Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Intel, IBM Unveil New Transistors

Breakthrough: Hafnium-based materials will be incorporated in 45-nm-technology chips

by Alexander H. Tullo

February 5, 2007

| A version of this story appeared in

Volume 85, Issue 6

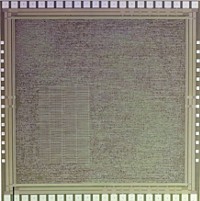

IN DUELING ANNOUNCEMENTS that mark the culmination of years of research efforts, Intel and IBM say they are using hafnium-based dielectric insulating materials to construct the transistors in their next-generation 45-nm-technology chips.

Silicon dioxide has been the transistor dielectric material of choice for about 40 years. As chip size has continued to shrink, the SiO2 layer has been made thinner and thinner to maintain adequate capacitance. In the most advanced chips in production today, which have 65-nm circuit lines, the SiO2 layer is only 1.2 nm thick.

But according to David Lammers, director of the WeSrch.com networking website for semiconductors—part of the semiconductor market research firm VLSI Research—a layer any thinner is prone to heat-generating electron tunneling. "You want a thinner electrical thickness, but you don't want all the current leakage and heat," he says.

Thus, in what it dubs the "biggest change to computer chips in 40 years," Intel is replacing SiO2 with a hafnium-based material for the 45-nm transistor. With their higher dielectric constants, or k values, hafnium compounds form a thicker gate that blocks electrons while maintaining sufficient capacitance.

And because the new high-k dielectric material is not compatible with conventional silicon gate electrodes, Intel is using unidentified metals as gate electrodes.

Intel says the new materials could stem the current leakage that occurs with SiO2 by more than 90%. And the company says the hafnium-based materials allow transistors to be scaled down enough to permit doubling their density on the chip.

A day after Intel's announcement, IBM said it had successfully made transistors with a hafnium-based high-k and metal combination with partners Advanced Micro Devices, Sony, and Toshiba.

Ghavam Shahidi, director of silicon technology at IBM Research, says that to incorporate high-k materials, the company had made a lot of progress in the past year in overcoming technical hurdles, such as maintaining a stable current in the transistor and optimizing the combination of metal gate and high-k material used in the transistor. "The whole industry has been looking for their high-k solution for a long time," he says. "We are confident we can use high-k [materials] at 45 nm."

Intel intends to be the first on the market with commercial 45-nm-technology chips by ramping up production at facilities in Oregon and Arizona at the end of the year and in Israel by the first half of 2008. IBM plans to incorporate its version of the new technology into chips next year.

Monica Peeters, product manager for high-k materials at Air Products & Chemicals, says it is encouraging that the semiconductor industry will use high-k technology in 45-nm transistors. Air Products offers hafnium precursor compounds such as tetrakisdiethylamidohafnium and hafnium tetrachloride for making the hafnium-based dielectric compounds through processes like chemical vapor deposition and atomic layer deposition. "It has been a long time in coming," she says. She notes, however, that hafnium- and zirconium-based high-k materials already have been used for capacitors in memory chips.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter