Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Business

LyondellBasell To Build U.S. Propylene Oxide Plant

Shale gas drives investment in the propylene derivative

by Alexander H. Tullo

September 1, 2014

| A version of this story appeared in

Volume 92, Issue 35

In a sign that the shale gas advantage is going beyond the ethylene chain to benefit propylene-derived chemicals as well, LyondellBasell Industries has unveiled plans to build a plant making propylene oxide and the coproduct tert-butyl alcohol (TBA) somewhere on the U.S. Gulf Coast.

The plant will have annual capacity of 900 million lb of propylene oxide and 2 billion lb of TBA and derivatives when it comes onstream in 2019. The firm says the cost of construction should exceed $1 billion.

Propylene oxide is used to make polyols, which are reacted with isocyanates to form polyurethanes. TBA is converted into the fuel additive methyl tert-butyl ether, which is no longer used in the U.S. but still available in other countries.

“The abundant natural gas liquids associated with shale gas make the U.S. Gulf Coast an advantaged feedstock region,” says Pat Quarles, LyondellBasell’s senior vice president of intermediates and derivatives.

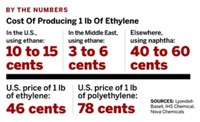

In recent years, the availability of cheap ethane from shale gas has encouraged U.S. petrochemical makers to use less petroleum-derived naphtha as a raw material, explains Chuck Carr, senior director of global olefins at the consulting firm IHS Chemical. This has led to a scarcity of propylene, a coproduct of naphtha cracking.

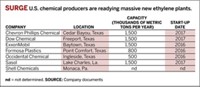

But companies are responding by building plants for on-purpose propylene production via processes such as propane dehydrogenation, or PDH. More than 10 billion lb of such capacity is in the works to come on-line by 2022, according to IHS.

By the time the LyondellBasell plant opens, Carr says, “the PDH that has been announced should be running, and you should have a more rigorous supply of propylene.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter