Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Peeling Away Nanosheets

Materials Science: Liquid exfoliation enhances materials’ properties

by Bethany Halford

February 7, 2011

| A version of this story appeared in

Volume 89, Issue 6

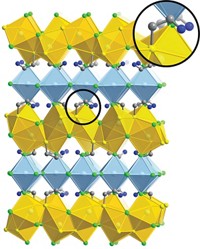

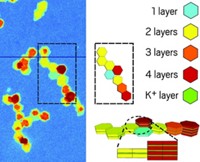

Using a combination of sonication, centrifugation, and judicious solvent selection, scientists have developed a general method for stripping single- and few-layer sheets from stacked substances, such as tungsten disulfide and boron nitride (Science, DOI: 10.1126/science.1194975). The resulting nanosheets have properties distinct from those of the bulk materials and could find applications in electronics and energy storage.

Exfoliating individual sheets away from certain layered compounds enhances the material’s physical properties. Graphene, for example, has remarkable electronic properties when stripped away from bulk graphite. But most exfoliation methods either produce only small amounts of material or are tedious and impractical.

Now, researchers led by Jonathan N. Coleman, of Trinity College Dublin and Valeria Nicolosi, of the University of Oxford, report a simple exfoliation procedure for transition-metal dichalcogenides. The technique works with common solvents, is insensitive to moisture and air, and can be scaled up to give hundreds of grams of exfoliated material.

The researchers first sonicate the material in a solvent that has a surface energy similar to that of the layered material. Suitable solvents, such as N-methylpyrrolidone and isopropyl alcohol, “will generate stable dispersions where solvent-solvent, layer-layer, and solvent-layer interactions are very similar to each other,” Nicolosi explains. Energy from sonication traps the solvent between layers, splitting them apart, she adds. Finally, the dispersions are centrifuged to isolate flakes of the nanosheets, which can then be formed into ultrathin films. The process is so simple, Coleman says, “it can be done in any lab by anyone.”

Yi Lin, a scientist at the National Institute of Aerospace, in Hampton, Va., who recently developed an aqueous procedure for exfoliating boron nitride (J. Phys. Chem. C, DOI: 10.1021/jp110985w), says Coleman and Nicolosi’s approach “enables the ability to evaluate an array of two-dimensional material systems that have exceptionally interesting combinations of properties. Importantly, such solvent-exfoliation methods are essentially impurity-free with neither surfactants nor chemical functionalization involved.”

Lin adds, however, “The ultimate challenge is to obtain large quantities of nanosheets with only a single layer, where the science may become even more fascinating.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter