Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Building Zeolite Superhighways

Catalysis: Common treatments yield catalysts with exceptional openness and interconnectivity

by Mitch Jacoby

January 3, 2010

A sequence of common chemical treatments can modify the pore structure of zeolites, leaving each crystal with pores in three size ranges, according to a team of researchers in the Netherlands, Belgium, and France (Angew. Chem. Int. Ed., DOI: 10.1002/anie.201004360). The study demonstrates a simple way to customize porosity in crystals and may lead to new types of commercial catalysts.

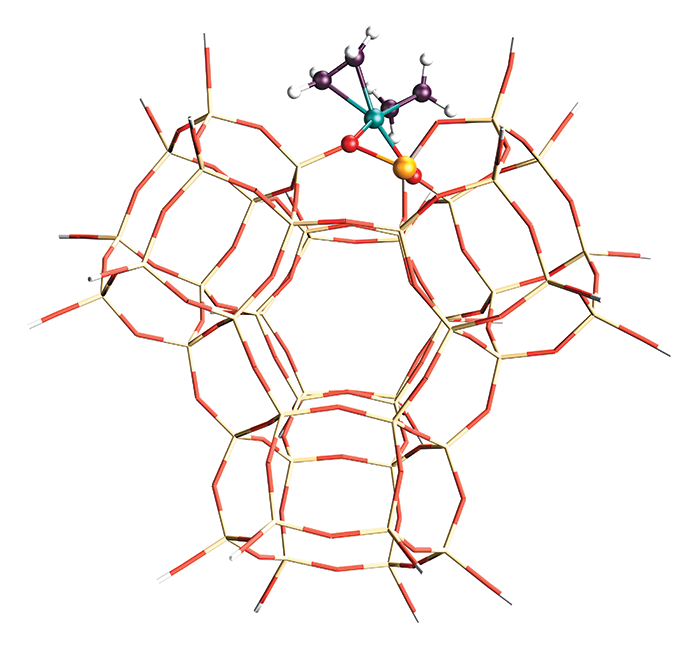

Zeolites are a class of porous crystalline aluminosilicates that are widely used as catalysts in oil refining and petrochemical synthesis. In zeolites, desired chemical transformations are generally mediated by catalytic sites located within micropores, and researchers have experimented for years with a variety of methods to tailor the pores to enhance the catalysts' performance and broaden their use.

A key challenge is that zeolites' short internal channels have diameters on the order of just 1 nm, making it difficult for a large flow of reactants and products to approach and depart, respectively, from catalytic hot spots in the crystals.

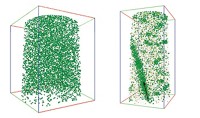

To accommodate a higher throughput of molecular traffic, scientists have come up with ways to prepare zeolites that are also endowed with mesopores, crystal passageways measuring many nanometers in diameter. Having a network of large pores that are open to the crystal's exterior interconnected with catalytic micropores in the crystal's interior is like having strategically placed superhighway on- and off-ramps connected to downtown avenues. The design avoids molecular bottlenecks and thereby boosts catalyst activity.

That type of pore engineering, which is based on synthetic templating and post-synthesis-modification methods, has met with success in just a limited number of cases. Few types of zeolites with the useful two-pore-size combination have been synthesized. And until now, no general methods have been reported for making zeolites that each have pores in three or more size ranges, despite theoretical predictions that such "hierarchical porosity" would benefit catalysis.

In the study reported in Angewandte Chemie, a team of scientists including Krijn de Jong and Jovana Zečević of Utrecht University, in the Netherlands, developed such a method for imparting "trimodal porosity" to zeolite Y. That zeolite is commonly used in petrochemical cracking, a process that breaks high-molecular-weight hydrocarbons into lighter ones.

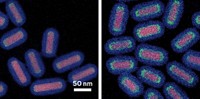

On the basis of electron microscopy, tomography, and other types of analyses, the team—which also includes Sander van Donk of Total Petrochemical's research center in Feluy, Belgium; François Fajula of Charles Gerhardt Institute, in Montpellier, France; and coworkers—showed that a combination of acid leaching, which dealuminates zeolites, and steam treating yields crystals with 1-nm micropores and large channels measuring up to 30 nm in diameter.

Treating those samples subsequently with alkaline solution, which leaches silicon, slightly increases the size of the largest pores and adds a network of medium-sized channels in the 5-nm range that are interconnected to the other types of pores, they report. The group also notes that in a series of catalytic-cracking tests, the "trimodal" zeolites outperformed control samples in terms of catalytic activity and product selectivity.

Because of the crucial interplay between chemical reaction and diffusion in zeolite crystals, this work is "certainly noteworthy," remarks Freek Kapteijn, a catalysis engineering specialist at Delft University of Technology, in the Netherlands. "The virtue of this study is that it combines relatively simple methods for changing the structural and catalytic properties of zeolites," he says. Kapteijn adds that although this approach may not be a panacea for all catalysts or reactions, it will likely inspire other advances in zeolite catalysis.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter