and other properties are unsatisfactory for electronic applications, the team treats the amorphous film with high-intensity UV radiation to convert it into a better ordered polycrystalline silicon film.

To evaluate the films, the researchers fabricated thin-film transistors and measured the devices' electronic properties. They find that simple spin coating, which amounts to squirting a bit of the liquid silane precursor onto a spinning support material prior to heating, leads to polycrystalline silicon films that are comparable in electronic performance with films prepared via conventional deposition. Thus far, however, the scientists find that their unoptimized (but more controllable) ink-jet procedures produce films that don't perform as well as spin-coated films, yet still tend to outperform films prepared from solutions of organic materials. They are fine-tuning the method and working to develop liquid-only fabrication procedures.

Describing the work in an accompanying commentary in Nature as "particularly exciting," Lisa Rosenberg, a chemistry professor at the University of Victoria, in British Columbia, says time will tell whether ink-jet printing of liquid silicon materials will provide the necessary resolution to pattern high-density integrated circuits and, ultimately, computer chips.

Regardless, she says, the method "will certainly allow the remarkably straightforward generation of simple, cheap, and flexible circuits for displays, as well as a range of other applications."

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter