Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy

Designing Lithium-Ion Batteries To Last

Cathode Materials: Encasing sulfur in nanofibers could help high-energy batteries survive repeated recharging

by Katherine Bourzac

October 7, 2011

A new electrode design for lithium-ion batteries stores twice as much energy as those found in today’s portable electronics. It also doesn’t degrade when discharged and recharged (Nano Lett., DOI: 10.1021/nl2027684). The design may help battery manufacturers overcome problems that have kept a promising technology from reaching the market.

As lithium-ion batteries’ storage capacity increases, electric cars and smartphones both function longer without needing to recharge. But researchers have had difficulty making high-energy batteries that can last through repeated recharging. The key is designing electrodes that can store large amounts of energy and don’t degrade during the battery’s lifetime. Researchers have made commercially viable, high-energy anodes, but the cathode has remained a major challenge, says Yi Cui, associate professor of materials science and engineering at Stanford University.

One of the most promising cathode materials is sulfur, which can store a lot of energy, and is abundant and nontoxic, Cui says. But despite fifteen years of work, lithium-ion batteries that use sulfur cathodes have had limited commercial success. For example, Sion Power sells such batteries to the military for uses such as powering long-distance unmanned planes. But because lithium-ion batteries with sulfur cathodes can only recharge about 50 times, Cui says, they haven’t reached consumers.

The problem, Cui explains, is that structural and chemical instability in the cathode cause the batteries to fail. As the batteries discharge and recharge, the cathode expands and contracts as sulfur takes up and releases lithium from the battery’s electrolyte solution. This physical stress leads the cathode to crack. Also, the cathode’s sulfur reacts to produce lithium polysulfides that dissolve into the electrolyte, taking away active material from the cathode. The polysulfides also can enter and react with the anode, damaging it.

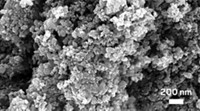

Cui and his colleagues realized that they needed to contain the cathode’s sulfur. To do so, Cui’s group built carbon-nanofiber bundles and filled them nearly to the top with sulfur.

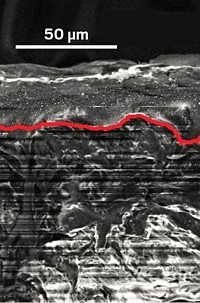

The researchers used a templating technique, growing the carbon nanofibers on an aluminum-oxide membrane riddled with 60-µm-deep holes that were about 200 nm in diameter. They then filled the nanotube bundles with sulfur before etching away the template.

While charging, the sulfur in Cui’s cathode can expand into the empty space inside the fibers. The carbon tubes also prevent the sulfur from reacting with the battery’s lithium: They expose only a very small area of sulfur to the electrolyte. When compared to lithium-ion batteries in today’s portable electronics, batteries with the new sulfur electrodes store twice as much energy. This storage capacity remains stable after 150 charge cycles, the researchers report.

Linda Nazar, professor of chemistry at the University of Waterloo, says that the principles behind the design are promising, but that the production method may not be practical for manufacturers.

Nonetheless, the Stanford group is in discussions with Amprius, a start-up company that makes high-energy silicon anodes, about producing a battery with both electrode types. Cui, who co-founded the company, says that such a battery could store four times as much energy as those on the market.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter