Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Polymer Sheets Shape Up

ACS Meeting News: Lithographic patterning technique dictates 3-D forms that polymer gel films can adopt when hydrated

by Lauren K. Wolf

April 2, 2012

| A version of this story appeared in

Volume 90, Issue 14

By mimicking a technique typically used by news media to print pages in color, researchers at the University of Massachusetts, Amherst, have developed a way of lithographically patterning flat polymer gel sheets so they eventually acquire three-dimensional shapes (Science, DOI: 10.1126/science.1215309).

In addition to helping scientists understand how natural soft structures such as flower petals and embryos take shape, the technique could be used to make polymer actuators. These devices move in response to external stimuli, such as temperature change. Polymer actuators might eventually be used in drug delivery systems, sensors, and engineered-tissue scaffolds.

There’s been a long history of scientists trying to use polymer gels as actuators, said Ryan C. Hayward, who presented the research in the Division of Polymeric Materials: Science & Engineering at last week’s American Chemical Society national meeting in San Diego. In particular, Eran Sharon, a physicist at Hebrew University of Jerusalem, took some promising steps in 2007 toward polymer actuators that Hayward said were the inspiration for this new gel-printing process.

Specifically, Sharon and his group showed that flat polymer disks made of N-isopropylacrylamide (NIPAM) gel could be converted into 3-D forms (Science, DOI: 10.1126/science.1135994). But the study was a proof of concept, Sharon told C&EN, so the method his team used to fabricate the gel sheets—injection of graded amounts of NIPAM monomer into a mold with a cross-linker and catalyst—was primitive. The work by Hayward and collaborator Christian D. Santangelo “is a significant step forward,” Sharon added. “It makes the extremely important jump from the demonstration stage to the development of a reliable, accurate, and flexible technique.”

To fabricate their polymer actuators, Hayward, Santangelo, and coworkers adopted halftone printing, a method in which dots of just a few colors of ink are mixed to make a broad range of hues and shades. “It’s very expensive to print something in shades of color,” says Hayward, a polymer scientist. So newspapers and other print media save on ink by blending dots of a limited color palette to make new tones. The news outlets also vary the size of colored dots to adjust shade. For instance, a field of small blue dots on a white background appears light blue in shade, whereas large blue dots look dark blue from a distance.

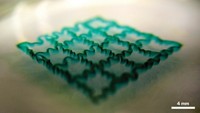

The UMass Amherst group used this trick to pattern polymer sheets. But rather than controlling color and shade with the size and spacing of the dots, the team used dots to dictate the swelling and curvature of the gels.

After generating a copolymer sheet made of NIPAM and benzophenone acrylamide, a light-activated cross-linker, Hayward and Santangelo’s group patterned the gel with two lithographic masks. The researchers exposed the sheet to a low dose of ultraviolet light through the first mask to define the sheet’s boundaries. Then they shined high doses of UV light through the circular dots of a second mask.

When hydrated, a polymer gel sheet made this way doesn’t swell much in the dotted areas of highly cross-linked material, Hayward said. But it does swell everywhere else, buckling into a designated shape.

Santangelo, a physicist, and postdoc James A. Hanna predicted the shapes the sheets would take—saddles, cones, and spherelike structures—by solving a set of differential equations. Even more important, Santangelo said, by using these calculations, “we can start with a shape and work out exactly what swelling pattern would be needed to make it” from a polymer sheet.

This method could help answer some basic questions, Hayward said. “If you look at the mechanisms by which leaves and flower petals grow, it has to do with a very thin sheet of material in which there is differential expansion,” he added. “We’re interested in that shape selection process.”

The researchers also showed that the polymer gel sheets could be interconverted between their flattened-out structures and their 3-D forms by adjusting temperature. At room temperature, hydrated gel sheets retained their 3-D shapes, but at an elevated temperature of 49 °C, the sheets dehydrated and became flat.

Given that body temperatures around 37 °C would thus partially unfold the gel shapes, Hayward recognized that the NI PAM-benzophenone gels, in their current form, would not hold up in most biomedical applications. But, he added, the sheets’ chemistry could be changed to fix that problem.

“The principles involved are universal,” Santangelo added. “If it’s just a matter of finding the right material, then eventually someone will do it.”

Despite that limitation, Adam W. Feinberg, a biomedical engineer at Carnegie Mellon University, thinks the new technology has great potential in tissue engineering. In that field, “it is straightforward to create sheets of cells but not to organize the cells into 3-D tissues.” The polymer gel sheets could one day be primitive templates for engineered organs, he added.

Echoing that forward-looking sentiment, Hebrew University’s Sharon said: “Now that there is such an attractive technique” for making these polymer actuators, “they will enter into the engineering world. And who can tell what the creative minds in that field will do with them?” ◾

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter