Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

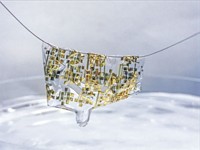

Electronics That Dissolve In The Body

Materials choices are key to making devices that biodegrade harmlessly

by Mitch Jacoby

December 1, 2014

| A version of this story appeared in

Volume 92, Issue 48

Imagine how angry customers would be if their brand-new electronic devices stopped working en masse after just one month—or one week. Such short service life would cause manufacturers’ reputations to tank.

John A. Rogers doesn’t think so. In fact, he’s working to design electronics that break down quickly and do so on cue and in a predetermined way, leaving behind only harmless products. He hopes the strategy will yield new types of implantable electronic devices that dissolve in the body when they are no longer needed, thereby freeing patients from additional surgeries to remove the implant.

Rogers, a professor of materials science at the University of Illinois, Urbana-Champaign, reported on his group’s progress in this area, including in vitro and in vivo studies, on Nov. 11 at the annual AVS science and technology conference in Baltimore.

At the core of this work is the recognition by a number of researchers that common circuit components, including semiconductors, electrodes, interconnects, and insulators, can be made from materials that dissolve in water. Standard electronic materials do not dissolve, or do so extremely slowly.

A silicon structure, for example, may erode in water at a minuscule rate of just 1 nm per day. But as Rogers pointed out, if the structure’s thickness measures only a few nanometers to begin with, not tens of micrometers or more, which is typical, then the slow dissolution rate can be exploited to make a device that will dissolve at a predetermined time.

“That’s an underappreciated aspect of silicon’s chemistry that opens all kinds of opportunities for bioresorbable transient electronics,” he said.

The Illinois group is making such circuitry by coupling ultrathin silicon ribbons with components made from other resorbable materials. Examples include magnesium, iron, and zinc electrodes and interconnects; MgO insulators; and silk-based substrates and circuit boards. Rogers reported that tests show that various types of circuitry made from such materials, including radio-frequency antennae and near-field communication devices, function normally and then dissolve quickly upon exposure to water (Adv. Mater. 2014, DOI: 10.1002/adma.201403164).

He also reported that by choosing materials that dissolve at different rates, a select component of a circuit can be programmed to decompose at a specific time. That change in structure changes the function of the electronic circuit, enabling a single implanted device to serve the functions of multiple devices at preselected times (Adv. Mater. 2014, DOI: 10.1002/adma.201403051).

Just recently, the Illinois team tested their dissolvable electronics in vivo. The group designed an intracranial pressure and temperature sensor of the type used to monitor traumatic brain injury patients. In collaboration with scientists at Washington University in St. Louis, the team implanted these devices in living rats’ brains. Tests show that for roughly one week, the novel devices’ performance matched that of a commercial device. Rogers said the group is now working to extend the functional time frame to a few weeks, consistent with clinical need. He added that long-term histology studies show no adverse biological effects upon complete bioresorption.

Paul Sheehan of the Naval Research Laboratory in Washington, D.C., who attended the presentation, says Rogers’s group takes what appears to be a problem—the dissolution of electronic circuits in physiological conditions—and turns it into a means of reconfiguring the circuit to provide new functionality. He adds, “It’s a clever way to leverage all the electronic components on an implanted circuit.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter