Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy

Safer Salts For Solar-Cell Production

Solar Energy: A magnesium salt may reduce the hazards and costs of making thin-film photovoltaic devices

by Matt Davenport

June 27, 2014

| A version of this story appeared in

Volume 92, Issue 26

Substituting magnesium chloride for toxic cadmium chloride could free cadmium-telluride solar-cell manufacturers from a costly and hazardous process without sacrificing efficiency, according to a new study.

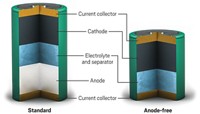

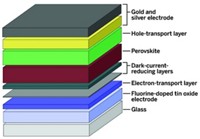

At the heart of a standard CdTe solar cell is a photovoltaic junction formed by the interface between neighboring thin layers of CdS and CdTe. Without processing the layers after deposition, a cell converts incident solar power into electric power with less than 5% efficiency. Manufacturers bump this up to between 10 and 20% using a junction activation step.

For more than two decades, activation has relied on CdCl2, usually deposited as a thin coating on the cell’s CdTe layer. When the cell is heated, chloride diffuses through its stacked structure and reforms the physical and electronic characteristics of the cadmium-containing layers, leaving a more efficient photovoltaic junction.

Jon D. Major and his colleagues at the University of Liverpool, in England, have now succeeded in activating cells using MgCl2 instead of CdCl2 without any loss of efficiency (Nature 2014, DOI: 10.1038/nature13435).

The replacement salt is “completely benign and much lower cost” than CdCl2, Major said at a press conference. On an industrial scale, MgCl2 is available for less than 1% of the price of CdCl2 and requires no specialized waste disposal. “Why it hasn’t been used before, we genuinely don’t know,” he said.

Some aren’t convinced a replacement salt will result in much savings. For example, in a statement released by First Solar, the company that holds the record for CdTe solar-cell efficiency, Chief Technology Officer Raffi Garabedian said that CdCl2 activation “is not a major cost driver in our manufacturing process.”

But smaller start-ups could reap benefits from the research, says Alvin Compaan, professor emeritus of physics at the University of Toledo and cofounder of the thin-film photovoltaic developer Lucintech. Major and coworkers “got some impressive results,” Compaan says. “I think it’s a very important advance.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter