Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Newscripts

Science Friction with Bob Wolke

by Science Friction with Bob Wolke

February 4, 2008

| A version of this story appeared in

Volume 86, Issue 5

I was kidding when I suggested in my Dec. 10 column that human adipose tissue might be converted into biodiesel fuel. But as it turns out, that has already been done.

Shane Graber of Archbold, Ohio, tipped me off to a story about Pete Bethune, a former oil exploration engineer in New Zealand who plans to circumnavigate the globe in 65 days in a specially built, $3 million trimaran fueled entirely by biodiesel. In addition to breaking the around-the-world speed record for powerboats (74 days, 23 hours, and 53 minutes, besting Jules Verne's Phileas Fogg by five days), his purpose is to highlight the viability of biodiesel as an alternative to fossil fuels. The boat is scheduled to sail on March 1 from Valencia, Spain.

I quote from earthrace.net, the official website of the expedition: "In an extraordinary show of dedication to the project, the skipper, Pete Bethune, underwent liposuction, and the fat (all 100 mL) was used to make a small amount of biodiesel for [the voyage]!"

In addition to Bethune's two-tenths of a pound of rather personal fuel, the boat will carry 3,000 gal of 100% biodiesel fuel and stop for refueling 12 times during the 27,600-mile journey. If each refueling were to start with an empty tank, the fuel "economy" would come to a minimum of 0.7 mpg, which isn't bad for plowing a 10-ton boat through expected 40-foot waves.

At this fuel consumption rate, how much of the journey will be powered by Skipper Bethune's lipids? About 100 feet. But I congratulate him for putting not only his heart into the project but his very self as well.

If you think Pete Bethune's seafaring safari is an over-the-top stunt, wait'll you hear this one. Bethune didn't have to eat caloric foods to manufacture his pinguid propellant. He could have used the fatty foods directly.

This past December, Andy Pag and John Grimshaw, two intrepid British environmental activists, drove from the Channel coast of England to the Sahara Desert city of Timbuktu, Mali, using only biodiesel fuel in their Land Cruiser SUV. And where did they get the biodiesel? From chocolate—surplus, leftover chocolate—something I didn't know existed. Not in my house, anyway!

How do you convert chocolate into diesel fuel? The compressed chemistry lesson on their website (green.tv/biotruck) is as unrefined as six-month-old deep-frying fat from a greasy spoon. It says whereas biodiesel is made from fat and alcohol (true), and whereas chocolate contains cocoa butter fat plus sugar, you just "distill the sugar to make alcohol," combine it with the cocoa fat, and you've got biodiesel.

Well, not so fast, guys. First, there's no sugar in natural chocolate until it is manufactured into a confection. And how do you distill sugar, anyway?

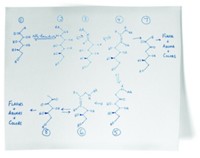

For any of my possibly organic-challenged readers, here is the chemical basis for converting fats to biodiesel fuel via transesterification.

Animal and vegetable fats are mostly triglycerides—esters of glycerol with three long-chain carboxylic (fatty) acids. The objective of biodiesel production is to convert the glycerol esters into methyl or ethyl monoesters of the fatty acids. This is done by reaction with methanol or ethanol, catalyzed by NaOH. The resulting mixture of monoesters works almost as well in a diesel engine as petroleum hydrocarbons do.

There are problems, of course. And I'll skip the politics and economics.

Used restaurant deep-frying oil, which is infinitely more abundant than unwanted chocolate, is the most common starting material for biodiesel. But it inevitably contains food particles, water, and free fatty acids, necessitating, respectively, filtration, drying, and titration to determine how much extra NaOH catalyst must be added. (How do you titrate an oil to determine its acidity? You first dissolve it in isopropanol.)

The NaOH is dissolved in an excess of methanol or ethanol (to force the reaction toward completion) and added to the oil or—I shudder to think—the chocolate. After lots of shaking and perhaps some heating, the mixture is allowed to rest for many hours, during which the other main reaction product, glycerol, settles to the bottom and can be drained off.

Oh, and fatty acids plus NaOH can make unpredictable amounts of soap, which must be "washed out" with some difficulty.

All things considered, I think I'll just continue converting my chocolate into energy by the time-honored, most direct route: eating it.

Bob Wolke can be reached at sciencefriction.wolke@gmail.com.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter