Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Interaction Yields

Academia and industry work together to foster new routes to chiral compounds

by Ann M. Thayer

August 4, 2008

| A version of this story appeared in

Volume 86, Issue 31

IN THE DRIVE to make chiral compounds, the ends can justify the means. About 70% of the new small-molecule drugs the Food & Drug Administration approved in 2007 contained at least one chiral center. So desirable are chiral molecules as pharmaceutically active compounds that scientists employ whatever methods they can and continually explore new ways to create their unique handedness.

Stereochemistry dictates how enantiomers interact with biological systems. Inasmuch as this determines whether a right- or left-handed pharmaceutical enantiomer does good or ill, manufacturers are further challenged to generate the desired one in high yield and purity.

There are many means to these ends. Effective, but sometimes wasteful, separations and resolutions are often used. Chemists also construct complex compounds on simpler chiral scaffolds. And they create chiral centers either indirectly by attaching chiral auxiliaries to control the stereochemistry or directly through metal, bio-, and organocatalysis.

Just as there are many routes to chiral structures, there are many starting points for innovation. Business and academic interests have long intersected in chiral technologies. Yet far from growing stale, these interactions continue to yield new catalysts and reactions.

Early innovations in asymmetric catalysis—coming from both industry and academia in the Nobel Prize-winning work of William S. Knowles, Ryoji Noyori, and K. Barry Sharpless—fueled many subsequent innovations in the field. Knowles's efforts led to the first industrial use of a chiral transition-metal complex to asymmetrically hydrogenate a prochiral substrate with high enantiomeric excess. In 1974, his employer, Monsanto, began using the process to make the Parkinson's disease treatment L-dopa.

Innovations by Knowles and by Henri B. Kagan in France prompted many others to further explore asymmetric hydrogenation and develop new chiral ligands. Tweaking the chemistry to enhance catalyst performance continues today.

For example, since 2000, University College Dublin (UCD) spin-off Celtic Catalysts has been pursuing P-chiral ligands like Knowles's DiPAMP. In these ligands, the chirality resides on the phosphorus atoms, where it will be close to the metal center, rather than on more remote carbons. This proximity to the center of action holds prospects for more selective and efficient catalysts, says Brian Kelly, Celtic's chief executive officer.

Although DiPAMP is a useful and no longer patented ligand, Kelly says it and related analogs, in which the catalysts can be "tuned" to work with different substrates, are not readily available because they are difficult to make. "So we decided to address the two issues—both the synthesis at large scale and the tunability—by making analogs," he explains. "Since no single ligand is going to work with every substrate, the more ligands you have, the better chance there is of finding one that will work."

Kelly and UCD professor Declan G. Gilheany founded Celtic to capitalize on more efficient ways to make P-chiral compounds. Gilheany and coworkers use a modified Appel method to produce P-stereogenic phosphine oxides by reacting racemic monophosphines with chiral alcohols (J. Am. Chem. Soc. 2007, 129, 9566). With just one added step, the resulting enantioenriched monoxides can be dimerized to bisphosphine ligands.

Two decades ago, Gilheany worked with Sharpless at Massachusetts Institute of Technology. Today, Sharpless, who moved to Scripps Research Institute in 1990, serves on Celtic's scientific advisory board. It's not surprising to find that many university and industrial scientists in the chiral field have common academic family trees.

Industry has also adopted the Nobel Prize-winning work of Sharpless. Rhodia ChiRex, now part of India's Shasun Chemicals & Drugs, licensed his asymmetric dihydroxylation process, while PPG Industries' former fine chemicals unit, now owned by Italy's Zambon, licensed the asymmetric epoxidation process.

In 2007, Celtic launched its first kit of DiPAMP-related ligands. It offers larger amounts on a price-per-kilogram basis, and it also uses them to make chiral intermediates. Moreover, Gilheany's route has proved useful for synthesizing chiral phosphorus-containing nucleotide drugs and enantiopure versions of organophosphorus agrochemicals.

Celtic is not the only P-chiral ligand supplier. Both Celtic and Johnson Matthey recently began offering trichickenfootphos, an asymmetric hydrogenation catalyst Pfizer developed for making its pain drug Lyrica. Switzerland's Solvias and Chiral Quest, created in 2000 and based on the work of Rutgers University professor Xumu Zhang, have commercialized P-chiral and other ligands.

Solvias is best known for its ferrocenyl structures, such as the Josiphos ligands that have been used for more than 10 years to make the herbicide metolachlor at the 10,000-ton-per-year scale. Solvias scientist Felix Spindler and Antonio Togni, now at the Swiss Federal Institute of Technology, developed the Josiphos ligands. Solvias also has collaborated with researchers at RWTH Aachen University, the University of Vienna, and catalyst producer Umicore to expand its offerings.

In recent years, fine chemicals firms and academic groups have worked separately and together to generate new families of chiral ligand structures that have put asymmetric hydrogenation on the map. Overviews of these wide-ranging families, which include atropisomeric, phosphine, phospholane, and P,N-ligands, can be found in the December 2007 special issue of Accounts of Chemical Research.

In the early 1980s, inspiration for other ligands grew out of Noyori's bisphosphine-binaphthyl ligand, BINAP. Noyori, formerly of Nagoya University and now president of Japan's Riken Institute, serves on the board of Takasago. The Japanese company licensed BINAP from Nagoya and has used it in a large-scale process for (–)-menthol. BINAP's effectiveness as a chiral hydrogenation catalyst, coupled with Takasago's refusal early on to sublicense it, drove others to invent their own catalysts. Takasago itself created the Segphos family.

By the 1990s, efficient catalysts with high enantioselectivity and expanded scope were emerging. Solvias had Josiphos, and Chirotech, now part of India's Dr. Reddy's Laboratories, licensed the bisphospholane ligands DuPhos and BPE from DuPont. Chirotech also had licensed catalysts for asymmetric allylic alkylation and allylic substitution from Barry M. Trost's lab at Stanford University and for asymmetric transfer hydrogenation from Japan Science & Technology Agency.

In addition to these straightforward licensing arrangements, industry and academia have long-standing chiral chemistry research collaborations. One example is the alliance between Evonik Industries' chemical business, formerly Degussa, and the Leibniz Institute for Catalysis (LIKAT) at the University of Rostock, in Germany. In June 2007, the two set up a $2.4 million, three-year agreement around new and optimized catalysts for existing Evonik processes.

Evonik's catASium chiral catalysts came from work with LIKAT and the Russian firm TatChemicals. "We want to take new knowledge from cutting-edge research and, if this knowledge is in line with our interests, transfer it quickly into the company," says Karlheinz Drauz, who handles international scientific relations for Evonik.

Facilitating this knowledge transfer are the more than 10 Evonik employees who also are university professors or lecturers. "They give young scientists insight into industrial practice and actively collaborate in scientific education," Drauz says. At the same time, he says, they can cultivate connections to the company on the part of young scientists and engineers.

Similarly, in the Netherlands, DSM Pharmaceutical Products encourages its scientists to be active in academia. For example, corporate scientist Hans E. Schoemaker has been a part-time professor at the University of Amsterdam for 15 years, and principal scientist Johannes G. de Vries has served part-time at the University of Groningen (RUG) since 1999. According to Ronald Gebhard, R&D director for DSM Pharmaceutical Products, the benefits of their university posts include being able to contribute to academic output while getting a look at new inventions and scientific talent at the early stages.

"DSM realizes that a lot of innovation takes place outside the company," he adds, and thus it teams up with many universities and small companies. When these efforts are successful, DSM may license the resulting technology.

"I am happy to pay royalties because it means there is income," Gebhard says. "But first you need to spend a lot of money, and it often takes years before you generate that income." Some universities, however, want substantial payments up front, before any investment has been made in developing and commercializing an invention. By doing so, Gebhard says, "the university system often kills potentially profitable collaborations."

DSM has had a long, fruitful relationship with RUG's synthetic organic chemistry department, headed by Ben L. Feringa. Together they developed the MonoPhos phosphoramidite ligands for asymmetric hydrogenation, which DSM uses in multiton manufacturing processes.

Similarly, interaction with the Applied Biocatalysis Research Center, in Graz, Austria, has given DSM the hydroxynitrile lyase technology for making enantiopure cyanohydrin building blocks, says Oliver May, DSM competence manager for biocatalysis.

Recently, DSM and Graz coworkers reintroduced pig liver esterase to the pharmaceutical chemicals market. Although its utility for hydrolyzing racemic esters into optically active carboxylic acids was known for more than 100 years, the natural enzyme was essentially banned from pharmaceutical applications after the outbreak of mad cow disease in the late 1990s.

To overcome this association with disease, they cloned, identified, and expressed a recombinant form in Pichia pastoris bacteria (J. Biotechnol. 2008, 133, 301). PharmaPLE, as they call it, avoids problems with animal extracts and in achieving consistent quality enzyme preparations, May explains. DSM makes the enzyme in large quantities to produce chiral intermediates.

Most fine chemicals manufacturers want to have the full toolbox of chiral technologies. "It is necessary to have a high level of in-house expertise in bio-, homogeneous, and heterogeneous catalysis and in high-throughput technologies to quickly identify suitable, tailor-made catalysts for solving our customers' chiral needs," Drauz says. Evonik, for example, has various options for producing amino acids and chiral building blocks: fermentation, chromatographic separation, and asymmetric chemical and biocatalytical processes.

"We work regularly with universities to continue to develop this expertise," Drauz says. "This gives us access to the latest scientific knowledge and allows us to develop new technologies a great deal faster. Time-to-market is decisive in this regard, and this is where university partnerships are a key factor in our success."

Small biotech companies that can focus on a technology and can advance it quickly are also sources of innovation, DSM's May says. To this end, the company works with IEP, a German biocatalysis firm, to access alcohol dehydrogenases for producing chiral alcohols. DSM will soon implement the technology on a multiton scale at ResCom, its manufacturing services unit, which helps launch new technologies.

Many small firms with roots in academic research are commercializing biocatalysts for making chiral intermediates and active drug ingredients. Improving the industrial utility of biocatalysts is a goal of CLEA Technologies. Founded in 2002 by Delft University of Technology professor Roger A. Sheldon, the company uses a patented technology for making cross-linked enzyme aggregates, which it has trade named CLEAs. Located on the Delft campus, CLEA Technologies has access to equipment and facilities that small firms otherwise couldn't afford.

"We're a small company, so we concentrate on what we do best, and that is developing novel and cost-effective biocatalytic processes and immobilizing enzymes for optimum performance," Sheldon says. CLEAs are made by precipitating enzymes from solution as physical aggregates and then cross-linking the reactive amino groups to form insoluble biocatalysts. The enzymes maintain their structure and activity but are easier to handle, separate, and recover from reaction mixtures. CLEAs also are stable in storage and use.

Making CLEAs doesn't require the laborious crystallization of highly pure enzymes. And unlike enzymes immobilized on supports, CLEAs are nearly all enzyme, which means high productivity. Tracking the scientific literature and enzyme sales shows which enzymes are being used in chiral synthesis, Sheldon says, and so the company offers commercially interesting oxidoreductases, lyases, and hydrolases.

Drug producers are using CLEAs to develop processes, Sheldon says. "None of these are at the ton scale yet, but some are at the pilot-plant scale." The company's largest request has been for 20 kg of a CLEA of the protease Alcalase, which is useful for synthesizing peptides and enantiomerically pure amines, alcohols, and acids via ester hydrolysis.

Advertisement

"One pharmaceutical company is using a CLEA in the final step of a synthesis for a drug in Phase III, and we're optimistic that that is going to be an important application," he says. In addition, Merck & Co. researchers have reported that hydroxynitrile lyase CLEAs can produce certain cyanohydrins in higher enantiopurities than chemocatalysts (Tetrahedron Lett. 2007, 48, 1473).

When a customer buys a CLEA, it automatically gets the right to use it. "That's the easiest way and the way most people want to do business with us," Sheldon says.

Sheldon isn't new to business, having spent 10 years in research at Shell and another 10 as R&D director at Andeno, later purchased by DSM. While at DSM, he was a part-time professor at Eindhoven University of Technology; he moved to Delft full-time in 1991.

"Some of the best communication between industry and academia is here in Holland," Sheldon says. "We tend to know what industry wants, and industry knows what people are doing in universities." CLEA Technologies participates in a national program called IBOS, for Integration of Biosynthesis & Organic Synthesis. Other participants include drug firms, DSM, and the spin-offs Syncom, from RUG, and Chiralix, from Radboud University Nijmegen.

In late 2002, Radboud University professor Floris Rutjes joined postdoc Richard Blaauw and an investor to found Chiralix, which offers chiral building blocks on the basis of expertise in bio- and chemocatalysis. DSM owns a 25% share, Rutjes says. "DSM has always funded at least one researcher in my lab since I started at the university." The companies have partnered with the idea that Chiralix can produce up to a few hundred grams of a material, and if customers choose to, they can work with DSM's ResCom to scale up further.

DSM also owns 30% of Syncom, started in 1988 by RUG professor Hans Wynberg. Another RUG professor, Richard M. Kellogg, purchased the company in 1996. DSM has supported many students in Kellogg's lab over the years. Since 2002, he has been a full-time Syncom director along with Ton R. Vries, who invented the Dutch Resolution process in 1997. Syncom does contract R&D in many aspects of organic synthesis and is known for its chiral capabilities.

Syncom employs an international group that now numbers about 140 people. "We have been growing 10–20% per year to meet customer demand," Kellogg says. The firm's manufacturing capabilities go up to a kilogram, with DSM offering above that.

Together Syncom and DSM developed and commercialized the Dutch Resolution process. A variant of the classical method for resolving racemates by forming separable diastereomeric salts, the method uses a family of resolving agents to inhibit nucleation of the more soluble salt and allow the less soluble one to precipitate. The technology is useful for small-scale resolutions in the early stages of product development, Kellogg says. "It's quick and effective, and very nice for resolving compounds for the first time."

Likewise, DSM and Syncom, along with the Groningen-based firms Xendo and Kiadis Pharma and researchers at RUG and Radboud University, formed the Ultimate Chiral Technology consortium in 2004. Supported by Dutch and European regional development groups, UCT's broad program, which formally ended in June, explored the basic science and new technologies in enantioselective catalysis, chiral analysis, racemate resolution, and chiral building block synthesis.

Earlier this year as part of the UCT effort, DSM and Syncom, working with Elias Vlieg's group at Radboud University and Donna G. Blackmond of Imperial College London, reported an intriguing way to resolve racemic conglomerates (J. Am. Chem. Soc. 2008, 130, 1158). In a commentary about the work (Nature 2008, 452, 161), J. Michael McBride and John C. Tully of Yale University called the work "the first original method for isolating single-handed crystals from a mixture of mirror-image forms since Pasteur used tweezers to effect such a separation in 1848."

The researchers ground racemic crystal mixtures of a chiral organic compound that were in equilibrium with a saturated solution in which racemization can readily occur. During the enantiomeric transformation process, which lasted several days, the chiral crystals continually break up and the "wrong" enantiomer racemizes in solution.

The end result is conversion to crystals of just one enantiomer using no resolving agents. Which enantiomer crystallizes can be controlled with chiral additives or a very small enantiomeric excess (ee), DSM scientist Bernard Kaptein explains. "If you start with just 3% ee of one enantiomer, you end up with 100% ee of it in the solid."

The coworkers were inspired by a similar phenomenon seen in achiral sodium chlorate by Cristobal Viedma at Complutense University, in Madrid (Phys. Rev. Lett. 2005, 94, 065504). The researchers have a second example that has been accepted for publication and a rationale for the phenomenon (Cryst. Growth Des. 2008, 8, 1675). They also have optimized conditions such that deracemization takes a day instead of weeks (Angew. Chem. Int. Ed., DOI: 10.1002/anie.200801846).

"We have tried it on a few selected amino acid derivatives," Kellogg says, "but I believe it is a very general phenomenon." Whether the process has any practical use isn't yet known. But perhaps the discovery will unfold in undetermined ways, he suggests. "Dutch Resolution developed in a manner different than we thought it would, and it broadened our knowledge so much that technologies have developed from it," he notes.

Although resolution is an old separation methodology, it is still used industrially, and industry-academe collaborations continue to refine the process. For example, rather than simply separating or resolving enantiomers, which means that at most half the product is the desired one and the other half is waste, methods that "recycle" or convert the waste enantiomer offer 100% theoretical yields.

Hydrolytic kinetic resolution (HKR) is a well-known process that was invented by Eric N. Jacobsen at Harvard University in 1997. In HKR, a racemic terminal epoxide reacts with water and a chiral catalyst consisting of cobalt and "salen" ligands. The reaction yields an enantiopure epoxide and a diol, which are easily separated. Rhodia ChiRex licensed HKR and sublicensed it to Japan's Daiso, which uses it to make epichlorohydrin and other intermediates. In 2007, Harvard granted Daiso and Shasun licenses covering newer, more active oligomeric metal-salen catalysts.

Another approach is dynamic kinetic resolution (DKR), which combines enantioselective enzymes with in situ metal-catalyzed racemization to convert one enantiomer. Piramal Healthcare, which acquired Avecia's fine chemicals unit in 2005, has developed its own resolution technology. Its SCRAM DKR method uses iridium catalysts to racemize alcohols and amines. Invented in-house, the process was developed further with a $750,000 grant from the regional group Yorkshire Forward and company matching funds. The 18-month project involved University of York and University of Huddersfield scientists and the catalyst developer Reaxa, a spin-off of Avecia and the University of Cambridge.

Recently, Piramal scientists combined SCRAM catalysts with diastereomeric crystallization—instead of enzymes—for dynamic thermodynamic resolution (DTR). "Enzymes work in certain cases, but not every case, whereas crystallization is a more widely applicable technique," Piramal Technology Director John Blacker says.

The company has showcased its DTR process on sertraline, the active ingredient in Pfizer's antidepressant Zoloft. "The process operated widely in the generics industry uses just a diastereomeric resolution, so there is more than 50% waste," Blacker says. "Our continuous DTR process takes that waste and turns it back into usable sertraline."

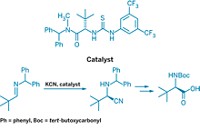

Piramal has had other long-standing academic collaborations. Its CACHy catalysts for the asymmetric synthesis of cyanohydrins came from work with Michael North at Newcastle University and Yuri N. Belokon of the Russian Academy of Sciences. The technology has been scaled up to make 2-chloromandelic acid, an intermediate that goes into several different drugs, including the antithrombolitic clopidogrel.

The company also has worked on asymmetric hydrogenation with John M. Brown of Oxford University and on asymmetric epoxidations with Varinder Aggarwal of the University of Bristol. A collaboration with Philip Page of the University of East Anglia has led to new chiral iminium salts for organocatalytic epoxidation of alkenes.

Piramal's innovation group, which operates within its R&D organization, handles most collaborative work with universities and other companies. Besides exploiting new technologies, the group focuses on particular applications. "We actively seek out new technologies where we can see opportunities," Blacker says. "This may be for molecules that we manufacture in-house or that our customers want us to make."

A goal of Blacker's has been to bridge gaps in understanding between industry needs and university capabilities. To this end, he splits his time between Piramal and the University of Leeds, where he is technical director of the new Institute of Process Research & Development. IPRD links Leeds chemistry and engineering faculty with industrial partners. Projects cover a wide range of areas such as synthetic chemistry, catalysis, materials characterization, and reaction and reactor design.

Advertisement

IPRD's "industrial club" includes at least eight companies in pharmaceuticals, agrochemicals, and fine chemicals. "They bring their problems and suggest really good generic areas in which to work," Blacker says. In turn, Leeds researchers propose projects, and if they are agreed upon, IPRD looks for public funding to support them. The goal is to develop technologies relevant to many partners that can be licensed nonexclusively and relatively inexpensively.

"Rather than having technology at a university and trying to find who we can get to use it, we want to be more focused on how to help industry," Blacker says. This doesn't mean developing products, but creating technology that he hopes "can be taken off the shelf and, with a minimum of effort, widely used and applied," he says. With teaching help from companies, IPRD also offers a master's degree in chemical process R&D to prepare students for industry jobs.

New models for collaboration are emerging, Princeton University chemistry professor David MacMillan suggests. Merck, for example, recently invested $5 million to set up a catalysis research center at the school, which put in another $5 million. The center houses automated high-throughput experimentation equipment similar to what Merck uses internally to find more efficient synthetic routes.

"It is very much in Merck's interest to help academics have the same expertise," says MacMillan, who heads the center. At the same time, "the benefits to university research have just been enormous," he says. Other major research universities are using corporate funding to set up similar centers. Before his move to Princeton in 2006, MacMillan, along with Robert H. Grubbs and Brian M. Stoltz, secured funding from the Gordon & Betty Moore Foundation for a high-throughput catalysis facility at California Institute of Technology.

Princeton's center is available to the university's researchers and will continue to grow, MacMillan says. His group uses it primarily for asymmetric organocatalysis, which uses organic compounds as catalysts, and has already solved a problem around the α-fluorination of ketones for Merck. Far from being fee-for-service work, MacMillan says the relationship with Merck gives academics the ability to explore their intellectual interests while solving industrial problems.

The α-fluorination reaction is a good example of that ability, MacMillan says, and shows the changes that new resources can bring to academic science in terms of speed and efficiency. "Almost overnight, using the robotic system, we came up with a new organocatalyst that works very well for a variety of systems," he says. "It's actually opened up a new line of chemistry that thematically fits into what my group does while immediately impacting Merck." He says Merck and other drug firms are already using the as-yet-unpublished results.

As a consultant to industry, MacMillan says he benefits not only from seeing what problems companies want solved but also from seeing common problems among companies or even within a given company. "There are reactions that if you could solve them would impact every company," he says. "For example, making carbon-fluorine bonds stereoselectively is a huge problem that is becoming much more widely worked on because of the understanding that the pharmaceutical industry needs it."

Organocatalysis is an extremely active field of research but hasn't yet had a major impact on manufacturing. Still, MacMillan point outs, the pharmaceutical industry frequently uses it. "It has been widely used in medicinal chemistry and now is moving into process chemistry," he says. "It's just a matter of time before a molecule makes it through development, and the route that goes with it is based on organocatalysis.

"I see movement toward organocatalysis because of the inherent benefits," he adds, which include readily available and inexpensive catalysts with low toxicity and no concerns about residual metals in waste streams or in drug products.

Initial adoption remains a major hurdle. "But if one company is successful in using organocatalysis, all the others will recognize that it has been validated and its use will blossom incredibly rapidly," MacMillan predicts. There's reason to believe he's right, because the evolution he expects for organocatalysis has happened before. The desire to have multiple and better routes to chiral compounds is now giving biocatalysis that kind of boost, just as it did for asymmetric transition-metal catalysis more than three decades ago.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter