Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Patent Picks: 3-D Printing

A look at recent patenting activity in 3-D printing in biomedical engineering applications, brought to you by C&EN and CAS

May 22, 2014

| A version of this story appeared in

Volume 92, Issue 21

Three-dimensional printing is taking many fields by storm, and medicine is no different. In 3-D printing, or additive manufacturing, sophisticated printers fabricate objects by laying down successive layers of material. In contrast to traditional machining techniques that achieve the end product by creating expensive molds and then removing material in stages, 3-D printing can produce more complex and detailed shapes.

Jump to Topics:

- A Better Model Of Anatomy

- Custom Joint Implants Stick Tight

- Scaffolds Support Tissue Repair

Spurred by less expensive and more accessible 3-D printers, scientists have begun to experiment with the technology in earnest, according to patenting data from the American Chemical Society’s Chemical Abstracts Service. Biomedical engineers, for example, are using 3-D printers to build better joint replacements and facilitate the repair of broken bones or torn tissues. A few such innovations are highlighted here.

↑ Top

A Better Model Of Anatomy

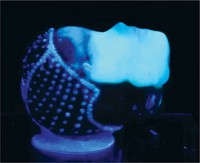

When dentists need to replace a portion of a damaged tooth, they turn to casting techniques. After making an impression of the current tooth and its surroundings, dentists fill the cast with a polymeric material to create a reproduction of the tooth that is then used to design the dental prosthesis. This casting process is time-consuming, and if the patient moves during casting, it can result in an inaccurate reproduction. Researchers from Italy’s Villa Elisa Soverato hospital have invented a 3-D printing method that might make the reproduction process faster and easier. Described in a 2014 patent, the new method involves acquiring a 3-D image of the tooth using panoramic dental X-ray equipment (EP 2682071). The image is used to guide the printing of a 3-D reproduction of the tooth out of a silicon-based polymeric material. Dentists might not be the only ones who benefit: Using colored versions of the polymer, the researchers print 3-D reproductions of body parts in which tissues with different densities are coded by color. Such color-coded copies could guide surgeons in developing operating strategies or medical examiners in conducting virtual autopsies.

↑ Top

Custom Joint Implants Stick Tight

To keep artificial joints in place and stable, manufacturers have begun to try to make implants that mimic bone’s porous quality. Such porous surfaces encourage bone to grow on and into the new joint. Scientists at Warsaw, Ind.-based Biomet Manufacturing take this trend further in a 2014 patent. They describe a method for using 3-D printers to create metal alloy implants that have a porous structure (U.S. 20140025181). The implants’ porous structure can be tailored to mimic the spongelike architecture of bone at the specific anatomic site where the device is to be implanted. Because bone density can vary by patient and by location in the body, the strategy could yield customized joint implants that integrate into neighboring bone.

↑ Top

Scaffolds Support Tissue Repair

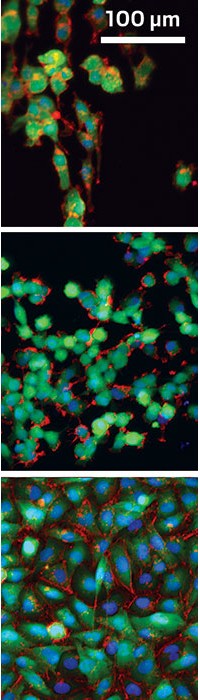

Three-dimensional printers are also being used to create custom biocompatible composite scaffoldlike implants that would support the regrowth or repair of bone and then dissolve away. John L. Ricci and Elizabeth A. Clark of New York University College of Dentistry and their colleagues suggest the scaffolds could be used to treat bone fractures, defects, or deficiencies. In a 2013 patent, they describe a process for printing 3-D scaffolds made from biphasic ceramics composed of hydroxyapatite and tricalcium phosphate (WO 2013181375). The researchers show they can make scaffolds with differentially porous areas that allow for varying degrees of bone and tissue growth. To prevent infections, they infiltrate the pores with calcium sulfate or another soluble filler that can contain antibiotics, anti-inflammatories, growth factors, or other agents. Controlling a scaffold’s pore size can coax the bone to grow in a single direction, improving stability and aiding repair. The scaffolds can be printed with a microporous shell that limits unwanted tissue from growing into the nascent bone.

↑ Top

Jump to Topics:

- A Better Model Of Anatomy

- Custom Joint Implants Stick Tight

- Scaffolds Support Tissue Repair

Patent Picks is a collaborative effort by C&EN and CAS. This feature reports on trends CAS scientists observe from patents in CAS databases. Patents now generate more than 70% of the new substances appearing in the literature.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter