Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Polymerizing The Unpolymerizable

Two-step process leads to new class of polymers from bulky 1,2-disubstituted ethylenes

by Celia Henry Arnaud

February 12, 2007

| A version of this story appeared in

Volume 85, Issue 7

SOME PREVIOUSLY "unpolymerizable" molecules may not be so unpolymerizable after all.

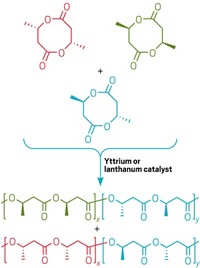

The conventional wisdom has long been that 1,2-disubstituted ethylenes with substituents larger than methyl groups are too sterically hindered to form polymers. If they react at all, the reaction takes a long time, and the yields and molecular weights are low. Even though the reactions are thermodynamically favorable, the molecules have difficulty getting in the right orientation to react.

It may be time to rethink that conventional wisdom. Materials scientist Christopher M. Snively, chemical engineer Jochen Lauterbach, and grad student Seth Washburn of the University of Delaware have shown that they can make thin polymer films from such supposedly unpolymerizable compounds (Macromolecules 2006, 39, 8210).

Since the late 1990s, Snively and Lauterbach have been developing a process for making thin polymer films. Their method involves depositing monomer vapor on a metallic surface cooled well below the monomer's freezing point. When the monomer hits the surface, it instantly forms an amorphous glass film. They then initiate polymerization by exposing the film to ultraviolet light. Because the deposition and polymerization steps are separated, the resulting films are uniform and have controllable thickness.

Snively and Lauterbach initially demonstrated the technique with such standard polymers as polystyrene and polypyrrole. To try something more challenging, they turned their method to 1,2-disubstituted ethylenes. They thought it would work because monomers in the glass film are not only randomly oriented but also locked into place, thereby making it more likely that normally sterically hindered reactions could proceed.

THEY CHOSE fumaronitrile, crotononitrile, and cinnamyl alcohol as their first examples because they wanted something simple to start with, Snively says. Since then, according to Snively, they have made nanofilms of about a dozen different 1,2-disubstituted ethylenes. The films range in thickness from several nanometers to several micrometers, depending on how much monomer is deposited. The molecular weights of the polymers range from 100,000 to 1,000,000, Snively says.

In the course of the research, they realized that many natural products are 1,2-disubstituted ethylenes. Snively suggests that their approach could open the way for making previously unavailable polymers from natural feedstocks.

Right now, however, the researchers can obtain only micrograms of the polymers. The small quantities of material available limit the types of characterization methods they can use. For example, they don't have enough material to try nuclear magnetic resonance spectroscopy. They are working on scaling up to gram quantities so that they can run this and other standard characterization techniques. "A gram would be a dream after working with micrograms," Snively says. As they try to scale up the process, the researchers plan to develop catalysts for making the films.

They will be investigating whether the new polymers could be used as coatings for electronic devices or plastic solar cells.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter