Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Composite Anode Tolerates Hydrocarbon Fuels

Electrochemistry: Ceramic-metallic material could lead to cheaper, simpler fuel cells

by Jyllian N. Kemsley

October 5, 2009

| A version of this story appeared in

Volume 87, Issue 40

A new anode catalyst for solid-oxide fuel cells (SOFCs) can run directly from hydrocarbon fuels—a highly efficient process, but one that wasn’t feasible previously because untreated hydrocarbon fuels disable SOFC catalysts.

The new catalyst enables SOFCs to run at cooler temperatures than conventional cells and resists inactivation from carbon deposition and poisoning by sulfur contaminants in fuels such as natural gas and propane.

The work was carried out by a research group led by Meilin Liu of Georgia Tech (Science 2009, 326, 126).

“To my knowledge,” the study “demonstrates the highest output power at 750 °C of any known anode with sulfur tolerance,” John B. Goodenough of the University of Texas, Austin, says. “The finding is important for reducing the cost and allowing operation on natural gas at a lower temperature” than previously possible.

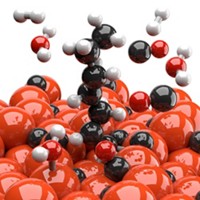

SOFCs generate electricity by electrochemically oxidizing oxygen ions with hydrocarbon-derived H2 or CO. For hydrocarbons used as fuels, SOFCs potentially offer much higher energy efficiency compared with combustion, Liu says.

SOFCs typically use an anode composed of nickel and yttria-stabilized zirconia. But naturally occurring sulfur contaminants in hydrocarbon fuels poison the catalyst. And fuels such as propane cannot be used directly in fuel cells with conventional SOFC catalysts because the hydrocarbons cause carbon deposition, or “coking,” that can block catalytic sites.

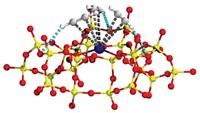

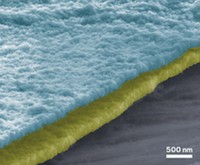

Liu and colleagues have now demonstrated that a composite anode prepared from nickel and a barium zirconate-cerate catalyst codoped with yttria and ytterbium (Ni-BZCYYb) performs better at temperatures below 750 °C than other SOFC anode catalysts. It also resists coking when dry propane is used directly as a fuel.

When H2 is used as a fuel, the new anode maintains its power output even when as much as 30 ppm H2S is added to the gas intentionally.

The pure BZCYYb material can also be used as the electrolyte in SOFCs. As an electrolyte, it has higher conductivity at lower temperatures compared with other commonly used electrolyte materials.

Being able to run the systems at lower temperatures reduces the cost of fuel-cell components, Liu says, and using BZCYYb both as the electrolyte and in the anode simplifies the fabrication process. The ability to avoid prior reforming of hydrocarbon fuels to H2 and CO would also simplify and reduce the cost of fuel-cell systems, he says.

Materials similar to BZCYYb have been used in proton-conducting fuel cells, notes John T. S. Irvine of the University of St. Andrews, in Scotland, so the novelty of the new work lies in using them with hydrocarbon fuels. Irvine adds that the nickel in the composite anode functions as the actual electrode, and the BZCYYb must act somehow to protect the nickel sites.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter