Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biological Chemistry

Cellulase Research Heats Up

ACS Meeting News: Scientists look to thermophiles for new strategies for biofuel production

by Elizabeth K. Wilson

September 8, 2014

| A version of this story appeared in

Volume 92, Issue 36

Cellulases, enzymes that break down tough biomass, are the workhorses of the nascent biofuel industry.

Currently, a dozen or so commercial cellulases, many produced by fungi, perform the laborious task of chewing fibrous plant waste into sugars that can be turned into ethanol. But the industrial-scale processes used to produce this biofuel are still expensive and inefficient.

“Biofuels haven’t advanced as quickly as many hoped they would,” said Douglas S. Clark, dean of the College of Chemistry and professor of chemical and biomolecular engineering at the University of California, Berkeley. “There haven’t been as many alternative cellulases made available as was projected several years ago.”

Robert Kelly, chemical engineering professor at North Carolina State University, who also studies thermophilic cellulases, echoes the interest in and challenges of finding cellulases that will be useful in industry: “The bottom line is that there are two steps: one is to find interesting enzymes that will break down crystalline cellulose. But the technical reality is that you have to be able to produce really large amounts to be a major player in biofuels.”

Numerous researchers are pursuing the first goal, avidly prospecting for promising cellulases in widely disparate locales, from the guts of bamboo-chewing pandas to geothermal mud pots in Northern California’s Lassen Volcanic National Park.

At a symposium on extreme biochemistry at last month’s American Chemical Society national meeting in San Francisco, Clark brought attendees up-to-date on his team’s recent discoveries of cellulases from extremophiles, and on new ideas for stabilizing cellulases. The symposium was sponsored by the Division of Physical Chemistry.

“Cellulases from thermophiles can exhibit very long shelf lives and half-lives at lower temperatures,” Clark said. “They’re intrinsically very stable enzymes.”

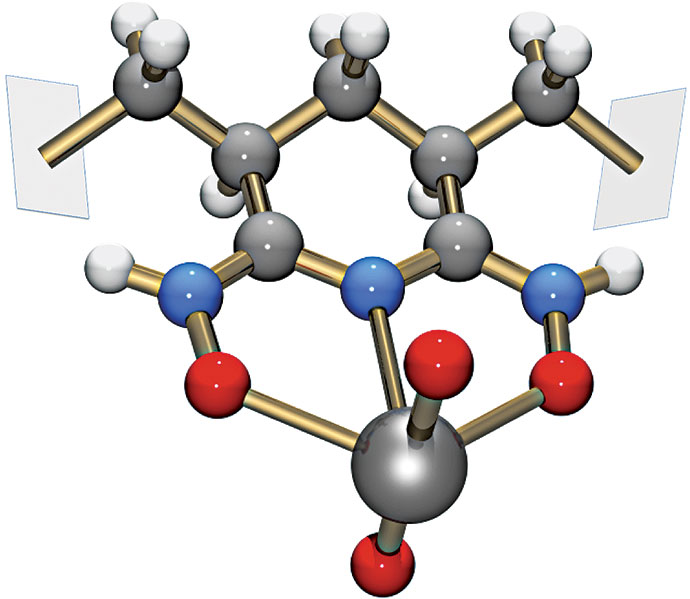

Clark and his collaborators Harvey W. Blanch, also at UC Berkeley, and Frank T. Robb at the University of Maryland made headlines in 2011 when they discovered a species of archaea in hot springs near Gerlach, Nev. The archaeon produced a cellulase, which they call EBI-244, that can withstand temperatures of more than 100 °C (Nature 2011, DOI: 10.1038/ncomms1373).

Current commercial cellulases are frequently obtained from fungi, because fungi can produce cellulases in large quantities. In particular, an endoglucanase known as EG1, produced by the fungus Trichoderma reesei, is used commercially.

However, cellulases from fungi generally tolerate temperatures only up to around 50 °C, much less than the cellulases from archaea. Archaeal cellulases can also tolerate more acidic environments than can those from fungi.

The biofuel industry would welcome cellulases that are heat- and acid-loving because the enzymes would be able to better withstand some of the harsh pretreatment conditions in the biofuel-producing process. In addition, conducting the processes at higher temperatures reduces the risk of bacterial contamination.

Recently, the Berkeley and Maryland team bested their 2011 cellulase discovery, Clark said at the meeting. On an expedition to Lassen Park’s famous geothermal hot spot, Devil’s Kitchen, they found archaea that produced a cellulase that not only remains active up to 100 °C but also at an extremely acidic pH of 2.

“It’s the most hyperthermophilic, acidophilic cellulase yet discovered,” Clark said at the meeting.

Industry watchers are noting these new discoveries. “There’s been hope for some time that the archaea might hold many more pleasant surprises for intrepid researchers,” says Jim Lane, editor and publisher of the online newsletter Biofuels Digest. “And it looks like that hope was not unfounded.”

Clark’s lab is also trying to address another general problem with the industrial-scale use of cellulases: They don’t last very long at temperatures above their comfort zone. After a few hours, they denature, and a new supply must be provided.

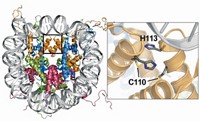

Clark’s group has recently applied their research on a stabilizing chaperone protein they discovered in a deep-sea vent archaeon, known as γ-prefoldin, to the problem of cellulase stability, he said at the meeting.

The γ-prefoldin assembles into long, stable filaments that reduce the inactivation of other archaeal proteins at high temperatures, he said. “We thought it could be interesting to see if the γ-prefoldin stabilizes cellulases,” he said.

They’ve tested it on a fungal cellulase. Preliminary results suggest that the prefoldin increases the half-life of the cellulase at 70 °C from 4.7 hours to 6.5 hours, Clark reported at the meeting.

With the promise of extremophilic enzymes, however, still comes the hurdle of producing industrial-scale quantities. Clark told C&EN, “This chaperone could be a viable method for stabilizing cellulases under operating conditions—providing you could generate enough of it.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter