Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy

Tailoring An Electrolyte-Electrode Pair For High-Efficiency Lithium-Air Batteries

Electrochemistry: Researchers boost the performance of lithium-air cells by finding the right electrode materials for an ionic-liquid electrolyte

by Prachi Patel

October 30, 2014

As engineers look for ways to power electric cars that can run for a few hundred miles on a single charge, lithium-air batteries present one possible solution. In theory, these batteries can hold five times more energy per weight than currently available lithium-ion batteries. But researchers have struggled to build a Li-air battery that efficiently discharges most of its energy so it can be recharged many times.

By tailoring the oxygen electrode for an ionic-liquid electrolyte, an international team of researchers has now made a Li-air battery that is more efficient, has a higher charge capacity, and can undergo a greater number of charging cycles than previous batteries (Nano Lett. 2014, DOI: 10.1021/nl5031985). The new battery delivers 82% of the energy used to charge it compared with 60 to 70% for most existing Li-air batteries.

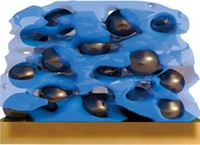

Li-air batteries have lithium metal anodes and porous carbon cathodes through which oxygen flows. For the electrolyte, many researchers favor nonvolatile, heat-resistant ionic liquids—molten salts of positive and negative ions—because electrolytes based on organic solvents can catch fire at high temperatures. But such batteries have been inefficient, last just a few charge-discharge cycles, and have low charge capacities of 1,800 milliampere-hours per gram, at best.

The team—including Bruno Scrosati of Elettrochimica ed Energia, in Rome; Jusef Hassoun of Sapienza University of Rome; Yang-Kook Sun of Hanyang University, in Seoul, South Korea; and Stefano Passerini of Helmholtz Institute Ulm, in Germany—thought they could improve battery performance by finding the right oxygen electrode composition to work with an ionic-liquid electrolyte. They started with a methylpyrrolidinium-based ionic-liquid that Passerini had developed previously. Then they tested different combinations of oxygen electrode materials until they found the ones that worked best for the electrolyte, namely a mixture of carbon black powder and fluorinated polymer coated on carbon paper.

The researchers used the electrode-electrolyte pair to make a coin-cell battery and ran it through a series of standard tests. In addition to the Li-air cell’s 82% efficiency, it had a charge capacity of 4,000 mAh/g and lasted at least 30 cycles without any deterioration in performance.

The team also used electron microscopy to understand the performance of their improved battery. When a Li-air battery discharges, lithium ions produced at the anode move through the electrolyte to the cathode, where they react with oxygen to form lithium peroxide. Although the process should reverse during charging, the peroxide can precipitate on the porous cathode and insulate it. Because not all the lithium ions are reused, the battery efficiency is lower.

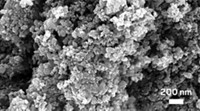

The lithium peroxide particles produced at the cathode from their new battery during discharge were 200 nm wide on average—one-tenth the size of those formed with Li-air batteries that the researchers have made using a different electrolyte. The researchers believe that in their battery lithium ion diffusion is slower, which reduces the size of the lithium peroxide deposits. These smaller particles easily break apart and reconvert to lithium and oxygen, Scrosati says.

Di-Jia Liu, a chemist who studies Li-air batteries at Argonne National Laboratory, says that the reported efficiency “is among the best in the literature” and that the energy capacity of the coin-cell battery is also very good. If these two parameters hold up in larger cells and can be sustained for a higher number of charging cycles, he adds, Li-air batteries would come closer to practical application.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter