Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

How Laser Cooling Is Changing The Ion-Beam Game

Supercold atoms could lead to smaller beams of more atomic flavors for electronics and spectroscopy

by Matt Davenport

January 25, 2016

| A version of this story appeared in

Volume 94, Issue 4

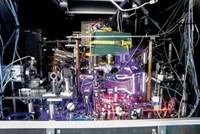

There’s no mistaking it: Jabez J. McClelland’s lab at the National Institute of Standards & Technology is a physics lab.

Mechanical whirring of indeterminate origin? Check. Shiny stainless steel chambers wrapped in coils of copper wire? You bet.

Lasers? Oh yes, there are lasers.

There is so much lasing going on that McClelland has hidden some of the optics to make the instrument he’s working on look less intimidating to people who aren’t laser-loving physicists.

But this machine, like so many born in physics labs, has great promise for chemistry. This machine makes ion beams.

Researchers of all stripes have long relied on narrowly focused ion beams to sculpt and probe materials at the nanoscale. This sculpting is used in a variety of applications, such as patterning microelectronic devices or extracting minuscule amounts of material for further analysis by mass spectrometry or other techniques. Ion beams can also image samples using technology very similar to what’s used in electron microscopy.

But the choice of elements capable of providing the ions for the beams is limited. The tool developed at NIST adds roughly one-fifth of the periodic table to that portfolio, McClelland tells C&EN.

NIST’s technology, which was recognized by the magazine Microscopy Today as one of the top innovations of 2015, could help push the frontiers in energy research, analytical chemistry, and computer chip development.

Gallium is the workhorse of ion beams, but helium and neon have also joined its ranks. Each ion excels at certain things.

Gallium, for instance, is heavier than helium and is more effective at blasting away atoms from a target. Helium, on the other hand, is the better ion for imaging.

The NIST technology will enable researchers to explore the advantages of other ions and could lead to tighter ion beams for creating and resolving ever smaller features, McClelland says. NIST’s ion-beam prototype, which was developed in conjunction with the microscopy company FEI, is already on par with current gallium beam instruments in terms of resolution, he adds.

The pivotal difference between the NIST instrument and existing beams is how they generate ions. Instead of using powerful electric fields to rip charged particles from cusps of molten gallium or puffs of noble gases, the NIST prototype accelerates particles from a cold atomic cloud.

To create the cloud, the team built what’s known as a magneto-optical trap. The trap uses a magnetic field and six converging laser beams to confine atoms to a spot about 20 µm in diameter. Atomic motion is so restricted in this trap that the cloud’s temperature is less than one-thousandth of a degree above absolute zero.

A final laser then fires into the cloud, zapping electrons away from the atoms and allowing the resulting ions to be hurled at a target by a modest electric field.

This ion source—the magneto-optical trap ion source, or MOTIS (pronounced MOE-tiss)—could generate ion beams from about 25 different elements, McClelland says. Each element would require a laser of a particular wavelength, but the principle is general, compared with existing ion beams, which are customized for specific elements.

Laser cooling works really well with lithium, so it was a sensible element to start with for the NIST prototype, McClelland tells C&EN. Lithium was also particularly interesting to his colleagues in energy research.

“The energy people were like, ‘Do you know what you have here? This could be a fantastic tool for lithium-ion battery research,’ ” McClelland recalls.

Stephen J. Harris, a lithium-ion battery researcher at Lawrence Berkeley National Laboratory, is one of those people.

Harris says the beam could help measure one of the most elusive quantities in lithium-ion battery research: lithium’s diffusion coefficient. This value tells researchers how quickly ions move in battery electrodes.

Measuring this quantity would allow researchers to intelligently make the necessary trade-off between how quickly a battery charges and how much charge it can store, Harris explains. “If you don’t know the diffusion coefficient, you’re probably going to make a bad trade-off.”

Researchers typically estimate diffusion coefficients using electrochemistry. As a voltage pushes swarms of lithium ions through an electrode, researchers record electric current and try to extract the coefficient from those measurements.

The lithium-ion beam could lead to a more direct measurement by precisely and controllably injecting lithium ions into electrodes. Using secondary ion mass spectrometry, or SIMS, researchers could then follow the lithium ions through the electrode to measure the diffusion coefficient “unambiguously, cleanly, and accurately,” Harris says.

McClelland points out that laser-cooled ion sources could pull double duty in such applications, providing the ions needed for SIMS.

But MOTIS isn’t the only possible new ion source for analytical techniques such as SIMS or even for more conventional ion beams. While working at NIST with McClelland, Adam V. Steele and Brenton Knuffman invented an improved low-temperature ion source, or LoTIS. They’ve since launched a start-up around this innovation called zeroK NanoTech.

Instead of ionizing a cold atomic cloud, Steele and Knuffman are working toward ionizing a colder and denser atomic stream. In theory, this would shrink an ion beam’s diameter, or spot size, Steele says.

And smaller spot sizes are in demand, especially in the semiconductor world, he adds. When computer chip manufacturers create a prototype that doesn’t work as planned, they don’t usually scrap the thing and start over. Instead, they snip defective electronic connections within the chip’s nanoscopic architecture with a focused ion beam then draw in the correct connections with ion-beam-assisted metal deposition.

As chip components get smaller, companies will need more precise ion beams to perform this circuit editing, Steele says. “We look forward to proving the LoTIS can deliver subnanometer spot sizes.”

He and Knuffman launched zeroK with support from a National Science Foundation Small Business Innovation Research award and have since secured funding from a large semiconductor company, which the duo declined to name. They are working to complete a prototype ion source this year.

Meanwhile, back at NIST, McClelland and his team are working on a second-generation lithium-ion beam, this time using equipment from another company, Zeiss. “We’re equal-opportunity collaborators,” he says of the swap from FEI.

He hesitates slightly when he’s asked what he wants to do next with the tool. It’s the hesitation of someone who possesses something new.

Conventional instruments generate ions from atoms with loads of kinetic energy. The NIST researchers rob atoms of their energy using lasers. They’ve thus opened up a field of low-energy ion-beam microscopy and nanomachining, McClelland says.

Compared with what’s out there, “we’re in a different space entirely,” he says. “I think there’s a lot of interesting science we’ll be able to explore.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter