Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Preparing Large High-Quality Graphene Films

New methods could yield agile devices from carbon-based electronic material

by Mitch Jacoby

January 21, 2009

Two methods for preparing large high-quality films of graphene may lead to inexpensive, large-area electronic devices that can be flexed, bent, and folded. Such agility from ordinarily rigid and fragile devices could be exploited to make display and photovoltaic equipment that could be incorporated into clothing or folded for storage.

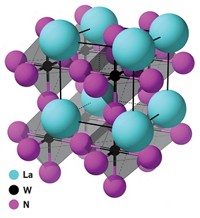

Graphene—one-atom-thick sheets of carbon that make up graphite—is widely studied because of its potential use in low-cost and flexible carbon-based electronics. Graphene's optical transparency and high electronic conductivity, for example, make it an attractive candidate for use in transparent electrodes.

Peeling apart graphite crystals to liberate individual graphene sheets leads to samples with outstanding properties. But that method is cumbersome and unsuitable for large-scale manufacturing. Graphene can also be prepared via self-assembly and chemical methods, but those techniques have not produced centimeter-sized high-quality samples. Now, two new methods can be used to prepare high-quality films measuring hundreds of square centimeters.

At Northwestern University, materials scientists Jiaxing Huang, Laura J. Cote, and Franklin Kim showed that corralling individual waterborne films of graphite oxide, a common graphene precursor, causes the films to coalesce into a single-layer, close-packed continuous sheet. In that study, which will be featured on the cover of the Journal of the American Chemical Society, Huang's group demonstrated that the product film can be readily transferred to a substrate and then reduced to high-quality graphene (DOI: 10.1021/ja806262m).

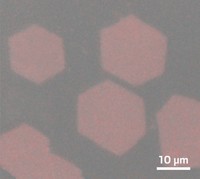

In the other investigation, Byung Hee Hong of Sungkyunkwan University, in Suwon, South Korea, grew centimeter-sized patterned graphene films by using chemical vapor deposition to react methane and hydrogen on a prepatterned nickel support. The group etched away the nickel with an iron chloride solution, transferred the films to other substrates, and showed that, even upon bending and stretching, the films retain their useful properties. Some of the samples exhibited a 30-fold decrease in electrical resistance compared with films made by other methods (Nature, DOI: 10.1038/nature07719).

Richard B. Kaner, a chemistry professor at the University of California, Los Angeles, notes that graphene has the potential to lead to a new generation of carbon-based electronic materials if methods can be developed to make it inexpensively, in large quantities, and with excellent electronic properties. "These papers represent very important contributions toward this goal," he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter