Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Pharmaceuticals

Competitors Want to Get a Piece of Lipitor

Biocatalysis offers a variety of enantioselective routes to key chiral intermediates for the drug

by Ann M. Thayer

August 14, 2006

| A version of this story appeared in

Volume 84, Issue 33

COVER STORY

Competitors Want to Get a Piece of Lipitor

Atorvastatin, the active ingredient in Pfizer's cholesterol-lowering drug Lipitor, has a (3R,5S)-dihydroxyhexanoate side chain that accounts for about 25% of the compound's molecular weight. On a prorated basis, that would make the side chain worth roughly $3 billion, since sales of Pfizer's Lipitor exceed $12 billion per year. Fine chemicals producers are actually making much less money on intermediates used to construct that side chain, but they are still competing with routes to supply the 220-ton-per-year market for these building blocks.

Several "statin" drugs incorporate related 3,5-dihydroxyacid side chains, and about half come from microbial sources; those of Lipitor and AstraZeneca's Crestor (rosuvastatin), on the other hand, are synthesized. Making the side chain is challenging because it has two chiral centers, and greater than 99.5% enantiomeric and 99% diastereomeric excess are required. Biocatalysis has emerged as a versatile tool for achieving this and avoiding problems with traditional chemical routes (Angew. Chem. Int. Ed. 2005, 44, 362; Curr. Opin. Chem. Biol. 2005, 9, 188).

Developers have followed two major tacks, targeting either shorter intermediates in which just one chiral center is formed or longer chains in which both are generated. At a recent conference, Marcel Wubbolts, DSM's program director for white (industrial) biotechnology, compared several of the more notable routes. All generally provide enantioselectivities greater than 96%, he reported, but they differ in starting-material cost and complexity, the number of enzymatic steps, and the amount of follow-up chemistry needed to produce the complete side chain.

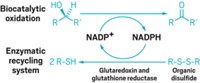

Both Daicel Chemical Industries and Kaneka have developed bioreduction systems for making ethyl (S)-4-chloro-3-hydroxybutyrate (ECHB) using either an alcohol dehydrogenase (ADH) or carbonyl reductase, respectively, and a second enzyme, glucose or formate dehydrogenase, to recycle enzyme cofactors. The first enzyme catalyzes the reduction of ethyl 4-chloroacetoacetate to ECHB. Similarly, Wacker Chemie and its partner J??lich Fine Chemicals (now a subsidiary of Codexis) have developed a process with an isolated ADH for making 3-hydroxybutyrate esters.

Using its gene-shuffling technology, enzyme technology company Codexis improved on the enzyme activity and stability in a similar ADH bioreduction. It also added a halohydrin dehalogenase enzyme that replaces the chlorine atom with a cyano group and yields a more advanced intermediate, ethyl (R)-4-cyano-3-hydroxybutyrate. The route, which Lonza uses for industrial-scale production, won a 2006 Presidential Green Chemistry Challenge Award (C&EN, July 10, page 24).

Dowpharma researchers have recently described their method, employing a nitrilase developed by Diversa, for the asymmetric hydrolysis of 3-hydroxyglutaronitrile to make (R)-4-cyano-3-hydroxybutyric acid (Org. Process Res. Dev. 2006, 10, 661). One advantage, says Karen Holt-Tiffin, Dowpharma's head of biocatalysis, is that the glutaronitrile starting material is produced from inexpensive epichlorohydrin. Whereas Diversa optimized the enzyme to increase its productivity, selectivity, and tolerance to higher substrate concentrations (J. Am. Chem. Soc. 2003, 125, 11476), Dowpharma used its Pfenex technology to express the enzyme in large quantities and economically scale up the process.

DSM and Daiso have developed processes in which dehalogenases resolve one enantiomer of 4-chloro-3-hydroxybutyronitrile from 1,3-dichloro-2-propanol via epichlorohydrin. DSM worked with enzyme developer Enzis (acquired by Codexis) on its version. Because the method is theoretically a resolution, rather than an asymmetric synthesis, the maximum yield is 50%. But since there is racemization of the epichlorohydrin intermediate, it behaves as a pseudodynamic kinetic resolution (see page 29). Still, the final enantioselectivity is a comparatively low 92%.

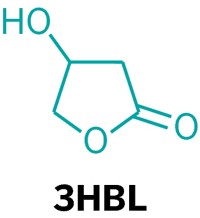

DSM also has developed an enzyme-catalyzed aldol condensation based on a 2-deoxyribose-5-phosphate aldolase (DERA). Major advantages are the formation of a six-carbon intermediate with both chiral centers in just one step and inexpensive chloroacetaldehyde and acetaldehyde starting materials. "There is no chemical way to easily reach the same target," Wubbolts notes. The process is very cost competitive, he adds, and DSM operates it on an industrial scale.

The aldolase transformation was originally described by Chi-Huey Wong and coworkers at Scripps Research Institute, La Jolla, Calif., about a decade ago. To scale up the process, DSM engineered DERA to make it more stable, 10 times more productive, and able to tolerate the starting materials. In 2004, Wong's group found a DERA mutant that accepts azidopropionaldehyde as a substrate (Tetrahedron Lett. 2004, 45, 2439).

In 2004, enzyme developer Diversa also found alternative aldolases by screening DNA libraries (Proc. Natl. Acad. Sci. USA 2004, 101, 5788). Using one of the improved enzymes, company researchers worked to address substrate inhibition as well. In the end, they reported a highly efficient, cost-effective, scalable, and enantioselective biocatalytic process that proceeded with an enantiomeric excess of 99.9% and diastereomeric excess of 96.6%.

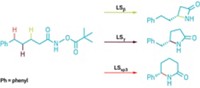

About a decade ago, Ramesh N. Patel and coworkers at Bristol-Myers Squibb (BMS) reported the double reduction of ethyl 6-benzyloxy-3,5-dioxohexanoate using a ketoreductase. Like the aldol process, it produces a larger (3R,5S)-diol intermediate with both chiral centers. The BMS group has more recently demonstrated the process with multiple ketoreductase systems for both ethyl and tert-butyl ketoesters (Tetrahedron: Asymmetry 2006, 17, 1589).

In the past, there has been some debate about whether chemocatalytic processes are more cost competitive than biocatalytic routes for the statin side chains (C&EN, June 14, 2004, page 47). Today, fine chemicals producers are saying that their biocatalytic processes can compete economically and environmentally. These factors are expected to be considerations as fine chemicals firms vie to supply intermediates now for Lipitor and within about five years for generic versions.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter