Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Greener Synthetic Pathways Award

by Stephen K. Ritter

June 29, 2009

| A version of this story appeared in

Volume 87, Issue 26

Eastman Chemical was selected as the winner of the Greener Synthetic Pathways Award for developing a biocatalytic process to make a family of long-chain esters from natural fatty acids for use in cosmetic and personal care products.

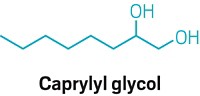

Fatty acid esters are an important class of emollients and emulsifiers that serve as specialty performance ingredients. Usually these esters are synthesized from fatty acids extracted from plant oils by using acid catalysts at high temperatures. But the harsh conditions can lead to undesirable by-products that add color or odor to the esters, which must be removed by using large volumes of solvent in energy-intensive purification steps. Growing pressure from the cosmetics market for all-natural and environmentally responsible ingredients has meant that chemical companies supplying the esters and other ingredients need to come up with better manufacturing processes.

Eastman's foray into making the greener esters got started a few years ago when a customer asked whether the company could produce esters from rice bran oil, which is rich in the antioxidant vitamin E, using only water or ethanol as the solvent. Eastman scientists responded by developing a biocatalytic process that uses immobilized lipase enzymes to make the esters—an organic-solvent-free process.

The enzymatic conversions and low reaction temperature minimize formation of the undesirable by-products, eliminate some chemicals, avoid energy-intensive isolation steps, and require much less energy. For example, one of the green cost-saving benefits of Eastman’s biocatalytic process is that it can reduceorganic solvent use by more than 10 L per kg of product. In addition, the gentler conditions allow a wider range of delicate unsaturated fatty acids to be used as starting materials, helping Eastman to produce hundreds of new esters, some of which are being evaluated for use in face cream, lip care, and sunscreen products.

"Eastman scientists continue to push past technological boundaries to create the green processes and products the cosmetic and personal care industry is searching for," comments Eastman market development manager James A. McCaulley.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter