Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Printed Electronics Get Mechanical

Electronics: Microelectromechanical devices printed with metal nanoparticles could replace silicon switches in sensors and other electronics

by Katherine Bourzac

October 14, 2013

Inside an iPhone, a microscopic sensor detects the movement of the phone using a microelectromechanical system, or MEMS, device. MEMS combine electronic and mechanical components, which means that they have moving parts and can switch on and off to control the flow of electrical signals.

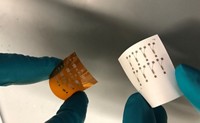

Most high-performance MEMS are made from silicon using high-vacuum, high-temperature processes—the same that are used to make microprocessors. Now, researchers report the first MEMS fabricated using ink-jet printing (Nano Lett. 2013, DOI: 10.1021/nl4028632). These printed switches could eventually provide a low-cost alternative for MEMS sensors, solar-panel controls, and other electronics, the researchers say.

With ink-jet printing methods, manufacturers could continuously fabricate electronics over large surfaces the way publishers print newspapers, rather than making them in batches using complex processes. That should lower manufacturing costs. Some researchers have worked on printing high-performance transistors out of semiconductors, but the resulting devices have had limited success.

Meanwhile, materials scientists have become skilled at printing metals, says Vivek Subramanian, an electrical engineer at the University of California, Berkeley. “Printed metals retain about 70 to 80% of the conductivity and strength of bulk metals,” two important properties for MEMS, he says. So Subramanian, Tsu-Jae King Liu, and their colleagues decided to make printed metal MEMS switches that act like transistors.

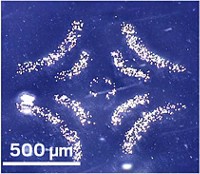

MEMS are challenging to print, with three-dimensional designs and floating parts that have to move. The Berkeley MEMS switch is shaped like a diving board. It consists of a cantilevered beam that is anchored to an electrode on one end. The beam hovers over another electrode called a drain. Next to the drain electrode is a component called a gate. When a voltage is applied to the gate, the resulting electric field attracts the free end of the cantilever, which bends down to touch the drain electrode. This turns the switch on, allowing current to flow across the beam. When the voltage is removed from the gate, the beam springs back up, and the switch turns off.

To make these complicated structures, Subramanian’s group first prints the electrodes and the gate onto a silicon dioxide wafer using silver nanoparticle inks. They then sinter the inks to create silver films. Next the researchers print or spin-coat polymer layers onto the gate and drain. These layers serve as a temporary support as the team prints the beam over the gate and drain using the silver ink. After sintering the beam to make it solid, the researchers dissolve the polymer with acetone, leaving the beam hanging over the drain.

At 450 µm long and 2.25 µm wide, the printed MEMS switches are large compared to printed transistors. But the MEMS switches have very strong “on” and “off” states, Subramanian says. In the on state, printed transistors have resistances high enough to weaken the electronic signal. In the MEMS switches, the on-state resistance is about 10 ohms, compared to 100,000 ohms or greater for a typical printed transistor. Printed transistors also tend to leak current when they’re supposed to be off, which wastes power. The current leakage of the MEMS switches in the off state is so low that it could not be measured, he says.

Unfortunately, the printed MEMS lack durability. They can only switch on and off about 100,000 times before their performance deteriorates. Subramanian thinks he can boost this by a few orders of magnitude by eliminating impurities that weaken the structures.

With this MEMS switch, the researchers have demonstrated a valuable extension of printing methods, says Ananth Dodabalapur, an electrical engineer at the University of Texas, Austin. However, he says these switches cannot compare with transistors because such mechanical switches are too big and too slow to compete with electrical ones. The printed MEMS switches, he says, are more likely to lead to less expensive alternatives to silicon MEMS in sensors and actuators.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter