Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Business

Big-Time Painting

The market demands paints and resins that durably protect the infrastructure yet are easy to use

by Alexander H. Tullo

September 17, 2007

| A version of this story appeared in

Volume 85, Issue 38

Motorists take for granted the bridges and overpasses they drive over every day until they see the tragic photos on the news after one has collapsed. They hardly think of oil pipelines when they fill up at the pump until one is shut down, quite likely due to corrosion. All of us expect the infrastructure to keep us safe and keep us moving.

Our unsung allies, without which these expectations would be dashed far more often, are protective coatings—the materials that help prevent metal-containing bridges, storage tanks, overpasses, factories, office buildings, and pipelines from succumbing to time and the elements. The companies that develop the technologies for such coatings are always trying to improve properties such as resistance to weathering and corrosion while making them less costly to apply and less taxing on the environment.

Despite its importance, the market for protective coatings is relatively small. The sector was worth $5 billion in 2005, according to the Global Coatings Report 2006, commissioned by Akzo Nobel, one of leaders in the field, and prepared by Euromonitor International. The entire coatings market was valued at $86 billion in 2005. By comparison, decorative coatings, the largest coatings segment, was a $39 billion business that year.

Typically, protective coatings are applied in the field by spray, roller, and brush. In the most challenging applications, such as a long, massive bridge over salt water, they are applied in three layers: primer, intermediate coat, and top coat. The properties of the coatings are largely determined by the resins used to make them.

According to Phil Phillips, managing director of Chemark Consulting, in Southern Pines, N.C., about 50% of protective coating formulations are based on epoxy resins. These coatings are normally sold as two-component, solvent-based systems. One component contains a liquid epoxy resin in which epichlorohydrin and bisphenol A have already been reacted together. The other component contains amine-based hardeners that cure the resin by cross-linking the epoxide groups.

These resins are durable, adhere well to surfaces, and are chemically resistant. They can be found in the bottom two layers of a protective coating, but particularly in the primer, which also contains zinc for corrosion resistance.

Polyurethanes, which serve as the basis for 20–25% of protective coatings, are also traditionally sold as solvent-borne systems with two components: a polyisocyanate and a co-reactant, such as a polyol. Polyurethanes tend to be colorfast and resistant to weathering and thus are favored for top coats. So are acrylics, which are used in waterborne, one-component paints and are present in 5% of protective coatings. Alkyds, once the predominant coatings resin, are still used as a one-component, solvent-based resin in about 15–20% of protective coatings formulations.

The most important function of a protective coating is warding off corrosion, Phillips says. He says buildings and stadiums that are only 30 years old can potentially be torn down because of structural corrosion problems. "There is always a wish to improve corrosion resistance," he says. "The best they have is not good enough, because you are protecting significant assets that you want to last as long as possible."

Brad Rossetto, director of global sales and marketing for protective and marine coatings at PPG Industries, one of the world's biggest coatings companies, sees the role that companies like his play as being far more important than merely selling paint. "We think of it as a noble mission because we have infrastructure that is aging in this country, and there is something PPG can do to contribute to its protection and refurbishment," he says.

Although corrosion resistance is the primary function of protective coatings, customers demand more than that from paint producers and resin suppliers. In particular, they want coatings that are cheaper to apply. According to Phillips, labor and metal preparation can drive up the cost associated with a gallon of paint from $100 "in the can" to $1,000 by the time it is applied. "If you have a large construction site, you have to put up scaffolding as part of the process," he points out.

One seemingly straightforward way to reduce labor cost is to reduce the number of coats that are applied while retaining coating performance. This goal, however, has proved elusive for the industry. "For the most part, where three coats are being used today, they are fairly stringent environments," Phillips says. "So far, in such environments, producers haven't been able to get the same performance with a two-coat system that they have with three coats."

Creating epoxy resins that retain their color as well as polyurethanes do would pave the way to reducing the number of coats, Phillips says. "If you can keep most of the epoxy benefits—such as toughness, resilience, and adhesion—and bring up ultraviolet resistance dramatically, then you would really have something," he says. "But that particular puzzle doesn't seem to work well." More promising, Phillips says, is eliminating the need for an intermediate coat by creating an improved polyurethane top coat.

Resin companies are indeed trying to develop such easier-to-use paints. For instance, Carl Angeloff, head of corrosion materials in North America at Bayer MaterialScience, a coatings resin supplier, says his company has been developing polyurethane coatings that eliminate the usual middle coat.

He explains that the purpose of the intermediate coat is to build up the thickness of the coating system, which ultimately ends up at a dry-film thickness of about 10- to 12-thousandths of an inch. About five years ago, he says, paint companies started to offer polyurethane top coats that leave a thick film over a zinc-rich primer, circumventing the need for the intermediate coat.

Bayer also has developed a polyurethane technology in which a single coat can do the work of two or more layers. Its one-coat technology is based on polyaspartics, which are aliphatic polyureas that react with the polyisocyanate in much the same way that polyols do. The polyaspartic coatings do not contain zinc. Instead, they achieve corrosion resistance through sheer dry-film thickness—anywhere between 6- and 40-thousandths of an inch.

Angeloff says the polyaspartic coatings do not contain zinc because incorporating the high-cost metal into such a thick coating would be prohibitively expensive. And without zinc, he admits, polyaspartic coatings are better suited to light-corrosion environments than harsh ones such as chemical plants. The new National Museum of the Marine Corps, in Triangle, Va., uses a polyaspartic coating, he says.

PPG's Rossetto says his company's polysiloxane chemistry is a potential route to fewer coatings layers. The company says a polysiloxane coating used over a zinc-rich epoxy primer can offer properties that exceed those of three-coat systems in onshore applications. The Peace Bridge, which connects Buffalo, N.Y., and Fort Erie, Ontario, uses such a system.

Another driver of materials innovation centers on reducing the time to complete big jobs. Time means money for industrial customers, notes Alan Pekarik, global business director for coatings, polymers, and resins at Huntsman Corp. "Project turnaround time is being considered in some cases on an equal level with material costs," he says. "The increasing costs of labor and downtime for a facility are causing increased scrutiny in this area."

Steven J. Harrison, director of marketing for Carboline, the protective coatings arm of paint maker RPM, says a quick turnaround is also important for a jurisdiction maintaining a highway. "They want to shut down a lane at night, do the blasting and the painting in an eight-hour shift, and then turn their bridge back over to the morning rush hour," he says.

In epoxy paints, incorporation of faster acting amine-based curing agents is one way to get the painting job finished more quickly. Pekarik says he sees increasing use of his company's high-end polyetheramine curing agents in outdoor and architectural applications.

According to Harrison, Carboline is developing epoxy coatings based on phenalkamine curing agents. In addition to fast curing times, he says, the phenalkamines make epoxies more tolerant of moisture and can enable them to cure at temperatures as low as 20 °F.

Low-temperature curing provides critical flexibility to end users in colder climates who don't want to limit their painting to late spring through early autumn, PPG's Rossetto says. "However you can extend the painting season clearly is a benefit. Part of that comes from coatings that are curable at lower temperatures," he says.

Bayer's Angeloff claims that these time and temperature trends both work in favor of polyurethanes, which he says cure more quickly and in a wider range of temperatures than epoxies and polysiloxanes do.

Although their products are expected to do more than just cover an unsightly surface, manufacturers of protective coatings face the same tightening of environmental regulations that the rest of the paint industry does. They are reducing the volatile organic compound (VOC) content of their paints by boosting the "solids" content, thereby using less solvent, or by eliminating hydrocarbon solvents altogether via the use of waterborne resins.

According to Angeloff, typical VOC levels in protective coatings are about 340 g/L, but the industry is trying to move to 100 g/L. Current federal regulations cap VOCs at 450 g/L for such applications, whereas California regulations, the most stringent in the country, already mandate 100 g/L.

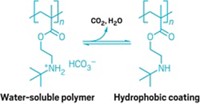

One way to meet VOC regulations is to eliminate hydrocarbon solvents altogether by switching to waterborne resins and coatings, points out Carlo Spaniol, global coatings marketing director at Dow Chemical. "If you can move to more water-based systems, which is not always easy in this market segment, you are addressing the increasingly stringent environmental legislation," he says.

But thus far, Angeloff claims, waterborne coatings aren't up to snuff for most infrastructural applications. "Generally, the waterborne technology has not been able to achieve the highest levels of performance required in many applications such as chemical plants and refineries," he says. Because waterborne resins don't cross-link as well as epoxies and polyurethanes, "they just don't develop the chemical resistance that is expected in severe-corrosion applications," he says.

Chemark's Phillips agrees. "There are a lot of water-based technologies being tried in this market, but they just don't perform as well as solvent-based systems," he says.

But waterborne coatings, particularly acrylics, are catching up quickly as protective coatings, argues Tim Wood, research director for industrial and maintenance coatings at Rohm and Haas. "It is still overwhelmingly a solvent-borne market, but waterborne has steadily been growing," he says.

This growth, he says, is being driven by VOC regulations and improvements in acrylic technology. Rohm and Haas recently launched its Avanse MV-100 acrylic resins line, which Wood says improves the performance of waterborne technology. Because the new products self-cross-link while they cure, they can be formulated into one-component coatings, unlike the two main competing resins. Moreover, he says, acrylics interact strongly with particles of titanium dioxide pigment and thus improve properties such as resistance to corrosion and weathering.

Wood says the products can be formulated not only into the top coat, where acrylics already compete with polyurethanes, but also in the intermediate coat and even in the primer. He admits, however, that the technology has its limitations. "If you are painting in a very difficult environment like an oil rig or a chemical plant, you might still tend to use solvent-borne coatings." He says the technology is ideally suited to medium-duty applications like water towers or factories.

Reducing solvents by making incremental adjustments to coatings formulations has been an effective way to meet regulations and has even extended the life of traditional alkyds. Once the workhorse resin in the protective coatings market, alkyds have persevered, thanks to the rollout of formulations that are "barely VOC compliant," according to Carboline's Harrison.

"For a while there, I thought they were going to become extinct because of the VOC issue," he says. "But there is still work being done in alkyds." Alkyds, which are formulated into one-component systems, are a favorite of end users who don't have access to sophisticated mixing and application equipment.

One way to reduce solvent levels in protective epoxy coatings, according to Dow's Spaniol, is to use low-viscosity bisphenol F-based resins instead of the customary bisphenol A resins. Likewise, Bayer's Angeloff says polyaspartic-based polyurethane systems can be formulated to contain anywhere from 40–100% solids.

Advertisement

According to Chemark's Phillips, there is a financial reward for paint and resin companies that work to develop new products for the highly demanding, yet relatively small, protective coatings market. He says profit margins in the industry can reach as high as 40%, versus about 30% for other coatings sectors.

And, Phillips notes, the industry is fairly fast-growing. By his estimate, the global protective coatings market is valued at $4.6 billion per year and is growing at a 5.2% annual rate.

He also points out that the growth varies strongly by region. The business in North America, a $750 million annual market where much infrastructure has already been built, is expanding at a modest 4% clip, according to Phillips. Emerging markets in China, India, and Eastern Europe, owing to the amount of infrastructure being built there for the first time, are growing at 9–11% rates, he says.

Companies have seen the growth of the Asian economies impact their businesses. "The boom in construction work in emerging economies such as China and India—and more and more in Eastern Europe—is impacting demand significantly," Dow's Spaniol says.

Even the mature North American market has been robust, observers say, thanks to a strong economy and high prices for oil and other commodities. "This industry is typically quite closely linked to the economic cycles," Spaniol says. "Right now, we are in a phase in which industry is performing very well. Companies are having good profit performance, and that translates into investments that boost protective coatings sales."

The renewed attention being paid to North America's aging infrastructure may also drive growth in the region. According to a report recently commissioned by NACE International, an association of corrosion engineers, some 15% of the 600,000 bridges in the U.S. suffer from corrosion. Public attention has been drawn to the country's aging infrastructure by the August collapse of the Interstate 35W bridge in Minneapolis and last year's closure of a BP oil pipeline in Alaska due to corrosion problems.

Spaniol cautions that such events won't necessarily translate into growth for protective coatings. "There is a lot of talk about the requirement for infrastructure, specifically in North America," he says. "The question is whether the government or other bodies fund it. There is a discrepancy between what needs to be done and what realistically can be done within the next couple of years."

It is unfortunate that the public has to be made aware of the sorry state of infrastructure in this way, Rossetto adds. "Sometimes it takes a tragic event to call attention to something."

- Big-Time Painting

- The market demands paints and resins that durably protect the infrastructure yet are easy to use

- Foiling Corrosion Involves Outsmarting Metals' Nature

- As soon as we are old enough to leave a bicycle out in the rain, we become familiar with the process of rusting

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter