Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Cleaning Indoor Air: Alternatives To Precious-Metal Catalysts

Researchers are working on low-cost alternatives that can efficiently scrub harmful molecules from the air

by Mitch Jacoby

November 3, 2014

| A version of this story appeared in

Volume 92, Issue 44

Designed by Precision Combustion for use aboard the International Space Station, this compact air purification device features a novel metal mesh substrate (exposed, top) for contaminant adsorption and oxidation.

Designed by Precision Combustion for use aboard the International Space Station, this compact air purification device features a novel metal mesh substrate (exposed, top) for contaminant adsorption and oxidation.

As temperatures dip and leaves change color every fall, automobile showrooms fill up with the latest models. With those shiny new cars comes the unmistakable, seductive scent known simply as “new car smell.”

The volatile organic compounds (VOCs) responsible for the luxury-linked fragrance—benzene, styrene, aldehydes, ketones, and the like—dissipate quickly from a car’s cabin as windows and doors are opened and air circulates over time. So VOCs emanating from an automobile’s plastic surfaces and carpeting pose little risk to human health and are typically not filtered from the air.

Emissions cocktails present inside more stagnant spaces—homes, office buildings, even spacecraft—have the potential to more seriously affect a person’s health. That risk is prompting researchers to develop methods for ridding indoor air of pollutants by converting them catalytically to harmless compounds.

Traditionally, catalytically active precious metals such as platinum and palladium have been used to scrub air by oxidizing VOCs and other gaseous pollutants to innocuous products. But because of the high cost and limited availability of the platinum-group metals, scientists are now searching for low-cost alternatives. These researchers are developing substitutes based primarily on transition-metal oxides. And they’re exploring methods for enhancing the materials’ catalytic activity and longevity by controlling the particles’ microscopic structures and dispersing the particles on high-performance supports.

“Even at trace levels, prolonged exposure to persistent organic compounds can adversely affect human health,” says Taicheng An, a professor at China’s Guangzhou Institute of Geochemistry and a specialist in catalytic VOC abatement.

The ill effects, which can include breathing difficulty, flu-like symptoms, and eye and throat irritation, are sometimes referred to collectively as “sick building syndrome.” Public awareness of this condition climbed sharply after Hurricane Katrina, which bombarded the southern U.S. in 2005 and led thousands of people to move into trailer homes supplied by the U.S. Federal Emergency Management Agency (FEMA). Officials blamed long-term outgassing of formaldehyde from construction materials in the FEMA trailers for the health problems widely reported by trailer residents.

Incidents such as this one have led researchers to be on the lookout for gaseous pollutants even when their effects are subtle or not yet known. For example, a 2012 study led by scientists at Lawrence Berkeley National Laboratory found that not only can low-levels of VOCs be harmful, but even elevated CO2 levels can have a detrimental effect. At 1000 ppm or higher, which is easily reached in crowded classrooms and meeting rooms, people’s mental acuity and decision-making abilities suffered. (Environ. Health Perspect. 2012, DOI: 10.1289/ehp.1104789).

More recently, researchers at Advocate Lutheran General Hospital, in Park Ridge, Ill., determined that standard plastic medical equipment used in incubators for preterm infants, a group of fragile patients particularly susceptible to breathing difficulties, caused levels of cyclohexanone inside the enclosures to rise sharply (J. Perinatol. 2014, DOI: 10.1038/jp.2014.65).

Sometimes, as in the case of the incubators, VOC levels in indoor air can be reduced simply by opening a window or turning on a fan. But that isn’t always an option. “You can’t get fresh air in space, for example,” says Jeffrey G. Weissman, manager of catalyst development at Precision Combustion in North Haven, Conn. Outer space is foremost in Weissman’s mind because he and his team have developed cabin-air cleaning devices for the International Space Station.

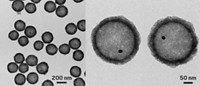

At the heart of these devices lies a catalyst support known as a microlith that’s composed of multiple layers of metal mesh similar to a window screen. In contrast, traditional catalyst supports, such as the ones in automobile catalytic converters, are large ceramic bricks (monoliths) with long, narrow channels in which catalytic reactions occur.

As a result of the microlith’s metal nature and mesh structure, it has greater surface area and is free from the usual heat- and mass-transport limitations that plague ceramic monoliths. Gases, including pollutants, flow more freely through the metal microlith, which can be heated with relatively little energy to initiate catalytic oxidation compared with its ceramic counterpart. The upshot is that for VOC cleanup, microlith oxidizers can be far more compact, lightweight, and fast-acting, regardless of the catalyst they support.

Weissman notes that Precision Combustion’s microlith oxidizers performed admirably in trace-level VOC oxidation tests on alcohols, acetone, toluene, and other compounds. And over the course of 16,000 hours of durability testing, the devices continued to oxidize methane with no decrease in activity.

Now the company is using its microliths to explore low-temperature photocatalytic oxidation. Compared with heat-driven catalysis, photocatalysis uses less energy and may avoid harmful by-products formed by heat-induced side reactions. In tests of ethanol oxidation using ultraviolet light and TiO2-coated microliths, Weissman and coworkers found that ethanol and acetaldehyde, a partial oxidation product, fell below the team’s detection limit (roughly 15 ppm).

Meanwhile, in Guangzhou, An and coworkers are also studying photocatalytic VOC abatement with TiO2. The researchers recently devised a procedure for synthesizing TiO2 crystals in which they tune the amount of NH4F, which reacts with titanium precursors, to expose the most catalytically active TiO2 crystal facets. This structural manipulation maximizes gas-phase styrene oxidation (Catal. Today 2014, DOI: 10.1016/j.cattod.2013.10.073).

Styrene is a common low-level indoor air pollutant found in residential and commercial buildings. It is emitted from various building materials and adhesives and can be present in high levels in plastics factories that have poor ventilation.

The Guangzhou team has also begun investigating the benefits of combining photo- and thermostimulated catalysis. The researchers are using low-cost lanthanum perovskite compounds of the type LaBO3 in which B represents a transition metal. They find that for oxidizing styrene, LaMnO3, LaNiO3, and LaFeO3 are more active than other compounds and that combining photo- and thermocatalysis is more effective than either method alone.

Richard Q. Long can’t share the exact formula of his catalysts, but he and a team of coworkers are developing inexpensive yet highly active core-shell-type catalysts that may be useful in scrubbing air in bakeries and other indoor work spaces. Long, a research scientist at catalyst and fuel-cell manufacturer NexTech Materials, near Columbus, Ohio, describes the materials as mixed transition-metal oxide composites consisting of a micrometer-sized core particle surrounded by a foamlike shell of porous nanoparticles. Core and shell have distinct compositions, he says.

Tests show that the composites oxidize VOCs, including propane, butene, and toluene, to CO2 and water more completely and at lower temperatures than platinum and palladium reference catalysts. Long’s studies also show that the oxides are stable. Their activity remained constant throughout 860 hours of testing. In addition, they tolerate common VOC impurities such as silicon and phosphorus better than precious-metal catalysts.

At Dalian University of Technology, in China, Chuan Shi also takes a two-is-better-than-one approach to low-cost VOC catalysis for purifying air in office buildings, homes, and other indoor spaces. But rather than blending particles of two sizes, Shi makes Co-Mn oxide catalysts with two functions: storage and oxidation.

By using KIT-6, a porous form of silica, as a template that guides structure formation, Shi and coworkers are able to prepare a three-dimensionally ordered porous Co-Mn oxide material. The templated form of the oxide outperforms the standard untemplated form as a formaldehyde storage-oxidation cycling catalyst, Shi says.

During one portion of the cycle, at room temperature, the catalyst partially oxidizes formaldehyde and traps it on the oxide surface. Later, when the catalyst needs to be purged, the scientists raise its temperature briefly, which oxidizes the formaldehyde intermediate to CO2 and water. Those species desorb from the surface, thereby regenerating the catalyst. The key idea of this storage-oxidation catalyst is that the extended periods of room-temperature service enhance the catalyst’s capacity for trapping and storing VOCs and extend its overall lifetime (Catal. Commun. 2013, DOI: 10.1016/j.catcom.2013.03.007).

MnO2 is yet another example of an abundant low-cost material that functions well as a VOC combustion catalyst. Studies by Eric M. Gaigneaux, Víctor G. Baldovino-Medrano, and coworkers at Catholic University of Leuven, in Belgium, show that MnO2 fares well compared with precious-metal reference catalysts when it comes to oxidizing numerous VOCs, including n-hexane, methanethiol, and trimethylamine. The researchers are now studying how various aspects of catalyst manufacturing might affect MnO2’s performance in commercial chemical reactors.

Judging by recent studies, there are several promising precious-metal-free options for ridding confined spaces of harmful pollutants. With continued progress, some of them might even be commercialized sometime down the road—just in time to scrub the air on private spacecraft heading for Mars.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter