Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Getting The Lead Out Of Bullets

Tungsten-tin composite provides alternative for hunters

by Jyllian N. Kemsley

November 26, 2007

| A version of this story appeared in

Volume 85, Issue 48

LEAD IS DENSE and ductile, has a low melting point, and is inexpensive, making it long prized for molding into ammunition. But it's also toxic to birds and other animals that ingest bullets and bullet fragments.

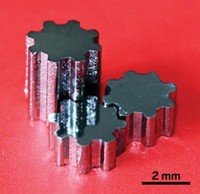

To address the need for less toxic ammunition with the same performance as lead bullets, researchers at Oak Ridge National Laboratory have now developed bullets made from a tungsten-tin composite material. ORNL has licensed the technology to WolfTech Manufacturing, Wakeman, Ohio, and the first bullets will be distributed by MDM Muzzleloaders, Maidstone, Vt.

Lead shotgun pellets for waterfowl hunting were banned nationwide in 1991 to prevent poisoning birds. In October, California banned lead ammunition for deer hunting in condor territory. Added restrictions on lead ammo are on the horizon in Missouri as well as other states.

The new bullets are made by compressing a mixture of coarse tin and tungsten powders at about 100,000 psi, under which the tin cold-welds to yield "chunks of tungsten in a sea of tin," says Richard A. Lowden, a senior research engineer at ORNL.

The grain size of the powders is critical: The tungsten particles must be small enough to distribute uniformly for a balanced bullet but large enough that they won't dissolve and create an environmental hazard. The tin particles can't be too small either, because they oxidize when exposed to air. Smaller particles have more surface oxide, which prevents bonding of the matrix. In the end, the optimal grain sizes are about 55 μm diameter for tungsten and 100 μm diameter for tin.

The composition that best mimics lead is 57% tungsten and 43% tin by weight. Compared with lead-free copper bullets, the tungsten-tin composites are heavier, enabling longer, straighter flight.

Used tungsten-tin bullets can be collected from shooting ranges and recycled. The low melting point of tin relative to tungsten means that the bullets can be melted, the tin poured off and repowdered, and the tungsten filtered and reused.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter