Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Scrutinizing Sunscreens

Lotions containing inorganic nanoparticles draw attention of toxicologists and ire of some consumer groups

by Lauren K. Wolf

August 8, 2011

| A version of this story appeared in

Volume 89, Issue 32

Brian Gulson knows sunscreens. For one thing, he lives in Australia, where the intense sunlight near the equator makes the protective lotions a necessary part of residents’ skin care regimens. According to the country’s Cancer Council, two in three Australians will develop some type of skin cancer by age 70.

For another thing, Gulson, now a retired environmental science professor from Macquarie University, in Sydney, has researched the safety of sunscreens. In fact, he found himself mired in a debate over the lotions’ safety last year, when the environmental advocacy group Friends of the Earth Australia cited his research to bolster its claim that consumers should steer clear of sunscreens containing nanoparticles.

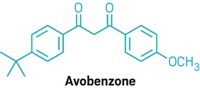

Some sunscreens contain zinc oxide or titanium dioxide particles that scatter and absorb both sunburn-causing ultraviolet-B light and potentially DNA-damaging UV-A light. In contrast with lotions that use UV-absorbing organic molecules as active ingredients, the particle-based sunscreens stand up longer to sunlight and typically cause less irritation among users with sensitive skin.

But when they contain large ZnO and TiO2 particles, these inorganic sunscreens scatter not only UV-A and UV-B rays but also visible light, giving them a white, pasty appearance on the skin. As a result, a lot of manufacturers have reduced the particle size to the nanoscale—about 100 nm or less—thereby causing the particles to become more transparent.

“Consumers are willing to apply a product that you can barely see” and “are more likely to apply it several times per day” to reduce the risk of skin cancer, explains Francis Quinn, director for sustainable development at personal care firm L’Oréal.

Although it has its benefits, nanotechnology also brings with it questions about whether the tiny materials interact with living cells and the environment in a harmful way (C&EN, March 14, page 44). In the case of particle-based sunscreens, scientists like Gulson have been working to address concerns about whether nanoscale ZnO and TiO2 materials pass through the outer layer of people’s skin to underlying cells and, eventually, to the bloodstream. In addition, work has focused on whether the tiny inorganic particles—particularly TiO2—act as photocatalysts and generate skin-damaging free radicals.

Despite the fact that researchers have been studying these issues intensely and most companies have put safeguards in place for their products, there has been an uproar over nanoparticles in sunscreens.

Like the uproar that enveloped Gulson.

In his controversial work, the Macquarie University professor had tested two types of sunscreen formulations on volunteers at the beach: One contained nanoscale ZnO particles that were about 19 nm in diameter, and one contained ZnO particles that were larger than 100 nm on average and therefore technically just outside the “nano” size range. Gulson and his team applied the lotions, which incorporated the nontoxic, nonradioactive isotope 68Zn, twice daily for five consecutive days to the skin of study participants and collected blood and urine samples (Toxicol. Sci., DOI: 10.1093/toxsci/kfq243).

What Gulson’s team found was that after two days, they were able to detect the isotope in all the volunteers’ samples, indicating that zinc from the particles, regardless of whether they were nanoscale or slightly larger, had been absorbed through the sunbathers’ skin. Friends of the Earth Australia now refers to this study in its “Safe Sunscreen Guide,” in which it recommends specific nanoparticle-free and “chemical-free” sunscreens for use, particularly on children.

“I’ve tried to make the point that the amount we actually saw in the blood was quite tiny,” Gulson says. For the volunteers who showed the highest absorption, for instance, the amount of zinc isotope circulating in their blood was three orders of magnitude less than the nonisotopic zinc in their systems. Zinc is an essential part of a large number of enzymes in the body, occurring there naturally.

In addition, Gulson says there is no proof that the zinc that got absorbed through the sunbathers’ skin was in the form of nanoparticles. “People whom I’ve spoken to in the cosmetic industry say that, given the pH of the skin,” which ranges from 5.4 to 5.9 in the outer layer, “the ZnO is probably broken down into soluble zinc ions,” he adds. Nonetheless, he concedes that more testing, over longer periods and on more skin types, is needed.

Nancy A. Monteiro-Riviere recently showed that ZnO particles only minimally penetrate into the dermis and lower epidermis layers of skin where living cells reside. Using both time-of-flight secondary ion mass spectrometry and transmission electron microscopy (TEM), the dermatology and nanotoxicology professor from North Carolina State University found that the inorganic particles stayed mostly in and on top of the stratum corneum, or outer, dead layer of the skin (Toxicol. Sci., DOI: 10.1093/toxsci/kfr148).

Monteiro-Riviere applied a sunscreen formulation provided by collaborators from Germany’s BASF that contained 60- to 200-nm-diameter ZnO particles to the skin of live pigs for 48 hours. Pigs have skin that behaves like human skin and are thus the best models for dermatological studies, she says.

What is unique about Monteiro-Riviere’s study is that she applied the inorganic-particle-based lotions to both normal pigskin and pigskin that had been sunburned. Most other nanoparticle skin penetration studies have so far shown that the tiny materials don’t pass through the stratum corneum of healthy skin. But Monteiro-Riviere wanted to know whether UV-B-damaged skin would still prevent nanoparticle penetration.

This is a common scenario, she says: “You’re at the beach, and you get a sunburn. You’re going to slap on some sunscreen” before going back to the beach.

With TEM, Monteiro-Riviere’s team saw that ZnO didn’t travel past the topmost layers of the stratum corneum—on average 20 to 30 layers thick—for either normal or sun-damaged pigskin. TiO2 particles that were about 90 to 460 nm in diameter traveled a bit farther, however: The tiny materials penetrated seven layers into the stratum corneum of normal pigskin and 13 layers into the stratum corneum of sun-damaged skin.

“Your skin is a very effective barrier,” Monteiro-Riviere says. Even with this small amount of penetration, “skin has a turnover every 30 days,” she adds. The particles, along with the dead skin cells, will likely just be sloughed off.

The U.S. Food & Drug Administration recently carried out a longer term study of TiO2 nanoparticle-based sunscreens on pigskin. After 22 days of application, the researchers observed only a few particles in the lower epidermis and dermis of the pigs (Toxicol. Sci., DOI: 10.1093/toxsci/kfq041). The team also used TEM to measure the average size of the thousands of TiO2 particles that had aggregated in the stratum corneum. The raw particles, which were 20–50 nm in diameter, formed clusters that were about 200 nm in diameter.

Other studies have also found that TiO2 and ZnO nanoparticles tend to aggregate. In sunscreens, even though “the individual particles are very small, the clumps of stuff on your skin are not going to be that small,” says Andrew D. Maynard, director of the Risk Science Center at the University of Michigan. “So there’s even less chance of them getting where you don’t want them to be” than would be the case if they did not aggregate.

Sensitivity about the safety of nanoparticles in commercial products has led some companies to take great pains to assess the particle-size distribution in their sunscreen formulations. “It took us more than a year to get it done properly and reliably,” L’Oréal’s Quinn says.

L’Oréal is quick to make the distinction that the TiO2 particles in its products are “nanopigments,” rather than nanoparticles, meaning that they are clusters. Although during synthesis the raw particles start at a size somewhere in the nano range, Quinn says, the average agglomerates in the final formulation are about 3–10 µm in diameter.

Other firms have managed to avoid the controversy over nanotechnology altogether by using inorganic particles that are micrometer-sized but still transparent in their formulations. For instance, Dow Chemical works with a supplier that makes transparent micrometer-sized ZnO particles, marketing dispersions of them under the brand name ZinClear. When asked how this is physically possible, Nilesh Shah, global R&D director for Dow’s home and personal care business, explains: “The particles actually are very microporous. So even though the nominal particle size is in the micron range, each particle has a lot of scattering centers at a much smaller size. It scatters very little on the visible side of the electromagnetic spectrum” and appears clear.

Using a large particle size also helps Dow steer clear of worries over the photocatalytic properties of inorganic nanoparticles. As particle size decreases, the materials’ surface area-to-mass ratio increases, making it possible for the crystals to react with UV light and water to generate reactive oxygen species such as hydroxyl radicals.

TiO2, especially, has a high propensity to generate free radicals when it exists in a crystal form known as anatase. Its other common form, called rutile, is much less likely to be photocatalytic. For sunscreens, “the best manufacturers” know this and “have actually engineered their particles to prevent free-radical production,” Michigan’s Maynard says. For instance, some firms use rutile TiO2 doped with manganese, and others coat their particles with alumina or silica to prevent photocatalysis.

But not all companies are conscientious. In 2006, patches of degraded paint showed up on precoated steel rooftops in Australia. The patches, in the shapes of handprints and footprints, suggested that the culprit might be the sunscreens that roofers were wearing during installation.

Philip J. Barker and Amos Branch of BlueScope Steel Research, in New South Wales, thoroughly investigated the phenomenon. The researchers applied a variety of commercial sunscreens to painted steel panels—designed to maintain their gloss for 25 years—and then exposed them to Australia’s summer weather for 12 weeks. After just six weeks, panels treated with one brand of sunscreen retained only about 13 to 17% of their gloss, whereas panels without sunscreen were unaffected (Prog. Org. Coat., DOI: 10.1016/j.porgcoat. 2008.01.008). Using X-ray diffraction, Barker and Branch determined that the suspect sunscreen contained a mixture of anatase and rutile TiO2 nanoparticles and that free radicals generated by the anatase TiO2 ate away at the paint.

Another study published in 2007 by researchers at University College London tested TiO2 particles extracted from commercial sunscreens on cultured human skin cells exposed to UV light. The team found that the sunscreens containing a mixture of anatase and rutile TiO2 particles killed two to three times as many viable skin cells as UV light alone—even when the particles were coated with what was meant to be a protective layer of silane molecules (J. Photochem. Photobiol. A, DOI: 10.1016/j.jphotochem.2007.04.014). Rutile TiO2 particles coated with alumina, however, actually protected the skin cells from damage.

Personal care firms aren’t required to specify the crystal form of the inorganic particles in their products. In the U.S., FDA recently released new regulations on sunscreen labeling that will take effect next year (C&EN, June 20, page 27). But they do not require that nanoparticles or their crystal forms be identified.

Despite concerns about the safety of nanoparticle-based sunscreens, the bottom line, NC State’s Monteiro-Riviere says, is that “we should wear our sunscreens” to protect against skin cancer—the leading type of cancer in the U.S., according to the American Cancer Society.

As Michigan’s Maynard points out, extended exposure to sunlight without using sunscreen “is always going to be a risk.” The best balance between risk and benefit, he notes, is the continued use of sunscreen for protection.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter