Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biological Chemistry

Helping Bacteria Tolerate Biofuels

Protein Engineering: Scientists evolve a bacterial protein pump that pulls butanol out of cells to make microbes into better biofuel factories

by Erika Gebel Berg

September 17, 2013

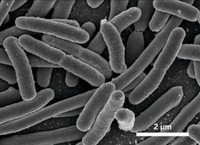

Biologists can engineer microorganisms to make biofuels, such as butanol or octanol, but the cells can’t produce the fuels at industrial scales. One problem is the fuel molecules are toxic to the microbes, killing the organisms before they can produce a high yield. Now, to improve the microbes’ efficiencies, researchers have developed bacteria that expel butanol with a mutant protein pump, helping the microbes to divide faster while swimming among the fuel molecules (ACS Synth. Biol. 2013, DOI: 10.1021/sb400065q).

Microorganisms often use membrane-bound protein pumps to get rid of toxic chemicals that they encounter in their environment. In a previous study, researchers improved biofuel secretion by using directed evolution to enhance the pumping power of an octanol pump usually expressed by Escherichia coli (Biotechnol. Biofuels 2013, DOI: 10.1186/1754-6834-6-81). But such an approach is limiting, says Danielle Tullman-Ercek of the University of California, Berkeley, because it only works if a pump already exists in nature that targets the biofuel of interest.

She wanted to evolve an existing pump to act on any molecule. Tullman-Ercek and her team focused on an E. coli efflux pump called AcrB, which naturally pumps antibiotics out of bacteria, conferring resistance to the compounds. The researchers’ goal was to switch the pump’s preferences from antibiotics to butanol, because there is no known bacterial butanol pump.

Using error-prone polymerase chain reaction, the researchers produced a library of about 50,000 AcrB genes—each with four or five random mutations. They transferred the genes to E. coli and mixed the strains together. The bacteria then battled it out in a liquid culture that was 0.5% butanol. If a bacterium received a gene for a highly efficient butanol pump, it would divide more rapidly than its neighbors, Tullman-Ercek says. “The ones growing better start to dominate the population.”

After three days, the researchers grew the bacteria on plates and picked 30 of the remaining strains for a second round of battle, this time in a 0.7% butanol solution. At the end of that bacterial war, two strains came out on top, each with an improved tolerance to butanol. But the researchers wanted to improve further the protein’s butanol-pumping prowess, so they launched another two-round growth battle, this time starting with random mutagenesis by PCR on the two winning genes. After two more rounds, they had created a strain of bacteria that grows 25% faster in media containing butanol than wild type E. coli can.

To confirm that the mutant AcrB was indeed pumping butanol out of the bacteria, the researchers grew separate cultures of wild-type and mutant bacteria in 0.6% butanol solutions. After an hour, they measured the broths’ butanol concentrations with liquid chromatography and found that the mutant bacteria broth contained 15% more butanol than the wild-type broth did. This suggested that the mutant AcrB kept the butanol outside the bacteria by pumping out molecules that had slipped inside. Tullman-Ercek says she asked her team to run this experiment multiple times because she couldn’t believe the large difference in butanol levels.

Aindrila Mukhopadhyay of the Lawrence Berkeley National Laboratory is impressed by the approach because the mutant pumps not only increase the microbe’s tolerance but also help them export the biofuel product. Exporting the molecules could make it easier to extract biofuel from cultures during industrial production, she says.

Tullman-Ercek’s next step is to check whether the mutant pump can increase the productivity of a bacterial species that naturally synthesizes butanol.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter