Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Polymer Additive Reduces Risk Of Jet Fuel Catching Fire

Polymers: Compounds control the size of mist particles coming off jet fuel, making planes safer

by Bethany Halford

October 1, 2015

| A version of this story appeared in

Volume 93, Issue 39

A new type of polymer fuel additive could reduce the chances of an airplane erupting into a deadly fireball after a crash. The additive is composed of telechelic polymers—polymer chains that reversibly link together through their end groups. They have been shown, at concentrations of 0.3 wt %, to control highly flammable fuel mist, preventing explosions of jet fuel without interfering with normal engine operation.

In 1977, two jumbo jets collided on an airport runway in Tenerife, in the Canary Islands. The resulting fire killed 583 people. The accident prompted scientists to look for ways to make jet fuel safer. Because jet fuel mist is far more flammable than bulk fuel, researchers reasoned that mist-controlling polymers could improve safety. Initial efforts were deemed a failure, however, when in a 1984 field test, a remotely piloted jet carrying a mist-controlling additive burst into flames after a crash.

Virendra Sarohia, a researcher at NASA’s Jet Propulsion Laboratory, had been part of the research project and felt that, despite the fire, not all was lost. In 2002, he approached Caltech chemical engineering professor Julia A. Kornfield and showed her photos from the test indicating that the plane’s plastic windows remained intact after the fire. That prompted Kornfield to begin exploring mist-controlling polymers herself.

The problem with the polymers used in 1984, Kornfield explains, is that they interfered with engine operation. What’s more, these long polymers broke apart while being pumped into the plane and lost their mist-controlling properties.

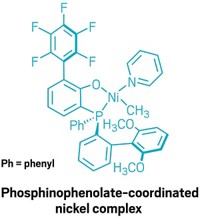

Kornfield’s group used a theoretical model to design polymer additives that would reassemble if sheared apart. The researchers then spent four years trying to synthesize them. The telechelic polymers they finally made have either dibasic or diacidic end groups, which stick to each other like Velcro (Science 2015, DOI: 10.1126/science.aab0642).

“The end groups that work the best are also the simplest,” Kornfield says. “They’re simply carboxylic acid groups as the hydrogen-bond donors and tertiary amines as the hydrogen-bond acceptors.”

“In my mind the most impressive aspect of the work was the choice and introduction of the end groups into their long telechelic polymers,” comments Mitchell A. Winnik, a polymer science expert at the University of Toronto. The end groups make the molecules link up into long linear chains. Also, he says, they seem relatively simple to make.

Kornfield estimates it will take several years for the additives to be approved for use in jet fuel. In the meantime, she says, they have other benefits: In diesel fuel, they reduce soot formation in the engine, and they reduce pumping costs and increase throughput when added to fuel in pipelines.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter