Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Artemisinin Goes With the Flow

Pharmaceuticals: Continuous-flow synthesis produces antimalarial at low cost

by Bethany Halford

January 23, 2012

| A version of this story appeared in

Volume 90, Issue 4

Gaining access to the antimalarial compound artemisinin could become easier and less expensive, thanks to a continuous-flow synthetic procedure developed by researchers in Germany (Angew. Chem. Int. Ed., DOI: 10.1002/anie.201107446). The new procedure improves upon current synthetic approaches, according to its inventors, and offers a more reliable route to the compound than extraction from its natural source, the plant Artemisia annua.

Artemisinin is currently the most effective treatment in the fight against multi-drug-resistant forms of malaria, and the World Health Organization recommends artemisinin-based combination therapies as first-line drugs. Although artemisinin can be extracted from A. annua, the plant is seasonal, making the supply unreliable and the cost volatile.

Scientists previously devised a semisynthetic route to artemisinin based on the intermediate artemisinic acid—a compound that can be produced by specially engineered yeast. That technology was invented by a group led by Jay D. Keasling, a professor at the University of California, Berkeley, and was developed commercially by the biotech firm Amyris. Amyris has licensed the technology to Sanofi with the hope of bringing semisynthetic-artemisinin-based therapies to the market by 2013.

But converting artemisinic acid into artemisinin is no simple task. It involves installing an endoperoxide group and generating three of artemisinin’s rings. Doing this complex chemistry on a scale sufficient to meet the demand of 225 million malaria patients in developing countries presents a formidable challenge.

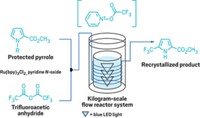

That’s where the work of Peter H. Seeberger and François Lévesque comes in. The researchers, from Germany’s Max Planck Institute for Colloids & Interfaces, have now figured out how to combine three key reactions—photochemically induced oxidation with singlet oxygen, acid-mediated cleavage of an oxygen–oxygen bond, and oxidation with triplet oxygen—into a single continuous-flow process en route to converting artemisinic acid into artemisinin.

One crucial step in the transformation requires photochemical generation of singlet oxygen, which is highly reactive. This reaction is difficult to do in traditional large-scale reactors. Seeberger and Lévesque discovered they could generate singlet oxygen on a relatively large scale in a continuous-flow reactor by simply wrapping the tubing that contains the reactant flow around a cooled mercury lamp (Org. Lett., DOI: 10.1021/ol2017643).

Chemists often avoid singlet oxygen reactions “because of the hazardous batch operating conditions and the potentially explosive hydroperoxides formed,” notes Kevin Booker-Milburn, a continuous-flow chemistry expert at the University of Bristol, in England. “I believe that chemists will now be much more likely to use this reaction under the Seeberger flow conditions since the potentially dangerous peroxides can be dealt with continuously, as they are not ‘stockpiled’ as they would be in a conventional batch process,” he says.

“This eye-catching, technically enabled synthesis will very likely stimulate process chemists to consider new oxidation protocols that they would have traditionally shunned,” Booker-Milburn adds.

At present, Seeberger tells C&EN, the continuous-flow reactor can produce 800 g of artemisinin per day, and he estimates it would take 400 such reactors to make the world’s supply of the drug. “This is just the tip of the iceberg,” Seeberger says. “I believe there are many other drugs that could be made in this way.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter