Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Spinning Superior Nanotube Fibers

Nanotechnology: Carbon-based threads possess remarkable strength and conductivity

by Bethany Halford

January 11, 2013

| A version of this story appeared in

Volume 91, Issue 2

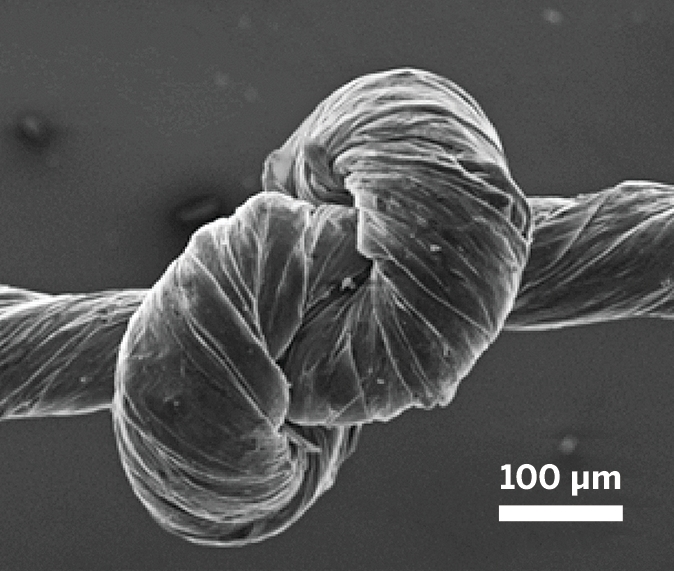

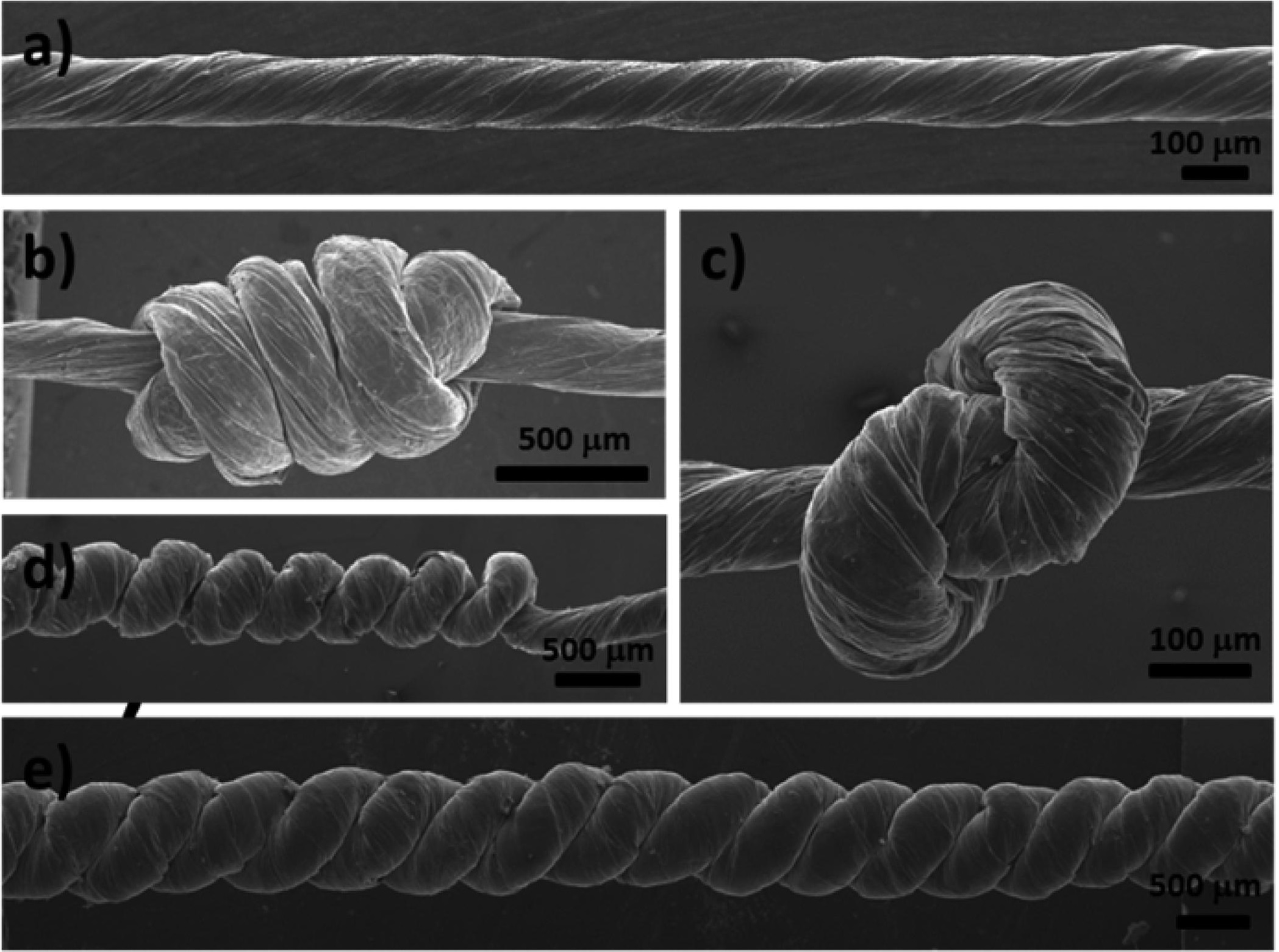

With a process scalable for industry use, carbon nanotubes can now be woven into strong yet whisper-thin threads capable of conducting heat and electricity. These nanotube fibers are likely to have applications in aerospace electronics and could eventually be used in consumer electronics and long-range power transmission.

To date, carbon nanotube fibers have been either directly spun into fibers as they are grown in a solid-state process or wet-spun from solution. The solid-state process leads to high-quality fibers, but it isn’t able to produce them on an industrial scale. Wet-spinning is scalable, but until now properties of the wet-spun fibers have been disappointing.

The wet-spun fibers’ shortcomings seem to be attributable to the short 0.5-μm nanotubes they’re made of. When conducting electricity, losses occur every time electrons jump from tube to tube within a fiber, explains Rice University chemical engineering professor Matteo Pasquali.

If the fibers were made with longer nanotubes, electrons wouldn’t have to make that leap as often. So Pasquali, along with coworkers from Rice, the Dutch firm Teijin Aramid, the U.S. Air Force, and Technion—Israel Institute of Technology, began to look for longer nanotubes that could be dissolved without losing key properties such as high conductivity. They found 5-μm tubes that could be dissolved in chlorosulfonic acid and then extruded into fibers from spinnerettes (Science, DOI: 10.1126/science.1228061).

The resulting fibers are “not quite as strong as Kevlar or carbon fibers, and they’re not quite as conductive as copper, but they’re close. And the combination of properties is unique,” Pasquali says.

“It seemed that polymer-free, wet-spun carbon nanotube fibers would forever have noncompetitive properties because of short nanotube lengths,” comments Ray H. Baughman, a nanotube fiber expert from the University of Texas, Dallas. “Pasquali’s team has now changed the game by showing that 5-μm-long nanotubes can be spun into usefully strong fibers that have truly remarkable per-pound thermal and electrical conductivities that can be increased by doping.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter