Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Analytical Chemistry

Large-Scale Production Of Nanosensors

Nanofabrication: To spot gas at concentrations of parts per billion, researchers make arrays of millions of nanoelectromechanical chemical sensors

by Katherine Bourzac

February 10, 2012

For the first time, researchers have made arrays of nanoelectromechanical sensors on a large scale in a semiconductor fabrication facility (Nano Lett., DOI: 10.1021/nl2037479). They say this work demonstrates that these devices, which can detect chemicals at parts-per-billion concentrations, could lead to a gas chromatograph/mass spectrometer on a chip.

The nanoelectromechanical system, or NEMS, sensors are tiny silicon cantilevers, each just 800 nm wide and 2 µm long, that resemble diving boards. When a molecule lands on a sensor, the molecule decreases the lever’s vibrational frequency. As it vibrates less, the stress on the underlying silicon structure changes, causing its electrical resistance to change through a physical effect called piezoresistance. Researchers can easily detect these fluctuations.

Michael Roukes’ group at the California Institute of Technologypreviously built NEMS devices that could detect gases at levels of parts per billion or identify molecules by their molecular weight (Nano Lett., DOI: 10.1021/nl101586s). But for these devices to work, the researchers had to flow large amounts of the chemicals over the sensors, and had to aim the stream directly at the cantilevers, making them impractical for real-world applications, such as detecting chemical weapons. The reason is that single NEMS sensors encounter only a very small cross section of the gas or liquid they’re immersed in.

The Caltech group thought that creating dense arrays of millions of sensors would make the devices more practical than their previous designs, which had four to eight sensors. To do so the researchers would have to develop a new fabrication method, because the processes used in Roukes’ lab and elsewhere yield a maximum of about 1,000 sensors at a time.

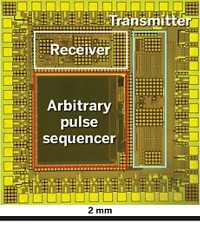

The Caltech group worked with researchers at Minatec, a research center focused on nanotechnology in Grenoble, France, to produce their arrays. They used lithography methods that are standard for mass-producing computer chips. The arrays contained 6 million NEMS sensors per cm2 on silicon wafers. The team designed the connections among sensors to ensure that the devices would work even if some sensors failed or if errors occurred during lithography, which uses equipment that’s not designed to create chips with moving parts.

To test their arrays, the researchers coated the wafer with a polymer that has a high affinity for the chemical warfare agent diisopropyl methylphosphonate. The devices could detect 1 ppb of the gas within two seconds.

The group’s use of large-scale manufacturing techniques to make huge numbers of NEMS sensors indicates that NEMS technology is maturing, says Kamil Ekinci, a mechanical engineer at Boston University, who developed the first NEMS molecular weight sensor with Roukes about a decade ago. The NEMS sensors are not yet as sensitive as conventional analytical technologies such as gas chromatography, he says, but they’re “going in that direction.”

Edward Myers, an engineer in Roukes’ lab, points out that NEMS sensor arrays could offer benefits such as portability and low manufacturing costs, leading to handheld gas chromatogaphs and mass spectrometers. “The hope is that economies of scale will prevail,” he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter