Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy

High-Energy Battery Built To Last

Materials Science: Lithium-sulfur battery electrodes built from smaller sulfur molecules are more stable

by Katherine Bourzac

November 8, 2012

High-energy batteries could increase the distance that electric vehicles can drive and enable portable electronics to run longer without a recharge. Lithium-sulfur batteries are promising because they can store four to five times as much energy as do lithium-ion batteries on the market. But lithium-sulfur batteries are not practical because they rapidly degrade as they charge and discharge. Now Chinese researchers have confined small sulfur molecules in a carbon composite to make lithium-sulfur electrodes that give a steady power output without degrading (J. Am. Chem. Soc., DOI: 10.1021/ja308170k).

Destructive side-reactions eat away at the cathode of lithium-sulfur batteries as they discharge. The cathode contains sulfur in the form S8. During discharge, lithium ions move from the anode into the cathode, reacting with S8 to form a variety of polysulfide compounds. Because many of these polysulfides are soluble in the battery’s electrolyte, the sulfur cathode dissolves during discharge.

Researchers led by chemist Li-Jun Wan, of the Chinese Academy of Sciences, traced these polysulfide problems to S8, one of the many pure elemental forms, or allotropes, of sulfur. Each sulfur allotrope reacts differently with other chemicals, says Yu-Guo Guo, a chemist who collaborated with Wan. The researchers thought that allotropes no larger than S4 would react with lithium to form fewer soluble compounds than larger allotropes do.

Making a cathode based on smaller sulfur allotropes is challenging, Guo says, because they are not as stable as S8 and tend to react with each other to form other allotropes. The team decided to stabilize the smaller allotropes by physically confining the sulfur in the cathode so that the molecules couldn’t form large allotropes.

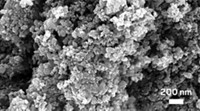

The researchers made a conductive, highly porous matrix of carbon nanotubes to act as the cathode’s backbone, and coated it with microporous carbon, with a pore size of 0.5 nm in diameter. As the researchers heated the matrix and added sulfur, the sulfur diffused into the tiny pores in the carbon coating, and formed allotropes that ranged from S2 to S4. They confirmed the presence of the small allotropes by Raman spectroscopy.

Using their new sulfur cathode, Wan, Guo, and colleagues then built a battery, adding an electrolyte and an anode. The battery worked well after 200 charge-and-discharge cycles and didn’t degrade like typical lithium-sulfide batteries. Rather, the battery steadily discharged at 1.9 V. Guo says the researchers are now working on making cathodes with a higher ratio of sulfur to carbon, which should increase the amount of energy the batteries can store in a given volume. Carbon takes up space but doesn’t add to the battery’s storage capacity.

Yuegang Zhang, a chemist who develops battery materials at the Lawrence Berkeley National Laboratory, says that the new cathode’s 200-cycle lifetime is impressive as a first demonstration, but he wants to see more long-term data. To be commercially viable, a battery has to last thousands of charge cycles. “It is still a speculation that sulfur will keep its S2 to S4 form after cycling,” he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter