Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Low Temperature Process To Make Crystalline Silicon

Electrochemistry: Researchers hope new electrodeposition method could eventually lead to an energy efficient means to convert silica into silicon

by Prachi Patel

February 5, 2013

CORRECTION: This story was updated on Feb. 15, 2013, to correct a reference to the chemical silicon tetrachloride: The compound is a liquid, not a salt.

Producing pure, crystalline silicon for solar panels and electronics requires heating naturally available silica to 2,000 °C. In hopes of eventually finding a less energy intensive silicon production method, a research team now reports a way to make the vital crystalline material, in small amounts, at 80 °C (J. Am. Chem. Soc., DOI: 10.1021/ja310897r).

To do so, Stephen Maldonado and his colleagues at the University of Michigan, Ann Arbor, tweaked a method called electrodeposition, which researchers normally use to purify metals. Typically, scientists place electrodes into a metal salt solution and pass a current through the liquid. Electrons from an electrode reduce the metal ions and the resulting pure metal deposits on the electrode surface. Because electrodeposition can be economical and scalable, researchers have tried to make crystalline silicon using the process, but such methods still require high temperatures of about 1,000 °C.

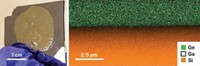

To bring those temperatures down, Maldonado and his colleagues replace one of the conventional solid electrodes used in electrodeposition with a liquid gallium electrode. They layer a silicon tetrachloride solution on top of the pool of gallium and then apply a current. Electrons from the gallium reduce the silicon tetrachloride, and the resulting silicon dissolves into the liquid metal. As the process continues, silicon saturates the liquid and starts to crystallize on the surface of the gallium pool.

The method is currently impractical for large scale production, Maldonado says, because silicon tetrachloride is unstable and is itself made from silicon using an energy-intensive process. But the researchers are trying to modify the technique to work with silica, he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter