Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Sunny Forecast For Fuel Cells

Novel electrode materials bring large-scale use of solar power closer to reality

by Stephen K. Ritter

August 4, 2008

| A version of this story appeared in

Volume 86, Issue 31

BY MOST SCIENTISTS' estimations, the only way to meet future global energy demand in an environmentally friendly way is by tapping into the sun's energy. Two research groups now report significant breakthroughs in electrode materials that may speed up the widespread use of fuel cells, which could be essential to a solar-powered future.

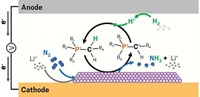

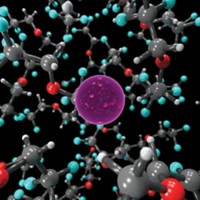

MIT's Daniel G. Nocera and Matthew W. Kanan devised a novel cobalt phosphate catalyst that forms in situ on the surface of an indium tin oxide electrode (Science, DOI: 10.1126/science.1162018). The catalyst is made from inexpensive cobalt salts and potassium phosphate buffer at neutral pH. The researchers demonstrate that even when using relatively small amounts of electricity, it can easily split water on one side of an electrolysis cell at room temperature to form oxygen. Hydrogen ions released in the process are transported by phosphate to the other side of the cell, where they are reduced to H2 at a different electrode.

Splitting water is a key step in realizing a large-scale method to collect energy from the sun using photovoltaic cells and storing it in the form of oxygen and hydrogen that can be later used to power fuel cells. The new cobalt-based electrocatalyst is a vast departure from expensive platinum-based systems that require strongly basic or acidic conditions, operate at high temperature, and may never be economically viable on an industrial scale. It sets up plain water "as a fuel for the future," Nocera says, "to be obtained under environmentally benign and low-cost conditions."

"Efficiently converting solar energy to hydrogen fuel by water splitting is a grand challenge, which could provide a fuel that is produced and used without harm to the environment," says materials scientist Ray H. Baughman of the University of Texas, Dallas. "The pioneering work of the MIT team on developing improved catalysts might be a key part of this energy solution."

The current density of the devices Nocera and Kanan prepared are still low because of the limitation of the current cell design, and the oxygen-producing electrode will need to be coupled into a larger system that also cleanly and inexpensively produces H2 . But the chemistry is solid, Nocera says, and he has "great faith" that chemists and materials scientists can optimize the design for commercial use, perhaps within a decade.

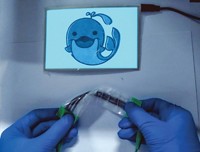

In a separate study, Douglas R. MacFarlane, Bjorn Winther-Jensen, and coworkers at Australia's Monash University prepared a new type of electrode that drives the water-splitting reaction in the opposite direction to reduce oxygen(Science 2008, 321, 671). Such electrodes are used in fuel cells running on H2 to produce electricity. The Monash team's three-phase electrode consists of an electrolyte layer, a thin layer of the inexpensive conducting polymer poly(3,4-ethylenedioxythiophene) deposited on a Gore-Tex membrane (a porous form of polytetrafluoroethylene), and air.

The researchers used a special vapor-phase polymerization method to coat the Gore-Tex membrane with the conducting polymer. The high surface area of the electrodes made with these polymer-coated membranes, when used in different types of devices, facilitates oxygen reduction at rates comparable with those of platinum electrodes, they report. And unlike platinum electrodes, the organic electrode is not slowed down by the presence of carbon monoxide, which can contaminate fuel cells.

"Replacing platinum with a conducting polymer is an exciting step forward in the quest to develop inexpensive catalytic electrodes for fuel cells and metal-air batteries," says UCLA's Richard B. Kaner, whose research focuses on nanostructured conducting polymers.

"The electrode is already suitable for low-current applications," MacFarlane says. "After scale-up to thicker membrane layers, it will also be applicable to high-power fuel cells."

In total, the accomplishments of the MIT and Australian teams "could have profound importance" in mitigating the growing energy-demand problem, Baughman adds.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter