Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

A Plastic That Behaves Like Glass

Malleable material contains esters that swap positions in cross-links when the polymer is heated

by Bethany Halford

December 19, 2011

| A version of this story appeared in

Volume 89, Issue 51

COVER STORY

A Plastic That Behaves Like Glass

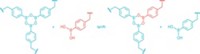

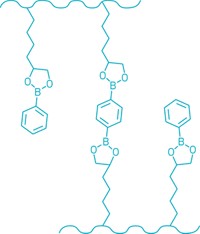

Chemists in France unveiled this year a material that mimics the malleability of glass but retains the toughness and stability of thermoset plastics (C&EN, Nov. 21, page 5; Science, DOI: 10.1126/science.1212648). The polymer could be useful to make parts for the automotive and aerospace industries, among others. “Anywhere you have a complex shape, you can use this material,” said lead researcher Ludwik Leibler of the School of Industrial Physics & Chemistry, in Paris, part of France’s National Center for Scientific Research (CNRS). “It’s much lighter than metal or glass, it’s chemically resistant, and it’s recyclable.” Thermoset plastics, such as Bakelite, are stable to solvents and extreme temperatures. But they must be polymerized in a mold to give them a shape. And once they’ve been polymerized, thermosets can’t be reshaped or reprocessed, either with heat or with solvent. Leibler’s polymer retains the stability of a thermoset even as the material is heated and manipulated like glass into desired shapes. The key to the glassy behavior lies within the polymer’s molecular structure; it has an equal number of ester and alcohol groups. When the material is heated, it transesterifies—that is, its ester cross-links transfer from one region of the polymer to another, with the help of an embedded zinc catalyst. “You exchange links, but you never diminish the chemical bonding” that gives the polymer its strength, Leibler explained. His team has patented the material and hopes to see it commercialized soon. The chemical components, which include a bisphenol A derivative and a mixture of long-chain carboxylic acids, are inexpensive and readily available, Leibler said.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter