Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Sustainability

Making The Most Of Red Mud

An octogenarian chemist’s latest invention turns hazardous aluminum mining waste into a material for cleaning up water

by Stephen K. Ritter

February 24, 2014

| A version of this story appeared in

Volume 92, Issue 8

Joseph Iannicelli is an inventor unlike any other you might have met. He is the 84-year-old president of Aquafine Corp., a Brunswick, Ga., company that supplies spray-drying and magnetic separation equipment and provides laboratory services for industrial mineral processing. Iannicelli holds dozens of patents for technologies used to purify kaolin, a white aluminum silicate mineral that is essential to making paper, cosmetics, paint, and sorbents for water treatment.

Iannicelli has amassed a small fortune since he graduated from Massachusetts Institute of Technology with a Ph.D. in organic chemistry back in 1955, when he helped develop a biosynthetic method to make penicillin. After working for DuPont on textile fiber polymers and for J. M. Huber Corp. on kaolin, he launched Aquafine in 1971.

In conversations, Iannicelli spontaneously recalls the details of his diverse inventions. His firm baritone leaves the listener hanging on his every word as he weaves a tale to explain how he lately came to be interested in playing with red mud.

Known formally as bauxite residue, red mud is the noxious by-product of the Bayer process for extracting aluminum from bauxite ore. Aluminum mining leaves behind a staggering 120 million metric tons per year of the salty, highly alkaline, heavy-metal-laden material, according to the International Aluminium Institute, a London-based trade organization. The aluminum industry has long tried to find ways to recycle the environmentally problematic red mud. But so far there have been few safe and economical large-scale applications.

“Red mud is a curse,” Iannicelli observes. “There is no shortage of simple, ingenious solutions for dealing with most categories of environmental pollution, including red mud. The deciding factors on implementation are cost and safety.”

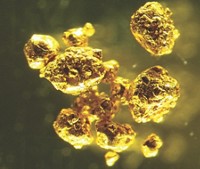

Iannicelli’s solution for red mud is to treat the abundant material with cheap sulfur compounds. Doing so locks in trace metals and improves the material’s sorbent properties, he says, so it can be used for cost-effective wastewater treatment and in other environmental remediation applications. He calls the sulfidized red mud Azorb.

In the Bayer process, strip-mined bauxite is treated with hot caustic soda (sodium hydroxide), which selectively dissolves aluminum from an array of other mineralized metals. The end product is alumina, Al2O3, which is the feedstock for producing aluminum metal.

But for every ton of alumina extracted, more than a ton of red mud is produced. Bauxite processors recycle the caustic soda and pump the residual red sludge into huge settling ponds. When as much water is removed as possible, the material can be chemically treated to lower the pH and planted over with vegetation.

The scourge of red mud burst into the public’s eye in October 2010 when a settling pond in Hungary ruptured. A flash flood of red sludge gushed through several small towns, killing 10 people by drowning and injuring more than 100 others by burning their skin and irritating their eyes and lungs.

Iannicelli isn’t the first person to think about getting his hands dirty with red mud to help prevent such disasters. Australia-based industrial waste management firm Virotec has developed a process to neutralize red mud with copious amounts of seawater or brine. The resulting material is generally used to remediate mining sites, but it is also used as filler to make bricks and as a sorbent to trap metals and phosphorus in wastewater.

Aluminum producer Alcoa has a process to carbonate red mud using CO2 from industrial gas streams. The resulting “red sand” is used to make cement and in road construction. Others have developed processes to recover iron and rare-earth metals from red mud. But so far, only 2 million metric tons of red mud is being repurposed annually—less than 2% of the amount being generated.

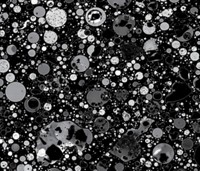

Once aluminum is extracted from bauxite, the remains are a porous matrix of metals—a mineral skeleton, Iannicelli explains. As much as half of red mud is iron oxide, from which it gets its rusty color. Other major components include aluminum, silicon, titanium, calcium, and sodium oxides. The material includes trace amounts of other metals, including radioactive uranium.

With a high surface area, red mud is a natural sorbent capable of grabbing heavy metals and organic contaminants and sequestering them. But red mud can also leach toxic heavy metals, which is an environmental concern.

Iannicelli’s sulfidation process involves treating red mud with sulfur compounds under ambient conditions or with mild heating. Any of a number of sulfur compounds will do the job, he says, including Na2S, (NH4)2S, and H2S. In the sulfidation reaction, sulfur atoms bind to vacant spots on metals throughout the skeletal network, locking the metals into place and preventing them from leaching.

Sulfidation also tunes the red mud so that it has significantly higher sorbent capacity than untreated red mud, Iannicelli says. He has been testing Azorb’s sorbent capabilities in side-by-side tests with untreated red mud using solutions of different metal salts.

Azorb removes better than 90% of most metals from aqueous solutions, Iannicelli says. His team has achieved better than 99% removal rates for metals of concern such as cadmium, chromium, lead, and mercury. The sulfidized red mud is not as efficient at removing arsenic, manganese, and strontium as red mud itself, Iannicelli says. But he suggests mixtures of red mud and sulfidized red mud might be an option for some applications. Once used, the material would be placed in a landfill.

“This work is certainly a very interesting study to detail the removal of a wide range of different species,” says Justin Hargreaves, a chemist at the University of Glasgow, in Scotland. “Particularly interesting is that consideration has been given to the possibility of the red mud systems being sources of contaminants themselves and the application of sulfided and nonsulfided red mud combinations to optimize removal efficacies.”

Hargreaves and his colleagues have been treating red mud with methane, a readily available by-product of oil refining and landfills. Red mud catalytically decomposes methane to form hydrogen and an iron-carbon composite. The Glasgow researchers think the inexpensive magnetic composite material could be used to remove impurities such as arsenic and chromate from drinking water in developing countries.

Iannicelli has also tested Azorb to clean up water discolored with natural dissolved organic compounds, such as tannins and lignin. This is a problem encountered when the effluent of pulp and paper mills is discharged into rivers. Although such water isn’t always considered polluted, when water clarity is unnaturally impacted the effluent is in violation of the intent of clean water laws.

With that in mind, Iannicelli has shown that Azorb readily traps and removes discolored compounds from Okefenokee Swamp water. Iannicelli also has been working with Altamaha Riverkeeper, a nonprofit environmental stewardship organization that is concerned with discolored water in the Altamaha River, which drains central Georgia. The discolored water there mostly comes from a Rayonier wood pulp mill that manufactures cellulose fibers used in plastics and as an absorbent material in products such as diapers. In preliminary tests on the river water, Azorb removed the discolored compounds, Iannicelli says.

Iannicelli also owns a colonial-era rice plantation in Georgia. The plantation is no longer farmed, but it is home to a mobile home park that has its own wastewater treatment facility. As a licensed wastewater engineer, Iannicelli has carried out water treatment tests using Azorb. His team found that Azorb removes phosphorus and fecal coliform bacteria, the major contaminants of concern in wastewater, to below detection levels.

Not content to stop there, Iannicelli had technicians with the Jekyll Island State Park Authority in Georgia test Azorb on municipal wastewater. They obtained similar results, providing an independent confirmation of phosphorus and bacteria removal.

Iannicelli has also talked with scientists at a large coal-fired power plant about the prospects of using Azorb to remove mercury and selenium, the two metals of greatest concern in scrubber gas wastewater.

“There is a long history of attempts to reformat red mud for beneficial use, with none to my knowledge having proved successful on a large scale,” says Ian T. Burke, an environmental scientist at the University of Leeds, in England. Burke remains skeptical that the abundant red mud can safely be used.

Last year, Burke led a team that took a look at three of the most hazardous trace metals in the Hungarian red mud: arsenic, chromium, and vanadium. The researchers found that arsenic and chromium are not in bioavailable states and posed low risk. But vanadium is in the bioavailable V5+ state and could be a long-term problem.

“Many studies that deal with red mud as an absorbent focus on the uptake of metals or nutrients,” Burke continues. “But they do not give enough consideration to the quality of the treated water—that is, is it suitable for discharge to rivers?”

Burke also has questions about the long-term stability of new mineral phases in the sulfidized material and how it will hold up when used as a sorbent. “Much more detailed work seems to be required before this material could actually be used,” Burke believes.

Futility has been the name of the game with red mud, adds geologist Katy Tsesmelis, a communications manager at the International Aluminium Institute. “We receive lots of project proposals that may have a sound scientific basis but could never be scaled up,” Tsesmelis notes. She says there are also lots of attempts made to reuse red mud that never come to light. It’s possible someone already tried sulfidized red mud.

But Tsesmelis emphasizes that the industry continues to invest in research. “The industry as a whole is working hard to remediate and reuse bauxite residue.”

Iannicelli isn’t discouraged by the lack of success so far in using red mud. He now has multiple patents for the sulfidation process and is eager to make commercial quantities of Azorb. He expects the cost to be as little as 10 cents per lb, less than half the cost of similar sorbents. And the first major application might be this year, cleaning up discolored pulp and paper mill effluent.

“I think the time is ripe to turn cheap red mud into an inexpensive material that can help solve some serious environmental problems,” Iannicelli says. “I don’t have all the answers yet. But as a chemist, I want to do good for the chemical industry.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter