Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Solvent-Free Zeolites

Solid-state hydrothermal processing increases yield of the materials while greatly reducing water use

by Stephen K. Ritter

January 26, 2015

| A version of this story appeared in

Volume 93, Issue 4

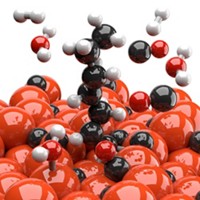

The zeolite family of microporous silica-alumina materials is an invaluable resource for industrial catalysis and separations. The materials are typically made using copious amounts of water or other solvent, which can reduce final yield and generate excessive polluted wastes. An international research team has now reported a simple and economical solvent-free approach to making multiple classes of zeolites that could significantly cut down on environmental concerns. The work was led by Xiangju Meng and Feng-Shou Xiao of Zhejiang University, in China, and Feng Deng of Wuhan Institute of Physics & Mathematics of the Chinese Academy of Sciences, and it included process research and engineering collaborators at BASF (J. Am. Chem. Soc. 2015, DOI: 10.1021/ja5124013). Solvent-free approaches to making zeolites are known, but they usually begin with the hydrated form of silica gel, which limits industrial applications because anhydrous materials are ultimately needed. The new approach involves grinding up anhydrous silica gel with ammonium fluoride and standard alkylammonium zeolite templates at room temperature and then heating the mixtures as high as 240 °C. The fluoride helps drive crystallization of anhydrous zeolites, the researchers note. Compared with conventional hydrothermal synthesis, the new solvent-free approach simplifies procedures and enhances yields.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter