Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Parallel Printing At The Nanoscale

Lithography: Simplified patterning method reproducibly yields thousands of copies

by Mitch Jacoby

January 31, 2011

| A version of this story appeared in

Volume 89, Issue 5

A novel scanning probe lithography method can simultaneously draw many thousands of patterns with features smaller than 50 nm, according to a study published in Nature by researchers at Northwestern University (DOI: 10.1038/nature09697). The work may lead to versatile and readily implemented procedures for making nanoscale components of electronic and biotechnology devices by providing tools and techniques that are simpler and less expensive than ones in use today.

A number of alternatives to costly commercial lithography techniques have been developed in recent years for patterning applications. Various types of microcontact printing and scanning probe methods, for example, have been demonstrated repeatedly. Yet these methods each exhibit some key drawback, such as depending on relatively complex tools or being limited in resolution, throughput, or breadth of application.

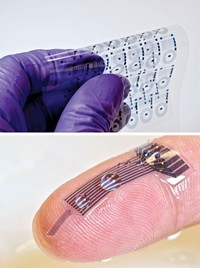

The new technique, which was developed by Northwestern’s Wooyoung Shim, Adam B. Braunschweig, Chad A. Mirkin, and coworkers, sidesteps many of those limitations. Dubbed hard-tip soft-spring lithography, the method is based on a cantilever-free array of pyramid-shaped silicon tips (4,750 in this demonstration) mounted on a compressible elastomeric layer. The tips’ hardness and roughly 20-nm diameter provide high spatial resolution, and the array design lends itself to scale-up and implementation with commercial atomic force microscopes.

The team made the array structures in a layer-by-layer fashion by using standard photolithography, masking, and chemical-etching procedures. In the finished product, the silicon tips rest on a silicon dioxide layer, which in turn is supported on a polymethyldisiloxane-coated glass slide.

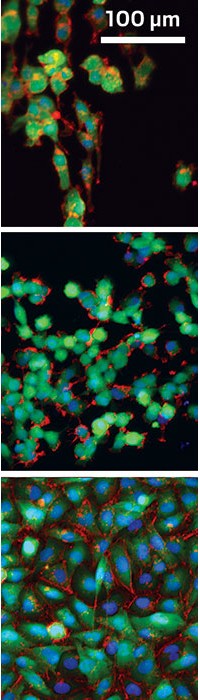

In one demonstration, the group quickly drew roughly 19,000 copies of the pyramid image shown on the U.S. $1.00 bill. The micrometer-sized patterns, which were drawn as bitmap images with 16-mercaptohexadecanoic acid “ink” on a gold surface, consist of closely spaced 40-nm dots. The team also drew patterns with polyethylene glycol on a coated silicon surface and imprinted a polymer film with ordered rows of 40-nm-diameter holes.

By exploiting the springiness of a soft polymer layer, the group has “introduced a clever way of eliminating cantilevers from a scanning probe experiment and, in the process, dramatically decreasing the complexity of the system and the cost of array fabrication,” says Joseph M. DeSimone, a nanopatterning specialist at the University of North Carolina, Chapel Hill.

DeSimone adds that this advance has a good chance of transitioning scanning probe lithography from primarily the domain of academic laboratories to an important production and prototyping tool broadly used across the semiconductor and biotechnology industries.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter