Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy

Making Battery Electrodes From Packing Peanuts

ACS Meeting News: Chemical engineers carbonize foam packaging to produce materials for lithium battery electrodes

by Michael Torrice

March 24, 2015

Packing peanuts make shipping fragile objects easy. But the puffy particles become a wasteful nuisance once the shipment is complete. Now researchers report a method to turn them into something useful.

The chemical engineers carbonize the foam packaging and use the resulting carbon microsheets to construct lithium battery anodes that rival the performance of conventional graphite ones.

Vinodkumar Etacheri, a postdoc in the lab of Vilas G. Pol of Purdue University, presented the work Sunday in the Division of Environmental Chemistry at the American Chemical Society national meeting in Denver.

The idea to work with packing peanuts came to Pol last year when he was setting up a new lab. “We were getting boxes filled with packing peanuts all the time with the devices and chemicals we were buying,” Pol told C&EN. In the U.S., only a small percentage of the polystyrene packaging gets recycled, Pol said, so he wanted to find a new use for them.

The anodes of a lithium-ion battery are usually made from graphite. As the battery charges and discharges, the graphite absorbs and releases lithium ions.

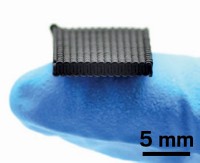

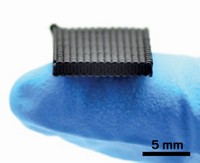

To turn the packing peanuts into battery anode materials, Pol’s team carbonized the particles. The researchers first heated the peanuts from 500 to 900 ºC for a couple of hours under an atmosphere of argon. They also added a metal-salt-based catalyst when carbonizing the polystyrene particles. Then they ground up the carbonized peanuts into a powder that consists of microsheets of carbon.

The researchers made anodes from the powder and tested their performance in coin cell batteries, similar to ones that power wristwatches. They put the batteries through a series of charging and discharging cycles.

Compared with batteries that have a conventional anode, the Purdue team’s batteries could charge faster because the microsheets are thinner than graphite, Pol told C&EN. Also, the storage capacity of the peanut anodes was about 13% greater than the theoretical capacity for graphite anodes. This is because the microsheets formed a more disordered, porous network compared with graphite, allowing for greater absorption of lithium ions.

The process of turning the peanuts into anode materials has huge potential for success, said Sherine O. Obare of Western Michigan University, and chair of the session in Denver. She pointed out that the carbonization method probably would work with any material containing polystyrene.

Pol told C&EN that his team is looking for funding to scale up the peanut carbonization process. The researchers are also looking into other uses for the carbon powder, such as printer toner.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter