Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Through A Window Brightly

Nanotechnology: New material filters out warm, near-infrared light while letting visible light through

by Bethany Halford

August 19, 2013

| A version of this story appeared in

Volume 91, Issue 33

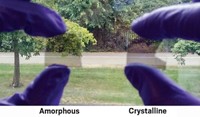

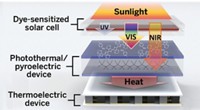

Window shades and blinds could become light-blocking relics, thanks to a nanocomposite material that dramatically darkens or simply filters out warm near-infrared light with the flip of a switch. When incorporated in a window, the new material could boost a building’s energy efficiency by keeping out some of the heat from sunlight without blocking visible light.

The new material is electrochromic, meaning that it switches among different light-blocking states when a voltage is applied. Other smart windows can change from light to dark, such as thermochromics and photochromics, but these are passive and therefore uncontrollable by the user. Electrochromic windows, which can be actively controlled, aren’t new either. But until now no one has been able to block near-IR light without also blocking visible light.

Delia L. Milliron of Lawrence Berkeley National Laboratory’s Molecular Foundry and colleagues accomplished that feat by making an electrochromic material out of tin-doped indium oxide nanocrystals covalently bound to niobium oxide glass (Nature 2013, DOI: 10.1038/nature12398). “Both of those materials are electrochromically active,” Milliron explains. When a voltage is first applied, the nanocrystals charge to produce the near-IR blocking effect. Increasing the voltage makes the niobium oxide glass block visible light.

People had looked at niobium oxide as an electrochromic material before and discarded it partly because it didn’t darken sufficiently, Milliron notes. But by covalently linking the niobium oxide glass to the nanocrystals, Milliron’s team was able to increase its optical contrast to a level five times its original value.

From studying the structure, Milliron and colleagues discovered that the covalent bonds between the nanocrystals and the niobium oxide glass distort the material’s overall structure, creating more open space on the atomic scale and more free volume in the glass. That allows ions to travel more easily through the material, which is why there’s a higher optical contrast when the voltage is increased. “Now that we understand this behavior a little bit, it’s something we’re going to be able to leverage in many other kinds of material systems for different applications,” she says.

The approach offers novel ways to create energy-efficient windows for buildings, says Claes-Gorän Granqvist, an electrochromics expert at Sweden’s Uppsala University and founder of electrochromic window maker ChromoGenics. “However, the technique obviously is a new one, and it may yet be difficult to assess the possibilities for implementation on practical windows.”

Milliron agrees.“This is just an initial demonstration,” she says. The material still needs to be optimized and incorporated into an active window. Still, she’s confident that her team is at a good starting point. Costs should be relatively low, she points out, because the composite is made via a solution-based method. Low production costs are important, she adds, because “this is not an application that can tolerate a high price point.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter