Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Membrane Unmixes Oil And Water

Hydrophilic-oleophobic combo could clean up oil spills, treat wastewater, purify fuels, separate emulsions

by Stephen K. Ritter

December 24, 2012

| A version of this story appeared in

Volume 90, Issue 52

Even though oil and water don’t mix, when they do come together, as in oil spills, they’re difficult to separate. Researchers at the University of Michigan and the Air Force Research Lab developed a membrane that separates the substances with ease, via gravity filtration. In this clip, watch the membrane in action and learn about the materials it’s made from.

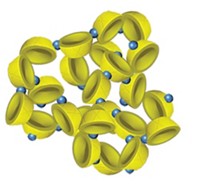

Oil and water usually don’t mix, but when the two end up together, say in an oil spill or in an emulsion, they can be nearly impossible to completely separate. However, by combining a water-loving polymer with an oil-repelling silicon-based material, researchers this year created a new breed of membrane that efficiently separates bulk amounts of any type of oil-water mixture by simple gravity filtration. A team including Arun K. Kota and Anish Tuteja of the University of Michigan and Joseph M. Mabry of the Air Force Research Laboratory devised membranes that sidestep typical membrane limitations—fouling by viscous materials and the energy cost of pumping liquids through the membrane—by dipping polyester fabric or stainless steel mesh in a mixture of cross-linked polyethylene glycol diacrylate, which is hydrophilic, and a fluorinated polyhedral oligomeric silsesquioxane, which is oleophobic (C&EN, Sept. 3, page 9; Nat. Commun., DOI: 10.1038/ncomms2027). When an oil-water mixture or emulsion is poured onto one of the membranes, microcrystalline regions reconfigure to form a smooth, noncrystalline surface that allows the polymer to hydrogen bond with water. Water then flows unimpeded through the membrane, which holds back the oil and is resistant to fouling. The researchers envision the membranes being used not only to clean up oil spills but also to treat wastewater, purify fuels, and separate emulsions used in manufacturing processes. Since the discovery was announced in August, Tuteja says the research team has been approached by three dozen companies with interest in buying membranes or licensing the technology.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter