Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

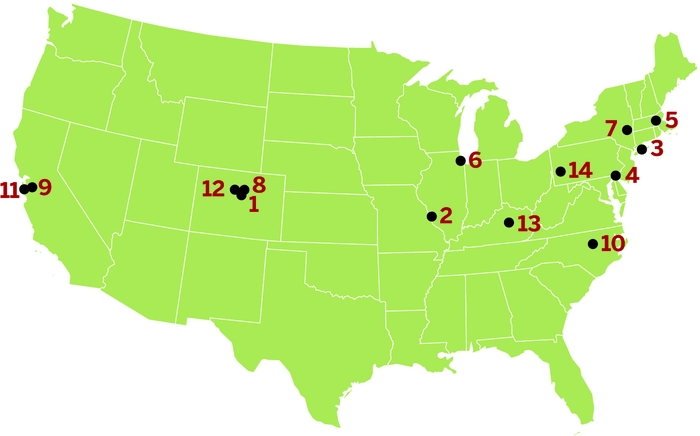

Coast To Coast: DOE makes investments to speed up CO2 capture technologies

by Jeff Johnson

November 25, 2013

| A version of this story appeared in

Volume 91, Issue 47

Postcombustion CO2 capture technologies

1 ADA-ES Highlands Ranch, Colo.

Optimizing the costs of a solid-sorbent-based CO2 capture process through heat integration

$1 million

KEY:

Company

City, State

Project title

DOE investment

2 Akermin

St. Louis

Novel flow sheet for low-energy CO2 capture enabled by biocatalyst delivery system

$3 million

3 Alliant Techsystems

Ronkonkoma, N.Y.

Supersonic postcombustion inertial CO2 extraction system

$3 million

4 American Air Liquide

Newark, Del.

CO2 capture by cold membrane operation with actual power plant flue gas

$4 million

5 Aspen Aerogels

Northborough, Mass.

Bench-scale development & testing of aerogel sorbents for CO2 capture

$3 million

6 Gas Technology Institute

Des Plaines, Ill.

Pilot test of a nanoporous, superhydrophobic membrane contactor process for postcombustion CO2 capture

$10 million

7 GE Global Research

Niskayuna, N.Y.

Pilot-scale silicone process for low-cost CO2 capture

$4.5 million

7 GE Global Research

Niskayuna, N.Y.

Bench-scale process for low-cost CO2 capture using a phase-changing absorbent

$2.4 million

8 Ion Engineering

Boulder, Colo.

Advanced solvent CO2 capture project

$15 million

9 Membrane Technology & Research

Newark, Calif.

Bench-scale development of a hybrid membrane-absorption CO2 capture process

$3 million

10 RTI International

Research Triangle Park, N.C.

Bench-scale development of a nonaqueous solvent CO2 capture process for coal-fired power plants

$2.4 million

11 SRI International

Menlo Park, Calif.

CO2 capture using advanced carbon sorbents at a slipstream scale

$10.5 million

11 SRI International

Menlo Park, Calif.

Development of mixed-salt technology for CO2 capture from coal-fired power plants

$1.7 million

12 TDA Research

Wheat Ridge, Colo.

Sorbent-based postcombustion CO2 slipstream testing

$5 million

13 University of Kentucky Research Foundation

Lexington

Advanced catalytic solvent for low-cost postcombustion CO2 capture in a coal-fired power plant

$3 million

Precombustion CO2 capture technologies

14 Media & Process Technology

Pittsburgh

Robust, energy-efficient dual-stage membrane-based process for enhanced CO2 capture

$2 million

11 SRI International

Menlo Park, Calif.

Development of a precombustion CO2 capture process using high-temperature polybenzimidazole hollow-fiber membranes

$2.3 million

12 TDA Research

Wheat Ridge, Colo.

Pilot testing of a highly efficient precombustion sorbent-based carbon capture system

$8 million

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter