Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

ACS News

In Charge: DOD’s Chief Technology Officer Lays Out Plan For The Future

by Andrea Widener

August 6, 2012

| A version of this story appeared in

Volume 90, Issue 32

Zachary J. Lemnios, assistant secretary of defense for research and engineering, oversees the Department of Defense’s vast science and technology enterprise. This includes 67 labs, 60,000 employees, and a $74.5 billion 2012 budget.

COVER STORY

In Charge: DOD’s Chief Technology Officer Lays Out Plan For The Future

An electrical engineer, Lemnios came to DOD in June 2009 after serving as chief technology officer at Massachusetts Institute of Technology’s Lincoln Laboratory, a defense research center. He was also a program manager at the Defense Advanced Research Projects Agency (DARPA), DOD’s high-risk, high-reward research program.

One of the biggest challenges facing Lemnios is ensuring that DOD’s R&D portfolio meets the rapidly changing needs of the military, which is moving to a smaller force working in different types of conflicts in new areas of the world.

C&EN sat down with the assistant secretary recently to discuss R&D at DOD.

What are DOD’s major research priorities?

The department is going through a pivot in its strategy, especially the movement of troops to the Asia-Pacific region and the Middle East, coupled with the enormous budget pressure that we all see. We will need new technologies to face some very challenging threats, which drives us to really push innovation, push advanced technology.

We have identified a set of science and technology priorities to guide our research and engineering enterprise. We looked at the department’s key missions and where we need technology to support those missions.

In the basic science area, we identified the areas that are emerging so rapidly that the department really has to have a finger on the pulse, areas that we need to keep track of what is going on and maybe shape the early investment. These included areas like synthetic biology, quantum information sciences/quantum computing, cognitive neurosciences.

How does chemistry fit into the agency’s priorities?

Chemistry today is more interdisciplinary than it was when I was in graduate school. You have people thinking about how to take an idea and work with an engineer to implement it or to scale a material so it could be used to build a [Boeing] 787. It is a discipline where the modeling and simulations tools have advanced so that more people can design molecules and build them. We have leveraged the heck out of those changes, trying to build bridges with industry and academia. The areas that could lead to big changes for us are advanced materials, advanced fuels, and polymer chemistry.

How do you balance early research with DOD’s immediate needs?

That is the challenge. In the priority areas we’ve identified, we need to make sure that we have a solid understanding of the underlying physics and chemistry so that we can actually go from a basic research concept to something that has more engineering to actually utilizing those concepts. And every day we look for that bright researcher who has an idea that we should be investing in.

Other bets are on what our warfighters need on an immediate basis, and we try to drag those concepts out of our research community, out of academia, out of industry, and rapidly transition those to the field. A great example of chemistry that has made a difference for our warfighter is the move from titanium plates to ceramic body armor. Ceramic is a much lighter weight armor and just as effective.

How would you describe DOD’s relationship with universities?

I think it’s terrific. We are fostering innovation and trying to identify the best and the brightest at universities. We want to have those professors and those students work on the nation’s most challenging national security issues and transition those discoveries to the private sector.

Our National Security Science & Engineering Faculty Fellowship program targets rising stars in academia and tries to give them some support and get the best ideas out of those labs. The Scholarship-for-Service program provides a stipend to undergraduate and graduate students, and they have the opportunity to work in one of our laboratories. Many have become employees of the department after their experience.

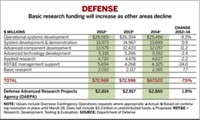

How are you dealing with declining budgets?

We are doing pretty well. The defense secretary understands the value of our science and technology portfolio. The budget request that is on Capitol Hill right now is comparable to what it was last year, a modest decline but not terribly significant. That is because we are able to make a case that that investment has a targeted and clear application to the warfighter five to 10 years from now. If we don’t make that investment now, we take those options off the table.

Will the looming government-wide budget cuts impact DOD’s R&D?

The word that everyone uses is devastation, and it would be. It is counterproductive; it is disruptive. It would particularly hurt the small-business community, and my sense is it would hurt academia as well. Our plan is that Congress will resolve it, as they should.

What is your message to the chemistry community?

We are at a time when we really need the help of the chemistry community. High-efficiency batteries, lightweight materials, engineered materials, and new manufacturing concepts are all important—and all involve chemistry. We also have got to be cognizant of how we develop new technologies and do that development within a cost structure that makes sense. So technologies that can reduce the cost of our operations would be a big deal.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter