Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Business

Retooling A Bacterial Biofuel Factory

ACS Meeting News: Gene swaps tweak kinetics, equilibrium to increase output

by Carmen Drahl

March 31, 2011

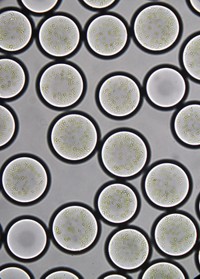

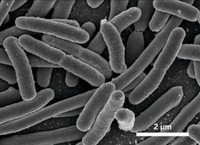

In a step toward more efficient biofuel production, two independent teams have improved on past efforts to engineer Escherichia coli so the microbe produces higher outputs of n-butanol than ever before—more than 30 times as much as prior engineered strains. The studies were presented on Wednesday at multiple divisional meetings of the ACS national meeting in Anaheim.

Several chemical companies are pursuing butanol as a biobased fuel source. Most vehicles can run on a blend of butanol and petroleum-based gasoline. Rising gas prices and modern biotechnology have revived interest in an early-20th-century butanol fermentation process. That method used a slow-growing bacterium called Clostridium acetobutylicum and was best known for producing butanol as fuel for World War II-era planes.

Researchers previously transferred Clostridium's genes for butanol synthesis into the workhorse bacterium E. coli, but butanol output has been modest.

In the Division of Organic Chemistry, graduate student Brooks B. Bond-Watts presented how he, Robert J. Bellerose, and chemist Michelle C. Y. Chang of the University of California, Berkeley, used a kinetic trick to trap a butanol synthesis reaction in the forward direction (Nat. Chem. Biol., DOI: 10.1038/nchembio.537). In the Division of Biochemical Technology, graduate student Claire R. Shen described how she, James C. Liao, and colleagues at UCLA also pushed microbial-butanol-making reactions' equilibrium forward by interfering with competing pathways (Appl. Environ. Microbiol., DOI: 10.1128/AEM.03034-10).

The native Clostridium pathway isn't optimized to make the most butanol possible, so it can be tweaked to increase output, says Chang, who also presented her team's work in the Division of Biological Chemistry. The pathway includes an enzyme that catalyzes a reversible double-bond reduction. To boost butanol output in E. coli, her team replaced the gene encoding this Clostridium enzyme with another gene, called ter, encoding trans-enoyl-coenzyme A reductase, which makes the reduction irreversible. This irreversibility prevents chemical intermediates from being diverted backward, away from butanol.

Different enzymes change reactions' activation energies—that is, the amount of energy input required to make a reaction go—by different amounts, Chang explained. Using the Ter enzyme makes it nearly impossible for the double-bond reduction to go in reverse because it eliminates an intermediate state. Energetically, the new setup means that going backward would require a far higher energy input than before, Chang explained. As a result, Chang's flasks of E. coli produced nearly 5 g of n-butanol per liter—about 10 times more than previous engineered E. coli but not yet comparable to levels from Clostridium.

Chang's work "serves as a reminder that there is a lot more to engineering a functional and well-performing pathway than just stitching the pathway genes together," comments Massachusetts Institute of Technology metabolic engineer Gregory N. Stephanopoulos.

At UCLA, Shen, Liao, and colleagues coupled the irreversible Ter reaction to two driving forces based on the enzyme cofactor NADH and acetyl coenzyme A. Clostridium's butanol biosynthesis requires a pool of acetyl coenzyme A as a starting material and a pool of NADH to drive various transformations, Liao explained. Bacteria produce both of these compounds, but other reactions consume them immediately, Liao said. So his team knocked out enzymes that divert the two feedstocks elsewhere and overexpressed a gene that produces NADH, thereby boosting E. coli's butanol production. The result was a yield of 15 g/L in flasks and 30 g/L in a fermentor, comparable to Clostridium's output.

"Everybody knows how to push equilibrium" in principle, Liao said. "But in this case it is surprisingly effective."

Liao's team used a 1-L bioreactor for their fermentation, a much smaller scale than would be used industrially. Economic factors play a role in whether butanol will become a viable fuel, Liao said. "But certainly our next step is to scale up."

Until now, butanol production levels from engineered microbes haven't been encouraging for industrial use, said MIT chemical engineer Kristala Jones Prather, who attended the meeting. The new work presented at the ACS meeting, she said, suggests that the approach has promise after all.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter