Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Cheap Templates For Solar Cells Now On Blu-Ray

Nanofabrication: Structures patterned by Blu-ray discs could boost the efficiency of photovoltaic devices

by Matt Davenport

November 26, 2014

| A version of this story appeared in

Volume 92, Issue 48

Even with the advent of streaming video, Blu-ray Discs may yet escape the fate of obsolete Betamax videotape cassettes. A team of engineers at Northwestern University has shown that Blu-ray movies can be converted into inexpensive templates for efficient solar cells (Nat. Commun. 2014, DOI: 10.1038/ncomms6517).

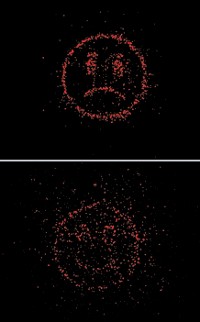

Researchers have long known that arrays of nanostructures can boost solar-cell efficiency. Patterns that are too random or too regular often fail to maximize a cell’s interaction with sunlight. Patterns in a middle ground—known as quasi-random—best facilitate this interaction. But fabricating these arrays is expensive.

Cheng Sun of Northwestern was preparing to pay thousands of dollars for such an array when he and Jiaxing Huang, a colleague in the engineering department, decided to turn to the bargain Blu-ray bin first.

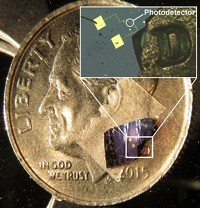

Sun, Huang, and their team realized that Blu-ray Discs are already pocked with quasi-random patterns of nanoscopic pits and islands that correspond to the zeroes and ones of digitized information. These patterns allow Blu-ray players to read sequences of nanostructures without confusing them for fingerprints or scratches. Sequences range in length from about 150 to 525 nm.

These patterns couple strongly with sunlight, Huang says. “Engineers in the Blu-ray industry have been working on these patterns for years,” he explains. “We realized that they’ve been subconsciously doing our jobs.”

By coating recorded discs—featuring such Hollywood fare as “Supercop” and “Family Guy”—with a silicone elastomer, the team created stamps that can be used to transfer patterns to a photoactive polymer called PTB7:PC71BM. Solar cells made using polymers patterned this way absorbed more light and converted it to electricity more efficiently than nonpatterned ones.

“This is a very clever idea,” says Xiang Zhang of the University of California, Berkeley, and director of the Materials Sciences Division at Lawrence Berkeley National Laboratory. The new nanopatterning method, he says, “amazingly works so well and costs so little.”

Computer simulations also suggest this technique could enhance perovskite and silicon solar cells. And Huang suspects its utility won’t end with photovoltaics. “This is a very cheap, very accessible patterning technique,” he says. “I have a hunch there are applications beyond photonics.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter