Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Boost For Battery Performance

Improved ordering in electrode material enhances charge-discharge kinetics

by Mitch Jacoby

February 20, 2006

| A version of this story appeared in

Volume 84, Issue 8

Lithium-ion batteries may get a shot in the arm, thanks to a modified version of a not-so-new material. Substituting one transition metal for another in the lithium compound commonly used in electrodes may boost the ability of future batteries to store and release energy quickly, according to a new study.

Because they pack more energy on a size and weight basis than other types of batteries, rechargeable lithium batteries corner the market in the portable electronics arena (C&EN, Feb. 13, page 79). Other types of products could benefit from lithium batteries' high storage capacity (energy density). But manufacturers have been slow to implement the batteries because for some applications-for example, heavy-duty portable power tools and hybrid electric vehicles-lithium batteries haven't generally been able to discharge or recharge quickly enough.

Now, a combined theoretical and experimental study finds that the charge and discharge rates of batteries featuring well-ordered lithium nickel manganese oxide [Li(Ni0.5Mn0.5)O2] electrodes are significantly faster than those employing the conventional electrode material, lithium cobalt oxide (Science 2006, 311, 977). The findings counter earlier studies in which the nickel-manganese compound had been judged to be a poor candidate for improving the performance of lithium batteries.

The new study was conducted by Gerbrand Ceder, a materials science professor at Massachusetts Institute of Technology; MIT graduate student Kisuk Kang and postdoc Ying (Shirley) Meng; and their collaborators at the State University of New York, Stony Brook.

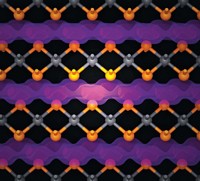

Lithium cobalt oxide (LiCoO2) and a variety of related materials under investigation for electrode applications exhibit a layered structure in which sheets of transition-metal cations are separated from layers of lithium by oxygen, Ceder explains. The layered structure is central to the charging and discharging mechanism, which is mediated by diffusion of lithium ions through the material.

"We knew from the theoretical investigation that in order to increase the rate of lithium diffusion, we needed a layered structure that was well-ordered," Ceder says. The group also determined that the size difference between the alkali (Li) ions and transition-metal ions governs the ordering of the layers. In the case of Li(Ni0.5Mn0.5)O2, because lithium and nickel are so similar in size, standard methods for preparing the compound led to materials with roughly 10% disorder due to Li/Ni site swapping. According to the researchers, that disorder is the source of the poor charge and discharge rates measured previously.

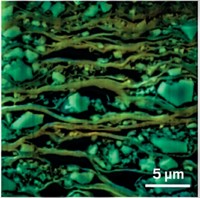

So the group prepared the sodium analog of the material to exploit the relatively large size difference between Na+ and Li+. When they exchanged the ions in the product, they obtained a well-ordered version of the lithium compound.

Describing the work as "excellent," Linda F. Nazar, a chemistry professor at Ontario's University of Waterloo, notes that "if the high degree of cation ordering, and hence excellent kinetics, is sustained on long-term cycling, this material could well prove important to the next generation of lithium-ion batteries, especially if direct synthetic routes are found."

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter