Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Researchers Print MEMS With Metal Inks

Electronics: Ink-jet printing of microelectromechanical devices could cut fabrication costs

by Katherine Bourzac

October 17, 2013

| A version of this story appeared in

Volume 91, Issue 42

Micrometer-scale mechanical and electronic devices called microelectromechanical systems, or MEMS, are used in many electronics devices, such as the motion sensors inside automobile air bags or in smartphones. Now, researchers report the first MEMS device fabricated by ink-jet printing. These printed switches could eventually provide a lower-cost alternative to conventional MEMS sensors and other electronics, the researchers say.

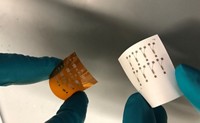

Currently, most MEMS are made from silicon through techniques such as lithography. With ink-jet printing methods, manufacturers could cut costs by continuously fabricating electronics over large surfaces, the way publishers print newspapers, rather than making them in small batches as they do with current methods.

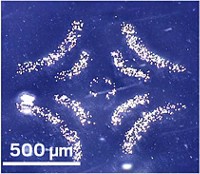

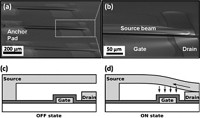

In the new study, Vivek Subramanian and Tsu-Jae King Liu of the University of California, Berkeley, printed 450-µm-long and 2.25-µm-wide MEMS switches using silver nanoparticle inks (Nano Lett. 2013, DOI: 10.1021/nl4028632). The diving-board-like switches each consist of a cantilevered beam anchored to one electrode and hovering over another. When a voltage is applied to the device, the resulting electric field pulls down the free end of the beam so it touches the second electrode, turning on the switch and allowing current to flow across the beam. When the voltage is removed, the beam springs back up, turning off the device.

During fabrication, the team first prints the silver electrodes and then adds a polymer layer to serve as a temporary support as the team constructs the cantilevered beam. Once the beam is set, the team dissolves the polymer with acetone.

The MEMS switches have very strong “on” and “off” states: In the on state, they have low resistances, and in the off state, the resistance is so high that the team couldn’t measure current leakage. Unfortunately, the printed MEMS lack durability. They can switch on and off only 100,000 times before their performance deteriorates.

The Berkeley team has demonstrated a valuable extension of ink-jet printing methods, says Ananth Dodabalapur, an electrical engineer at the University of Texas, Austin.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter