Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Keeping It Clean

The chemical industry is finding ways to secure and expand global water supplies

by Patricia L. Short

April 23, 2007

| A version of this story appeared in

Volume 85, Issue 17

WATER. It's one of the simplest, most abundant molecules in the world. Increasingly, though, water supplies are undergoing extreme swings. Violent storms and floods bring it in ferocious abundance. Or drought and desertification create crippling shortages.

Brief Chronicle of Clean Drinking Water

15TH CENTURY B.C.

Egyptians use a sedimentation apparatus and wick siphons with alum to remove free-floating solids from drinking water.

Hippocrates, the father of modern medicine, invents "Hippocrates' Sleeve," a cloth bag to strain water.

\

(1) 5TH CENTURY B.C.

Hippocrates, the father of modern medicine, invents "Hippocrates' Sleeve," a cloth bag to strain water.

(2) 3RD CENTURY B.C.

Roman engineers develop history's first aqueduct, delivering 130 million gal of water throughout Rome daily. Public water systems appear in several places including Rome, Greece, and Egypt.

A.D. 500-1600

Virtually no progress is made in water treatment.

1685

Italian physician Lu Antonio Porzio designs first multiple-layer filter system for water, using two chambers of upward and downward flow to strain sediment.

1854

John Snow, a London physician, suspects that water from the Broad Street pump is the source of a cholera epidemic. To test his theory, Snow reviews death records of area cholera victims and interviews household members. After he presents his findings to community leaders, the pump handle is removed, ending the cholera epidemic.

Roman engineers develop history's first aqueduct, delivering 130 million gal of water throughout Rome daily. Public water systems appear in several places including Rome, Greece, and Egypt.

\

LATE 1800s

Largely because of waterborne diseases such as cholera, dysentery, hepatitis, and typhoid fever, many children still die before the age of five and it is rare for people to live beyond the age of 50.

1887

MIT researcher Ellen Swallow Richards conducts first comprehensive study of drinking water. Her work leads to the first water-quality standards and construction of sewage treatment plants.

EARLY 1900s

Chemists at Maryland Health Department discover that the introduction of small amounts of chlorine to drinking water rids it of bacteria, viruses, and other microorganisms.

1908

A water treatment plant in Bubbly Creek, Chicago, is one of first to begin regular disinfection with chlorine.

1910s-20s

The use of filtration and chlorination is widely adopted in U.S. cities, contributing to a dramatic decline in waterborne disease epidemics.

1942

U.S. Public Health Service adopts first set of clean drinking water standards.

Calling for global action to assist the more than 1 billion people who suffer from a lack of safe water, the United Nations sets a target to halve the proportion of people without sustainable access to safe drinking water by 2015.

\

EARLY 1960s

More than 19,000 municipal water systems are in use throughout the U.S.

1974

Congress passes the Safe Drinking Water Act.

(3) 2000

Calling for global action to assist the more than 1 billion people who suffer from a lack of safe water, the United Nations sets a target to halve the proportion of people without sustainable access to safe drinking water by 2015.

SOURCE: American Chemistry Council

The mismatch of need and abundance reaches across the globe, from developed to developing countries. In the U.S., for example, water levels have dropped dramatically at Hoover Dam and Lake Mead, as a booming population draws heavily on water supplies. Meanwhile, the aquifers of the Great Plains are being depleted by irrigation.

Officials in Yemen, on the tip of the Saudi Arabian peninsula, are concerned about the dwindling water reserves supplying the capital city, Sanaa. A rapidly expanding population and increasing use of water for irrigation are fast drawing down the city's water reserves. In fact, officials there are beginning to contemplate moving the historic capital and most of its population to the Red Sea Coast, where desalination could maintain water supplies.

As Michael E. Campbell, chairman of Arch Chemicals, told the American chapter of the Société de Chimie Industrielle in September, water shortages affect 450 million people worldwide, and this number will grow with an ever-expanding human population.

Even where there is water, it's often too contaminated to drink without risking serious illness. The World Health Organization (WHO) estimates that about 1.2 billion people worldwide lack any access to clean drinking water and that 2 million people a year—many of them children and elderly—die because of drinking contaminated water.

Seeing both human need and, someday at least, profits, companies in the chemical industry have begun developing a wide range of technologies that can help secure safe drinking water for the world's poor. Usually the projects are offshoots of technology that companies are developing for profit-generating business.

Take arsenic contamination, one of the major culprits in impure water supplies around the world, for example. Far from being the deliberately deployed weapon of drawing-room murder mysteries, this element is a more insidious mass poisoner that can be an unanticipated result of good public health intentions.

In Bangladesh, deep wells that were dug in the 1950s and 1960s to help control the spread of cholera (a diarrheal illness caused by drinking surface waters contaminated with the bacterium Vibrio cholerae) had an unintended consequence that only later appeared. The aquifer water contained hundreds of micrograms per liter of naturally occurring arsenic, well beyond the international standard of 10 µg/L.

Even though the problem is widely recognized, an additional 4 million such tube wells were installed in Bangladesh in the past decade. The result is that as much as one-fourth of the country's population is drinking water containing 10 to 50 times the amount of arsenic that is considered safe.

And arsenic contamination is not just a problem for the Indian subcontinent. Even in parts of the U.S., drinking water supplies cannot meet the new more stringent standard of 10 ppb (10 µg/L) of arsenic, which was recently lowered by the Environmental Protection Agency from 50 ppb.

In fact, according to WHO, arsenic contamination affects tens of millions of people in more than 20 countries around the world.

ITS IMPORTANCE was highlighted this spring by the establishment of a new award in the field of water treatment. In February 2005, the National Academy of Engineering established the Grainger Challenge Prize to encourage U.S. development of technologies for improving living standards throughout the world. This first competition addressed the challenge of designing an affordable system to reduce arsenic levels in drinking water to below 50 µg/L.

The top prize, worth $1 million, was awarded to analytical chemistry professor Abul Hussam of George Mason University, in Virginia. Hussam was recognized for his design of a simple, inexpensive system for filtering naturally occurring arsenic from drinking water (C&EN, Feb. 12, page 19).

The second award, worth $200,000, went to a team led by chemical engineering professor Arup K. SenGupta of Lehigh University in Pennsylvannia, who worked with the Denver-based nonprofit organization Water For People to develop an alumina-based ion-exchange column that attaches to well pumps. The third award of $100,000 went to Procter & Gamble's Children's Safe Drinking Water Program, which has provided millions of sachets of the company's PUR water-purification chemicals to communities in developing countries (C&EN, April 17, 2006, page 39).

Hussam's systems now are being manufactured in Bangladesh, and thousands of them, each costing less than $40, have been distributed. Some already have been in use for five years without signs of diminished performance.

The technology addresses some of the concerns raised by nongovernmental organizations (NGOs) such as the U.K.'s WaterAid, whose consultants worry about the disposal of arsenic-laden wastes.

WaterAid, a charity established in 1980 by British water suppliers, teams with United Nations agencies such as Unicef to work with "the poorest of the poor," as David Williamson, a consultant with WaterAid, puts it. The organization's emphasis, he says, is primarily on nonchemical means of protecting water supplies. "We are looking at protecting water sources—springs, for example—to keep them clean. We are not looking at treatment, if at all possible—that's not sustainable," he says.

WaterAid also monitors the arsenic content of water from wells in the Indian subcontinent, South America, and wherever else there is a local problem. Williamson cautions that solutions to water issues can bring on their own problems. "The danger of removing the arsenic is that you then have to do something with it," he notes.

However, according to Hussam, the only materials that need disposal from his system are sand and spent composite iron matrix, both of which are indigenous materials. The only part that needs occasional replacement is the sand, which again, is locally available.

One of the 15 finalists for the Grainger Prize was chemical maker Rohm and Haas, which has developed a household-scale potable water treatment system to remove arsenic from contaminated groundwater.

Working with Hydrotech Engineering, Rohm and Haas developed an ion-exchange system optimized for cost, reliance on indigenous materials, performance, ease of use, and generation of nonhazardous residuals. The technology uses modified limestone as its media.

Between 2002 and 2004, Hydrotech had run two tests under an EPA contract testing limestone-based material for arsenic removal from drinking water in the U.S.

Hydrotech was a natural partner, says Kim Ann Mink, the global manager for Rohm and Haas's process chemicals potable water business. "We were looking for a technology partner who could provide us with limestone media that would make our solution cost-effective, which is critical for emerging markets," Mink says.

And even though her company was not one of the Grainger Prize winners, she adds, it is continuing with the Hydrotech partnership. Rohm and Haas has completed field trials in China and India of a prototype unit designed for household use.

The company is "continuing to evaluate all options to develop this system for the developing world and also looking at pockets of the developed world where this might be valuable," Mink says.

Arch Chemicals' involvement in a safe drinking water program reflects the company's relationship with P&G, to which it supplies the calcium hypochlorite in P&G's PUR sanitization sachets. The partnership focuses on provision of two household-level technologies to disinfect drinking water: PUR sachets and WaterGuard, a dilute chlorine solution developed by the Washington, D.C.-based Population Services International (PSI), the Centers for Disease Control & Prevention, and the Pan American Health Organization.

"We have provided more than 600 million L of safe drinking water over the past three years," says Charlotte Otto, global external relations officer at P&G.

For example, P&G donated millions of PUR sachets, which combine calcium hypochlorite with a coagulant, for the East Asian tsunami disaster relief effort, and millions more to families in Haiti, South America, and elsewhere. The companies work with the U.S. Agency for International Development (USAID), a government agency that provides economic, development, and humanitarian assistance around the world in support of the country's foreign policy goals.

The project works, in great part, because it has turned to social marketing partners. For P&G and USAID, the main partner for social marketing is PSI, which has outreach programs for PUR in eight countries and WaterGuard in 18 countries.

Among the lessons learned in the project, according to Arch's Campbell, is that "we have to provide people in undeveloped regions with simple, easy-to-maintain, water treatment systems that villages or even individual households can continue to operate when relief workers have moved on to other communities or other crisis-stricken regions."

WaterAid's recently published "Technology Notes" observes, "The treatment of surface water can be an expensive exercise and one which is difficult for communities to sustain without long-term external support. The ultimate water treatment, namely using chemicals, is not considered viable in sustainable community development."

Getting local buy-in, in fact, is crucial for water purification projects, aid workers contend. As Roberto Lenton, Albert M. Wright, and Kristen Lewis wrote in the 2005 UN Millennium Project report on water and sanitation, "Tempting as it can be for professionals to push their favourite technologies, it is imperative to respond to user demand as expressed in their preferences and their willingness to contribute to acquisition, operation, and maintenance of expenses. Even the poorest community should have to incur a cost in the form of cash or in-kind contribution toward the capital cost of the types of desired technologies."

THE SUSTAINABILITY of such a project, however, depends on being able to establish community water banks or hiring what Campbell calls "circuit riders" who profit from the sale of sanitizers and expertise to their neighbors in surrounding villages.

He cites projects that Arch is supporting in Guatemala, El Salvador, and Honduras, where three small rural villages traditionally drew their drinking water from polluted local rivers. The International Center Clean Water Initiative for Latin America is helping villagers install rainwater collection systems and communal tanks where water will be treated with chlorine-based sanitizers. In addition, International Center workers set up community water boards to train circuit riders to go from village to village to properly maintain these systems.

In some projects, Campbell says, well-respected locals are recruited to sell water-sanitizing agents to neighbors and instruct them on proper use. In return, the sales agents earn a profit and in effect become public health experts and advocates. "These self-sustaining and self-reinforcing microenterprises are vital because too many poor nations do not have effective public health networks in place, so job-creating grassroots efforts are literally life savers," Campbell says.

In the separation membranes field, Dow Chemical is reaching some similar conclusions, as it works to balance sensible business operations with philanthropy, notes Ian Barbour, general manager for Dow Water Solutions. The company formed DWS in September 2006, soon after its acquisition of the Chinese firm Omex Environmental Engineering.

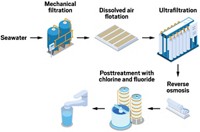

Following the acquisition, Dow's three workhorse technologies for water purification are ion exchange, reverse osmosis, and membrane technology in general. "I won't say these are expensive, but they require scale," Barbour says, adding that this poses a challenge, albeit a surmountable one, in getting such technology into small or rural applications.

"For example, you can do desalination now for 50 cents per cubic meter, but that depends on scale, requiring electricity or another power source and distribution. So it doesn't solve the problems of rural poor," Barbour acknowledges. Still, he believes that DWS can bring its technology to bear "for the base of the pyramid—people who can't afford anything but need a lot."

Working with Omex in China, DWS plans to pilot a new distributed water system that employs low-pressure membranes. "It seems to me this would make a difference. It would be profitable for the company but drive the economics so the people could afford it," Barbour adds.

Companies seeking to help the poor must consider the issues of sustainability and of how they bring their technologies to market, he says. "If you just put in a system, donate it, and then walk away, it won't be successful. As soon as it needs some repairs, for example, people won't be able to keep it going." Instead, Barbour says, a company must devise an in-depth business model that includes training local people to enable them to do repairs and maintenance. "We've seen similar programs like this work," he says.

Advertisement

An example he cites is WaterHealth International, in India, which is installing affordable potable water systems. Dow is an investor in WHI and supports the concept of working with an NGO to tackle elementary issues such as why people should be drinking clean water. Even that seemingly self-evident truth can be hard to get across to people who have not been drinking clean water for decades, Barbour points out.

Other companies have their own takes on the use of membrane technology for such microinstallations.

For example, Jeffrey M. Seibert, president of the water processing division at Pall, a manufacturer of water purification systems, says, "One of our initiatives has been to develop a pre-engineered membrane-based system to make it easy for small communities to implement clean water programs." Such a system could be brought into a small village to serve a few thousand people at a cost of around $225,000. That modest investment brings the cost to treat 1,000 gal of water down to between 20 and 30 cents, he says.

Thinking along similar lines, "we can use our membranes to purify water in small villages, especially membranes that work under low pressure," says Rich Franks, a manager of Hydranautics, the U.S. arm of Japanese filtration membrane maker Nitto Denko. One problem with installations in remote villages, though, is providing a steady source of energy to power pumps. Another problem is training people to maintain pump and power systems.

General Electric has found at least a partial solution to some of these problems with a portable membrane system powered by solar panels and requiring minimal maintenance. Earlier this year, GE signed a $93 million agreement to provide petroleum and biofuels developer Dynoil with solar energy modules and water filtration units that can be installed in rural areas of India and other developing countries in Southeast Asia and Africa.

The units, designed to provide 2,000 gal of water of clean water every day, will depend on 200-W solar units to power a hollow-fiber membrane system able to filter out viruses, bacteria, and parasites. DynGlobal, the Dynoil unit that will distribute the water purification systems, says the systems can draw water from existing wells and streams.

According to Jeff Garwood, chief executive officer of GE Water & Process Technologies, "By 2020, much of the world is expected to confront severe water shortages, and countries like India will face a lack of water coupled with unprecedented infrastructure issues, shifts in population, and rapid industrial growth rates."

OTHER PORTABLE units containing filtration membranes are also available. An Australian charitable group, the SkyJuice Foundation, has developed a number of small gravity-fed filtration systems intended to provide clean drinking water. The foundation's SkyHydrant technology depends on Memcor microfiltration hollow-fiber membranes from Siemens to filter between 2,400 and 6,000 gal per day, depending on the quality of the water going in. SkyJuice has distributed more than 300 units, including many in countries such as Sri Lanka, India, East Timor, Indonesia, and Thailand, which were hit hard by the tsunami of December 2004.

Despite the numerous NGOs and companies operating in the arena of water purification, "the problems are huge," Dow's Barbour says. "Right now, we are probably at the stage where the world is just starting to become aware of the problem."

As Arch's Campbell put it in September: "Ultimately, we are not a nonprofit, philanthropic organization. We see tremendous business opportunities in creating self-sustaining markets for water sanitizers and municipal feeder systems."

In fact, he concluded, "The effort to provide greater access to clean drinking water is a noble mission, and it is one that can benefit both from philanthropic efforts and the power of self-sustaining market mechanisms."

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter